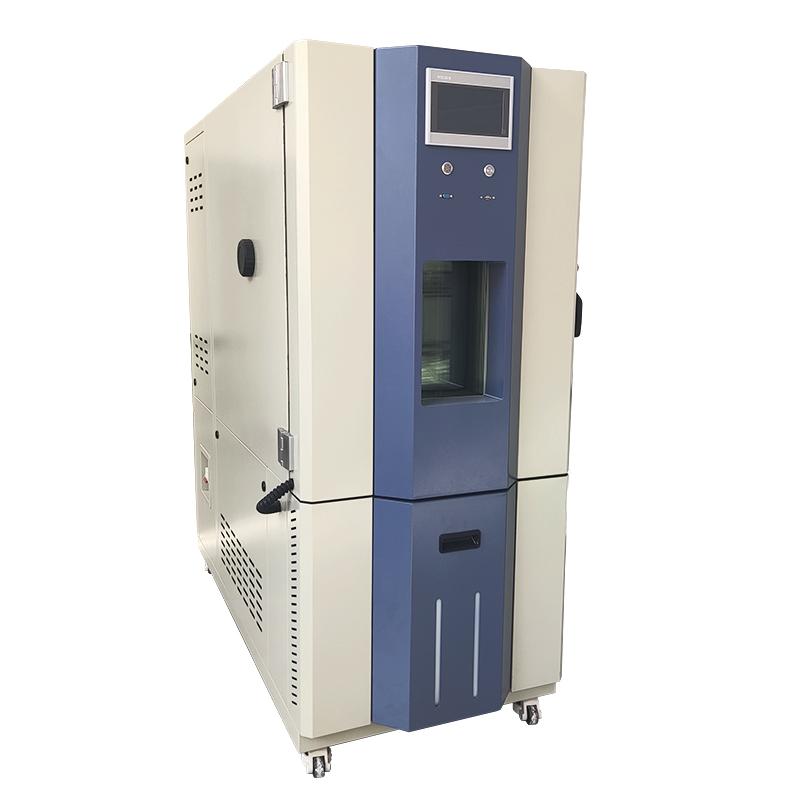

Humidity cabinet test equipment

In modern industrial production and scientific research, the influence of environmental conditions on product performance and reliability cannot be ignored. As an important tool for simulating high temperature and high humidity environment, damp heat test equipment is widely used in the performance evaluation of machinery industry, instrumentation, electrical and electronic products, their components and materials. This article will introduce in detail the use, structural principle, technical indicators, usage methods, common faults and maintenance of constant damp heat test equipment, and provide comprehensive technical guidance and reference for users of NBCHAO.

1. Use

The constant damp heat test equipment is mainly used to assess the performance of mechanical industrial products, instrumentation, electrical and electronic products and their components and materials under constant temperature and high humidity. The main function of this type of test equipment is to evaluate the moisture mechanism of the sample through the adsorption or absorption of water vapor.The constant damp heat Test Chamber is divided into two types: with and without cold source. Users should choose the right equipment according to the technical indicators such as temperature and humidity range, accuracy and studio size.Constant damp heat Test Chamber without cold source, such as constant temperature and Humidity Chamber, temperature and humidity control chamber, hot flash chamber and Humidity Chamber, etc. Generally, this type of equipment has a narrow range of temperature and humidity, and is mainly used for high temperature and high humidity constant test. bringThe cold source constant damp heat Test Chamber is usually called low temperature constant temperature and Humidity Chamber, which has a wide range of temperature and humidity, and is suitable for a variety of test conditions such as high temperature and high humidity, high temperature and low humidity, low temperature high humidity and low temperature and low humidity, and can also be used as a low Temperature Test Chamber.

Second, the structural principle

The basic structure of the constant temperature and Humidity Chamber is mainly composed of two parts: the main engine and the independent electrical control cabinet.The upper part of the main engine is the studio, and the lower part is the refrigeration unit. The studio is generally made of stainless steel plates, and the interior is equipped with cooling evaporators, heaters and humidification holes to form a circulating convection to ensure uniform temperature and humidity in the studio. PassThe electrical control cabinet controls the heating, cooling, and humidification functions inside the main unit.The working principle is to control the operation of heaters, coolers and humidifiers by comparing the input signal with the set value of the temperature and humidity meter, so as to keep the temperature and humidity in the studio constant.

3. Technical indicators

There are many main product technical indicators on NBCHAO Mall, which can be referred to at will. The verification standards and methods can be carried out in accordance with the national standard GB-5170.5 "Verification Method for Basic Parameters of Environmental Test Equipment for Electrical and Electronic Products - Constant Damp Heat Test Equipment".

At the beginning of the operation, the specimen should be warmed and then gradually humidified to prevent condensation on the surface of the specimen. Relative humidity direct-reading indicator regulatorDisplays dry-bulb temperature and relative humidity values. In the case of dehumidification, the setting screw can be adjusted to set the desired humidification and dehumidification conditions.Use a dehumidifier instead of a cooler to work, and then use a heater to balance the temperature control, and a humidifier to maintain high humidity.

Fourth, how to choose

Choosing the right constant damp heat test equipment is critical to ensuring the validity and accuracy of the test. Here are some key factors and steps for users to refer to when making a purchase:

1. Determine the test requirements

Determine the minimum and maximum temperatures required for the test. For example, a high-temperature test may range between 50°C and 100°C, while a low-temperature test may need to reach -20°C or less.

Determine the minimum and maximum relative humidity required for the test. In general, a high humidity test may require a humidity range of more than 90% RH.

Consider the size, quantity, and weight of the sample to be tested to select the appropriate studio size and weight capacity.

Confirm whether it is necessary to perform tests under multiple environmental conditions at the same time, such as high temperature and high humidity, high temperature and low humidity, low temperature and high humidity, and low temperature and low humidity.

2. Understand the type of equipment

Depending on your needs, you can choose a constant damp heat Test Chamber with or without a cold source.NobringThe cold source equipment is suitable for high temperature and high humidity constant test, such as constant temperature and Humidity Chamber, temperature and humidity control chamber, hot flash chamber and Humidity Chamber. This type of equipment has a narrow range of temperature and humidity and is mainly used for testing under specific environmental conditions.bringThe cold source equipment is suitable for testing under a variety of environmental conditions, such as low-temperature constant temperature and Humidity Chambers. It has a wide range of temperature and humidity and is widely used, and can carry out a variety of tests such as high temperature and high humidity, high temperature and low humidity, low temperature and high humidity and low temperature and low humidity.

3. Consider technical indicators

Temperature control accuracy

High-precision temperature control ensures the accuracy of test results, which usually requires temperature fluctuations within ±0.5°C.

Humidity control accuracy

Humidity control accuracy is equally important, and humidity fluctuations are typically required to be within ±2%RH.

Uniformity

Ensure that the temperature and humidity in the studio are evenly distributed to avoid local temperature and humidity differences.

Heating, cooling, and humidification capabilities

Constant damp heat test equipment plays a key role in the assessment of the environmental suitability of various industrial products. By understanding its use, structural principles and technical specifications, users can better select and use such equipment. At the same time, mastering the correct use methods and maintenance skills can effectively extend the service life of the equipment and ensure the accuracy and reliability of the test results.

- 1GB/T 10586-2006 Detailed explanation: Core technical indicators and acceptance specifications for damp heat Test Chamber

- 2Damp heat testing chamber and low-Temperature Test Chamber

- 3Application of Constant Temperature and Humidity Chamber in Lithium Battery

- 4Humidity chamber FAQ and its solution

- 5Humidity chamber FAQ, calibration method, precautions

- 6Humidity chamber FAQ calibration method

- 7Humidity chamber FAQ and correct calibration method

- 8Application of Humidity Chamber in Polymer and composite industry

- 9Application of Humidity Chamber in Photovoltaic industry