Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

With the continuous development of lithium battery technology, the coating process plays a vital role in battery manufacturing. Especially in the process of coating lithium battery slurry on copper foil to make positive and negative electrode pieces, choosing the right small coating machine can not only improve production efficiency, but also ensure the stability of product quality. This article will discuss in detail the technical requirements for small coaters to coat lithium battery slurry on copper foil, and introduce their applications in several fields.

Technical requirements

Here are some of the key technical requirements when using a small coater for lithium battery slurry coating:

1. Coating uniformity

Coating uniformity is critical to battery performance. During the coating process, it is necessary to ensure that the lithium battery paste is evenly distributed on the copper foil to avoid different thicknesses. Coating thickness control is also very important, usually within ±2-3 microns. Different thicknesses of coatings can affect the energy density and cycle life of the battery, so precise control of the coating thickness is required.

2. Coating speed

The speed of the coater should be stable to ensure that the slurry is evenly applied and to avoid coating defects. The stability of the coating speed ensures the uniformity of the coating, while the adjustability of the coating speed can be adjusted according to the characteristics of the slurry and the coating requirements. Different slurries and process requirements may require different coating speeds, so the coater needs to have the flexibility to adjust the speed.

3. Coating environment

The cleanliness of the coating environment and the control of temperature and humidity are also important factors affecting the coating quality. Coating operations are carried out in a clean room or in a clean environment to avoid impurities from mixing into the slurry or coating. The presence of impurities can affect the performance of the battery and may even trigger safety issues such as short circuits. At the same time, the temperature and humidity of the coating environment are controlled to prevent the slurry performance from being affected by the environment. Changes in temperature and humidity will affect the viscosity and coating effect of the slurry, which in turn will affect the performance and consistency of the battery.

4. Slurry characteristics

Make sure that the viscosity of the slurry is moderate for easy and uniform application. Generally speaking, the viscosity of the slurry needs to be controlled in the range of 1000-3000cP. Too high or too low viscosity can affect the coating effect and the uniformity of the coating. In addition, it is necessary to ensure the stability of the slurry during the coating process and to prevent delamination or sedimentation. Poor slurry stability will lead to uneven coating, which will affect battery performance.

5. Copper foil treatment

Before coating, ensure that the surface of the copper foil is clean and free of dirt, and if necessary, perform surface pretreatment (such as cleaning or surface roughening) to enhance the adhesion of the coating. Improper surface treatment can lead to poor coating adhesion and affect the service life of the battery. In addition, the tension of the copper foil needs to be kept stable during the coating process to prevent wrinkles or slackening. Unstable tension can lead to uneven coating and affect battery performance.

6. Drying process

The post-coating drying process requires a controlled temperature, usually in the range of 100-120°C, to ensure that the coating dries evenly and does not crack. Improper temperature control can lead to cracking or incomplete drying of the coating, affecting battery performance. According to the coating thickness and slurry characteristics, the drying time is adjusted appropriately to ensure that the coating is completely dry. Drying too short will cause the coating to have too high water content, which will affect battery performance and safety.

By meeting the above technical requirements, it can be ensured that the coating quality and consistency meet the expected standards in the process of coating lithium battery slurry on copper foil, and the positive and negative electrode pieces with stable performance can be produced.

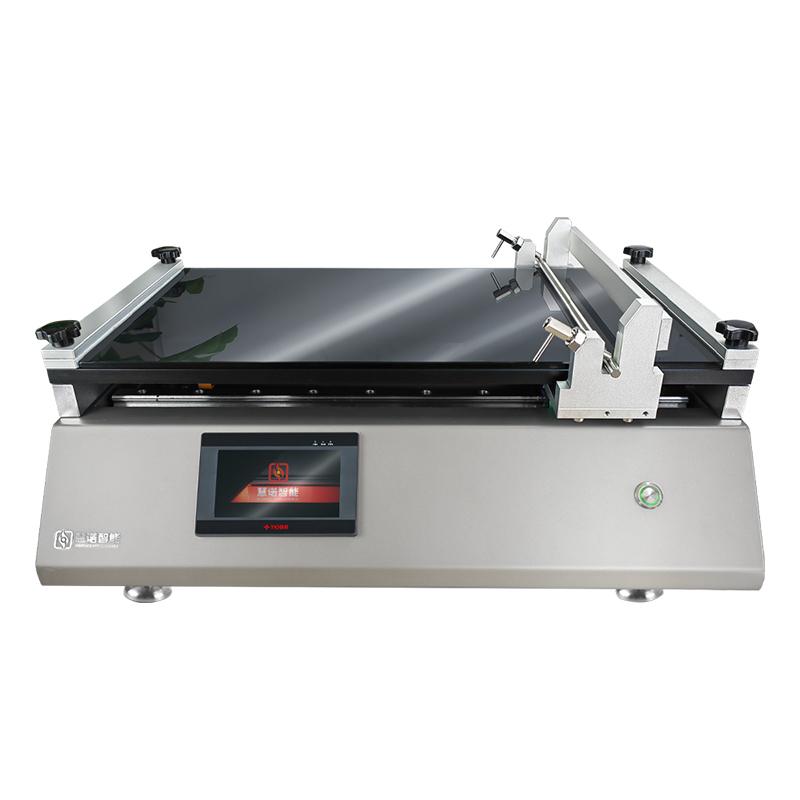

Applicable coater type

When coating lithium battery slurry on copper foil, choosing the right coater is critical to coating quality and production efficiency. The following coater types are suitable for this application:

1. Groove die coater

The groove die coater has the advantage of high coating accuracy and is suitable for high viscosity slurries. It can achieve uniform coating thickness and is suitable for large-area coating. Groove die coaters are widely used in the manufacture of lithium battery pole pieces, especially for occasions that require high precision and consistent coating.

2. Scraper coater

The squeegee coating machine has a simple structure and is easy to operate. Suitable for medium viscosity slurries with adjustable coating thickness. Drawdown blade coaters are suitable for laboratory research and small-scale production, allowing for quick adjustment and testing of different formulations.

3. Wire rod coating machine

The wire rod coating machine is the same as the scraper coating machine, the structure is relatively simple, and the operation is convenient, the thickness of the coating film is controlled by the wire rod with different rod numbers, and the accuracy can be as high as 1 micron, which is suitable for laboratory coating film proofing.

4. Gravure coating machine

Gravure coaters have a fast coating speed and are suitable for slurries with low to medium viscosity. It is able to provide a uniform coating and is suitable for large-scale production. Gravure coating machine is used for mass production of lithium battery pole pieces, with high efficiency and suitable for continuous production.

5. Spray coater

The spray coater has the advantage of high flexibility and is suitable for slurries of various viscosities. It enables precisely controlled coating patterns. Spray coaters are used for the coating of complex shapes and irregular surfaces, and are suitable for special applications or research.

6. Roll-to-roll coater

The roll-to-roll coating machine is suitable for large-scale continuous production, with a high degree of automation and high production efficiency. It enables controllable coating speed and thickness, and is widely used in the industrial production of lithium battery pole pieces, especially where high throughput and consistent coating are required.

The following options are recommended:

Laboratory research – the wire Bar Coater and the drawdown blade coater are a good choice because of their ease of operation, easy adjustment of parameters, and suitability for testing a wide range of formulations and processes.

Small- and medium-scale production——Groove and gravure coaters are suitable options that provide high coating accuracy and consistency.

mass production——Roll-to-roll coater isSuitableChoice, which can achieve efficient continuous production and adapt to the needs of high-volume production.

Considering the accuracy, coating thickness control, production efficiency and application scenarios of the coating machine, selecting the right equipment can significantly improve the production quality and efficiency of lithium battery pole pieces.

Fields of application

The application field of small coating machine for coating lithium battery slurry on copper foil is very wide, mainly including the following aspects:

1. Laboratory research and development

Small coaters play an important role in laboratory research and development. In new materials research, it is used to study the properties of novel electrode materials and electrolytes, including high-energy-density materials and novel electrolyte formulations. Laboratory research is the basis for the innovation of lithium battery technology, and the optimization of the coating process can provide important support for the development of new materials. In addition, small coaters are also used to develop and optimize coating process parameters such as slurry formulation, coating speed, drying conditions, etc., to improve battery performance and production efficiency. By continuously optimizing the coating process, the energy density, cycle life and safety of the battery can be improved. Small coaters are also used to manufacture lab-scale prototype batteries to verify the feasibility and performance of materials and processes. Testing and validation of prototype batteries is a critical step in commercial production.

2. Small- and medium-scale production

In small and medium-scale production, small coaters are used to produce small batches of customized batteries, such as special batteries for special electronic devices, power tools, medical equipment, etc. Custom production of small batches requires high flexibility and precision, and the quality of the coating process directly affects battery performance. In addition, small coaters are also used for product testing and validation, producing batteries for new products such as new electronics, electric vehicles, etc. for testing and validation. Testing and validating products before they are marketed ensures their reliability and safety.

3. Universities and research institutes

In universities and research institutes, small coaters are used in education and training to help students and researchers understand lithium battery manufacturing processes and technologies. Through hands-on operation of the coating machine, students and researchers can gain a deeper understanding of the manufacturing process and key technologies of lithium batteries. In addition, small coaters are used for experiments and data collection in scientific research projects, driving innovation and development in battery technology. The success of a research project often depends on the precision and stability of the coating process.

4. Start-ups and small manufacturers

In the initial stage of small-scale production of start-ups, small coaters are used to meet the market demand for new lithium-ion battery products. Start-ups need to respond quickly to market demands, and small coaters can provide efficient production support. In addition, the small coater also helps small manufacturers to develop new products and pilot production of small batches, and to respond quickly to market demand. With small-scale production, companies can validate product designs and processes, laying the groundwork for large-scale production.

5. Special Applications

In some special applications, such as aerospace, military, diving equipment and other fields, small coaters are used to produce batteries that require specific properties and shapes. Special applications have extremely high requirements for battery performance, and the quality of the coating process is directly related to the reliability and safety of the battery. In addition, the small coater is used for technical demonstrations and demonstrations to help customers and investors understand product features and benefits. Through on-site demonstrations and demonstrations, companies can demonstrate their technical strength and product innovation capabilities.

6. Quality control and testing

During the production process, small coaters are used to monitor and optimize the coating process to ensure consistent product quality. The monitoring and optimization of the production process can improve product quality and reduce production costs. In addition, the small coater is used to check and test the quality of the electrode sheets during the production process to ensure that they meet the specifications. Quality inspection and testing is an important part of the production process, which can ensure the qualification rate and reliability of products.

Through the application of these fields, small coaters can not only help researchers and enterprises develop and optimize lithium battery technology, but also promote the application and development of lithium batteries in various industries. Choosing the right small coater and strictly complying with the technical requirements can ensure the quality of the lithium battery slurry coated on the copper foil, improve the performance and reliability of the lithium battery, and meet the diverse needs of the market.

- 1Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 2Experimental application of water-based paints on film laminating paper by laboratory coater

- 3Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 4Application of small coater in gel coating

- 5Application of small coater in polyimide slurry

- 6Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 7Experimental application of small laboratory coater coated with perfluorosulfonic acid on PET film

- 8Selection and experimental application of small coater coated with viscous liquid on non-woven fabric

南北潮

- 9Application of laboratory coater in EVA hot-melt adhesive