Systematic understanding of coil isolation film coater

A coil separator coater is a device used to coat a separator film on the surface of a coil. With the continuous progress of industrial technology, the application range of coating machines is becoming more and more extensive, especially in the fields of packaging materials, electronic components, building materials, etc., coil separator coating machines play an important role. This article will introduce in detail the working principle, structural characteristics, technical parameters and application fields of the coil separator coating machine.

The working principle of the coil separator coating machine

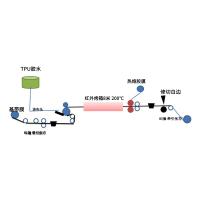

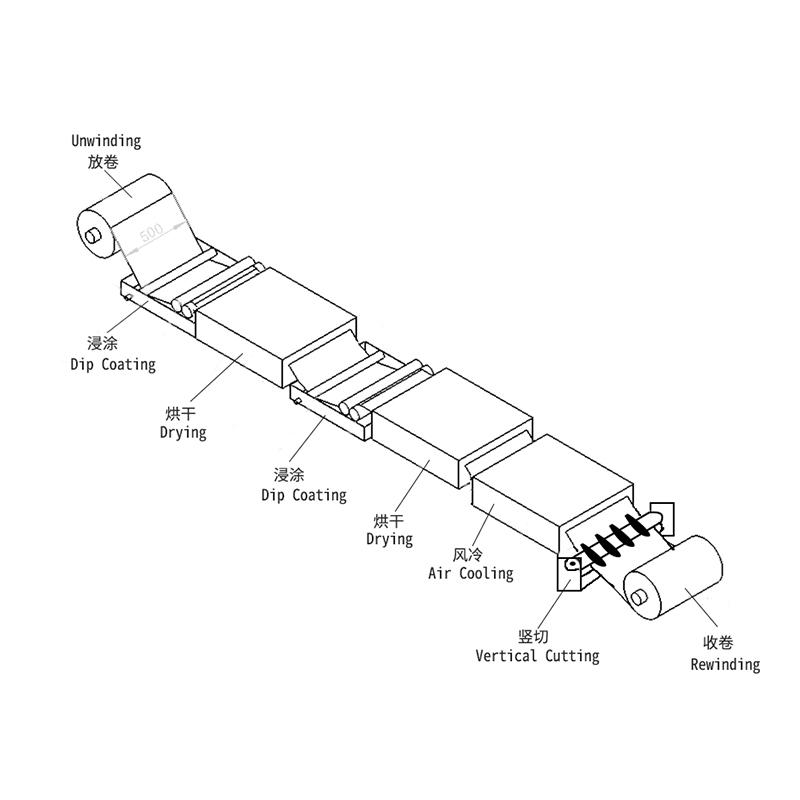

The working principle of the coil separator coating machine mainly includes: firstlyThe coil material enters the coating machine through a feeding device, usually with an automatic feeding system to ensure that the material enters the coating area continuously and evenly. againThe coater evenly coats the surface of the coil through the applicator head. The coating methods mainly include knife scraping coating, roller coating and spraying cloth. The position and angle of the coating head can be adjusted according to specific needs to ensure the uniformity and thickness of the coating. And thenThe coated coil needs to go through a drying and curing process, usually using hot air drying, infrared drying or ultraviolet drying to make the coating cure quickly and ensure the adhesion and stability of the coating.Finally, the coated coil is rewound by the winding device to form the finished coil. The receiving process needs to ensure that the coil is flat and tight to avoid affecting product quality due to loose or uneven material.

Structural features of coil separator coating machine

The structural design of the coil separator coating machine directly affects its work efficiency and coating quality. The main structural features are as follows:

The frame is the main structure of the coater and is usually made of high-strength steel to ensure the stability and durability of the equipment. The frame design needs to consider shock absorption and vibration resistance to improve coating accuracy.

The coating head is the core component of the coating machine, and its design and manufacturing accuracy directly determine the coating quality. The type and number of coating heads can be selected and adjusted according to the coating material and process requirements.

The drive system of the coating machine usually includes a motor, a reducer, a transmission mechanism, etc. Modern coating machines mostly use servo motors and precision reducers to achieve high-precision and controllable coating operations.

The control system of the coating machine is the key to realize the automatic operation, usually using PLC (programmable logic controller) and touch screen control, with various sensors, to achieve real-time monitoring and adjustment of the coating process.

The drying system is a critical part of ensuring the curing of the coating, and the design needs to take into account factors such as drying speed, temperature control, and energy consumption. Modern coating machines mostly use energy-saving and environmentally friendly drying technology to reduce operating costs.

Technical parameters of coil separator coating machine

The technical parameters of the coil separator coating machine directly affect its application performance, and the main technical parameters include:

1) Coating width:

Coating width refers to the maximum width of the coil that the coating machine can handle, which is usually designed according to the specific application requirements, and the common specifications are 600mm, 1200mm, 1600mm, etc.

2)Coating speed:

Coating speed refers to the length of coating completed by the coater per unit of time, usually measured in meters per minute (m/min). The coating speed affects the production efficiency, and modern coaters have the function of adjustable speed.

3)Coating thickness:

Coating thickness refers to the thickness of the coating on the surface of the coil, usually measured in micrometers (μm). The control accuracy of coating thickness directly affects the coating quality, and modern coating machines mostly have high-precision thickness control functions.

4)Drying temperature:

Drying temperature refers to the operating temperature of the drying system during the drying process, usually measured in degrees Celsius (°C). The precision of the control of the drying temperature affects the curing effect of the coating.

5)Winding Diameter:

The winding diameter refers to the maximum coil diameter of the coil during the receiving process, usually in millimeters (mm). The winding diameter affects the receiving capacity of the equipment and the specifications of the finished coil.

Fields of application

Coil separator coating machines are widely used in many industries, and the main application areas include:

In the field of packaging materials, coil separator film coating machines are widely used to produce moisture-proof, waterproof, oil-proof and other functional packaging films, which are widely used in food, medicine, chemical and other industries.

In the field of electronic components, coil separator coating machines are used to produce electromagnetic shielding films, insulating films, etc., which are widely used in the manufacturing process of electronic products such as mobile phones, computers, and home appliances.

In the field of building materials, membrane separator coating machine is used to produce waterproof membrane and heat insulation film, which are widely used in building waterproof, moisture-proof, energy-saving and other projects.

The automobile industry uses coil separator film coating machine to produce explosion-proof film, heat insulation film, etc., which are widely used in automotive glass, body protection, etc.

In the field of medical devices, coil separator film coating machines are used to produce medical protective films, disinfection films, etc., which are widely used in the packaging and protection of medical devices.

In short, the coil separator coating machine is an important equipment in modern industrial production, and the working principle, structural characteristics and application fields of the coil separator coating machine can also be systematically understood through the above content.

- 1The principle and application of miniature coil spraying machine

- 2Analysis of PVC coil composite coater technology

- 3Analysis of extrusion hot-melt adhesive coater technology and comparative study of coil hot-melt adhesive coater

- 4Detailed explanation of heating coil coater technology and introduction of heating system

- 5Comparison between hot-melt adhesive double-sided coater and hot-melt adhesive coil coater

- 6Epoxy coil coater technology and selection method

- 7Selection method and maintenance technology of waterproofing membrane coater

- 8Polymer coil coater vs sheet coater: technology showdown

- 9Self-adhesive coil coater technology principle, operation and maintenance