One article introduces RDS Applicator rod type and FAQ

RDS coating rods are an indispensable tool in coating applications and are designed to ensure accurate and consistent film thickness. Depending on the coating requirements and viscosity, RDS offers several types of coating rods.

Type of coating rod

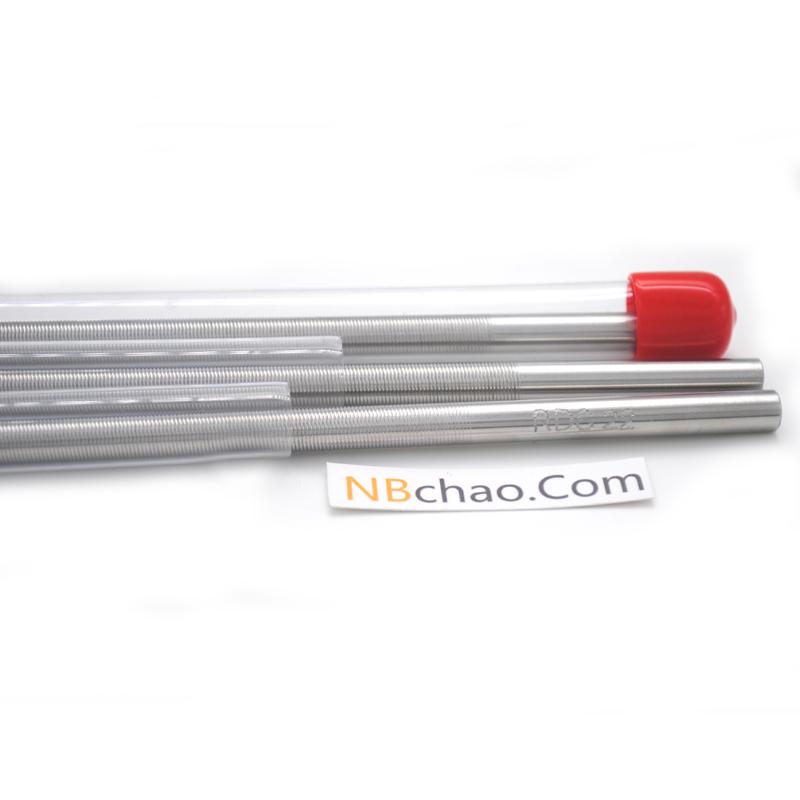

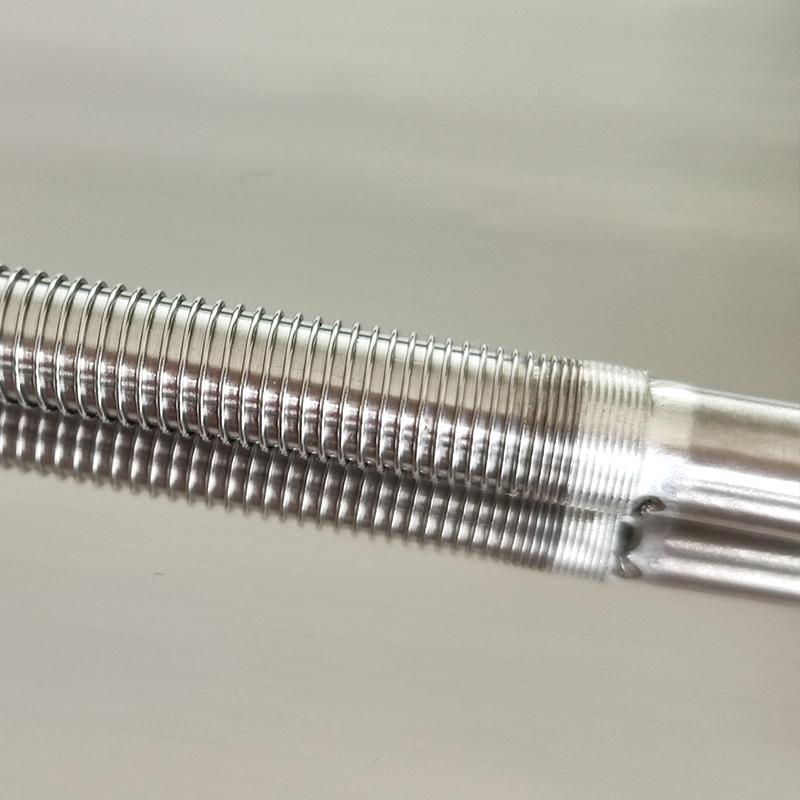

1. Wire-wound coating rod

Wirewound coating rods are the original "Meyer" rods, popularized by Charles Mayer in the 1920s and still widely used today. These coating rods feature wire wound and range in sizes from #3 to #75, including many half-sizes. The size of the rod is determined by the diameter of the wire (in mils, i.e., 0.001 inches).

Key features:

Customizable, wirewound coating rods can be removed and rewound to reduce cost and waste.There is no minimum order quantity.

Apply:Suitable for general coating applications with a focus on dimensional flexibility and cost-effectiveness.

2. Forming (groove) coating rod

Formed film coating rods, also known as groove coating rods, are rolled into solid steel rods and resemble wirewound coating rods in appearance. The size of the groove determines the thickness of the coating and is similar to the cavity in a wirewound coating rod.

Key features:

Easy to clean, the U-groove design reduces clogging and is easier to clean than wirewound coating rods.In high-volume production, molded coating rods are typically cheaper and have less variation in diameter.

Apply:Ideal for applications that require easy cleaning and cost-effectiveness.

3. Interstitial coating rod

Gap coating rods are designed for use with high viscosity coatings. These coating rods are characterized by small lines and spacing, resulting in wide, shallow cavities formed, which improve the flow of high-viscosity coatings.Spacing and smaller lines help reduce clogging and eliminate streaks in the coating.Gap coaters are less expensive but less durable than double-wound sticks.

Apply:Ideal for high-viscosity coatings that require improved flow and reduced clogging.

4. Double-wound coating rod

Double-wound coating rods are designed for high viscosity coatings and feature smaller wires wound around the top of larger wires. Such a design creates a wide and shallow cavity that improves the flow of the coating.

Key features: better flowability, durability

The double-wound design helps reduce clogging and ensures better wetting of the coating.It is more durable than interstitial coating rods, but it is also more expensive.

Apply:Ideal for high-viscosity coatings, where durability and clogging reduction are required.

Frequently Asked Questions

1. What are the advantages of forming a film coating rod?

The U-groove of the formed coating rod is easier to clean than the V-groove. In addition, the diameter of the molded coating rod varies little between different groove sizes and is less costly when produced in large quantities.

2. What is the effect of the diameter of the coating rod on the coating thickness?

The diameter of the coating rod does not affect the coating thickness. The thickness of the coating is determined by the size of the line or the size of the groove.

3. How to choose the right wire size?

Select a suitable starting point according to the size selection table, test it in the laboratory and measure the actual coating thickness. The selection is adjusted according to the actual transmission rate (line size to film thickness).

4. Does RDS offer sticks for my coater/puller?

RDS can supply Film Applicators for almost any coater or film puller. Just provide the make and model of the machine, and you can get a quote.

5. Should the applicator stick rotate when applying by hand?

The applicator rod should not be allowed to rotate during the coating process. The coating rod should be kept stable and the coating pulled down at a consistent speed and uniform pressure.

6. What is the difference in film thickness between wirewound and molded coating rods?

The V-shaped cavity of the wire-wound coating rod has different coating flow characteristics than the U-shaped groove of the formed coating rod. Therefore, the actual transmission rate is highly dependent on the rheological properties of the coating.

RDS Coating Rods offer a variety of solutions to meet the needs of different coating applications, each designed to meet specific viscosity, cost, and ease of use requirements. With its wide range of types and precise manufacturing processes, RDS coating rods provide an efficient and reliable solution for a wide range of coating applications. From the classic wire-wound rods to the new double-wound rods, each rod has its own special advantages and is able to meet different viscosity and coating requirements. By understanding the characteristics of different types of coating rods and their application scenarios, you can choose the right coating tool to achieve better coating preparation results. Whether in industrial production or laboratory research, RDS coating rods can help you increase productivity, reduce costs, and ensure consistency and quality of coatings. Choose the right RDS coating rod to make your coating preparation more accurate and efficient.