Application of small coater in gel coating

In recent years, gel patches have been widely used in the field of medical and daily care due to their portability, ease of use, and remarkable effects. The small coater plays an important role as a key equipment for the production of gel paste. This article will discuss in detail the application of small coating machine in gel paste from the aspects of its principle, structure, characteristics, application scenarios and practical cases.

The working principle of the small coater

A small coater is a device that evenly coats a liquid or semi-liquid coating on the surface of a substrate through mechanical or electronic control. The basic working process consists of three main steps: coating, drying and rewinding. First, the paint is evenly distributed on the surface of the substrate by means of a coating head or nozzle. Next, the solvent in the coating is evaporated by a drying device (such as hot air drying, infrared drying, etc.) to solidify the coating on the surface of the substrate. Finally, the substrate that has been coated and dried is rewound into a roll for further processing and use.

Structure and characteristics of a small coater

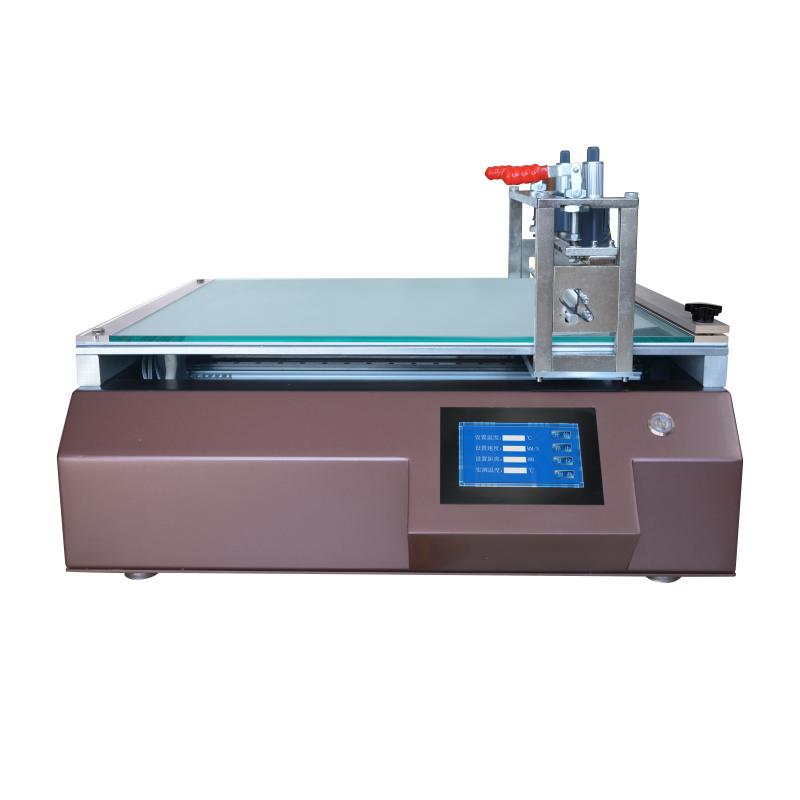

The small coater is usually composed of five main parts: feeding system, coating system, drying system, transmission system and control system. The feeding system is responsible for storing and transporting the paint, including bins, pumps, piping, etc. The coating system is the core part, including the coating head, nozzle, coating roller, etc., which determines the uniformity and thickness of the coating. The drying system includes a Drying Oven, heater, fan, etc., which is used to quickly dry the coating. The drive system is responsible for the conveying and positioning of the substrate, including conveyor belts, guide rollers, motors, etc. The control system includes PLC controllers, sensors, displays, etc., which are used to control and monitor the entire coating process.

The small coater has the characteristics of compact structure, easy operation, high precision and strong adaptability. It has a small footprint and is suitable for laboratory and small-scale production; Intelligent control system, simple operation and easy to use; Through the precision coating head and control system, the uniformity and thickness consistency of the coating are ensured; Suitable for a wide range of substrates and coatings with a wide range of applications.

The application of small coaters in applying gel pastes

Paint selection

The main components of gel patches are drugs, matrices and additives, and the common matrices are water-soluble polymer materials and fat-soluble polymer materials. Depending on the pharmaceutical ingredient and treatment needs, it is important to choose the right coating formulation. Common water-soluble coatings include polyvinyl alcohol (PVA), hydroxypropyl methyl cellulose (HPMC), etc., which are suitable for water-soluble drugs; Fat-soluble coatings include polyacrylic acid (PAA), silicone, etc., which are suitable for fat-soluble drugs.

Coating process

The optimization of the coating process is a key part of ensuring the quality of the gel paste, including the control of parameters such as coating speed, coating thickness, drying temperature and drying time. The coating speed affects the uniformity and thickness of the coating and is generally adjusted according to the characteristics of the substrate and the coating. The thickness of the coating directly affects the drug content and application effect of the plaster, which is usually controlled by adjusting the gap and pressure of the coating head. The drying temperature and time affect the curing quality and production efficiency of the coating and need to be set according to the volatility and curing characteristics of the coating.

Application examples

A medical device company uses a small coater for the production of gel patches. By optimizing the coating process, the company has succeeded in producing a uniform and consistent thickness gel patch that has been well received by the market. The specific process parameters are as follows: the coating speed is 10 m/min, the coating thickness is 100 microns, the drying temperature is 60 degrees Celsius, and the drying time is 10 minutes.

Another example is the experimental study of a new type of drug patch in a drug discovery laboratory using a small coating machine. By precisely controlling the coating thickness and drying time, the laboratory has successfully prepared a variety of plasters with different drug content and drug release characteristics, which provides important data support for the development of new drugs.

conclusion

The small coater has a promising application in applying gel pastes, and its compact structure, ease of operation and high-precision coating effect make it a device for laboratory research and small-scale production. By optimizing the coating selection and application process, the quality and application of gel plasters can be significantly improved.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Experimental application of water-based paints on film laminating paper by laboratory coater

- 5Experimental coater application case video of liquid silica gel on release paper

- 6Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 7Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

- 8Application of small coater in polyimide slurry

- 9Application of laboratory coater coating aluminum oxide paste on PET film