Importance of Terminal Section Analysis for Crimping Mass Detection of Automotive Wire Harness Terminals

As the neural network of the vehicle's electrical system, the quality of the automotive wiring harness is directly related to the safety and reliability of the vehicle. In the manufacturing process of automotive wiring harnesses, the crimping quality of the terminals is a key link. Substandard crimp quality can lead to poor contact, increased resistance, and even safety hazards. Therefore, as an efficient testing tool, the terminal section analyzer is widely used in the detection and analysis of the crimping quality of automotive wiring harness terminals to ensure the reliability and safety of electrical connections.

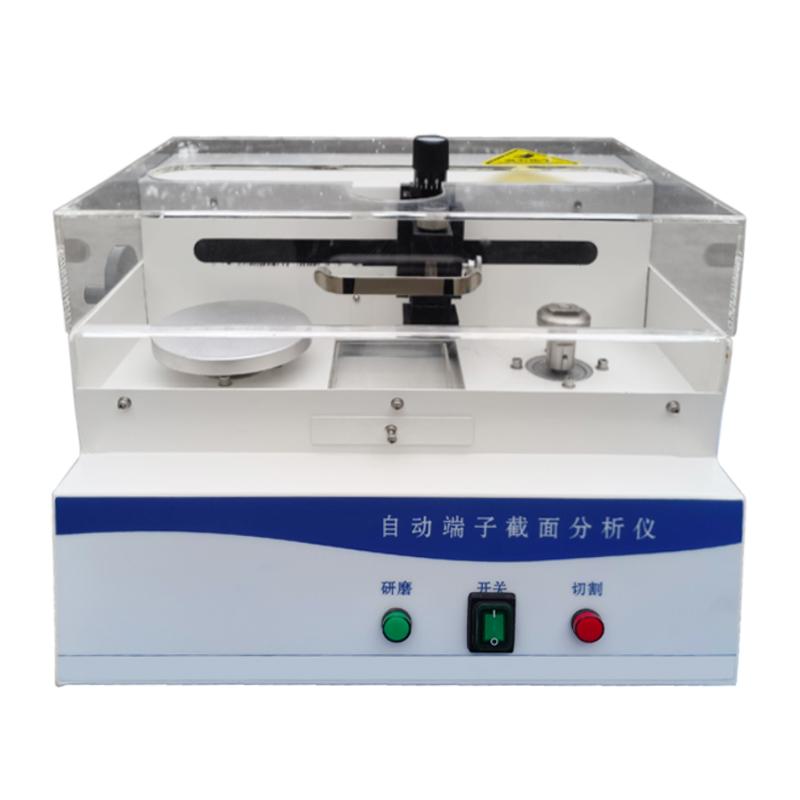

How the terminal section analyzer works

The terminal cross-section analyzer mainly evaluates the crimp quality by high-precision image acquisition and analysis of the cross-section of the terminal, and its working process generally includes the following steps.

1. Sample preparation - cut a section of the crimped terminal and fix it on the sample fixture to ensure that it is stable and does not move during the cutting process.

2. Cutting and polishing - use cutting equipment to cut the terminal into thin sheets, and then polish it to ensure that the section is smooth and free of scratches or bumps.

3. Image acquisition - shoot the terminal cross-section through a microscope and a high-resolution camera to obtain a clear cross-sectional image.

4. Image analysis - use professional software to analyze the image, including the crimping height, width, crimping depth, void, crack and other parameters of the terminal.

The importance of terminal cross-section analysis

Ensure the reliability of electrical connections

Terminal cross-section analysis accurately evaluates the crimp quality of the terminals, ensuring that each terminal has good contact properties after crimping. The quality of the crimp directly affects the reliability of the electrical connection, and a good crimp can ensure the smooth passage of current, reduce resistance and heat, and prolong the service life of the wiring harness.

Improve security

Poor crimping may cause the terminal to loosen or fall off during use, and in severe cases, it may cause electrical failure or even safety accidents such as fire. Through terminal cross-section analysis, problems in the crimping process can be found and corrected in time, thus greatly improving the safety of the vehicle.

Quality control and improvement

Terminal section analyzers can be used not only for quality inspection in the production process, but also as a tool for R&D and process improvement. By analyzing the crimping quality of terminals under different process parameters, the process flow can be optimized, the equipment settings can be improved, and the overall production quality can be improved.

As a high-precision and high-efficiency detection tool, the terminal section analyzer plays an important role in the crimping quality inspection of automotive wiring harness terminals. By performing a detailed analysis of the terminal cross-section, the reliability and safety of the electrical connection can be ensured and the overall quality of the product can be improved. In the future, with the continuous advancement of technology, terminal section analyzers will be used in more fields to help the quality improvement and innovative development of the manufacturing industry.