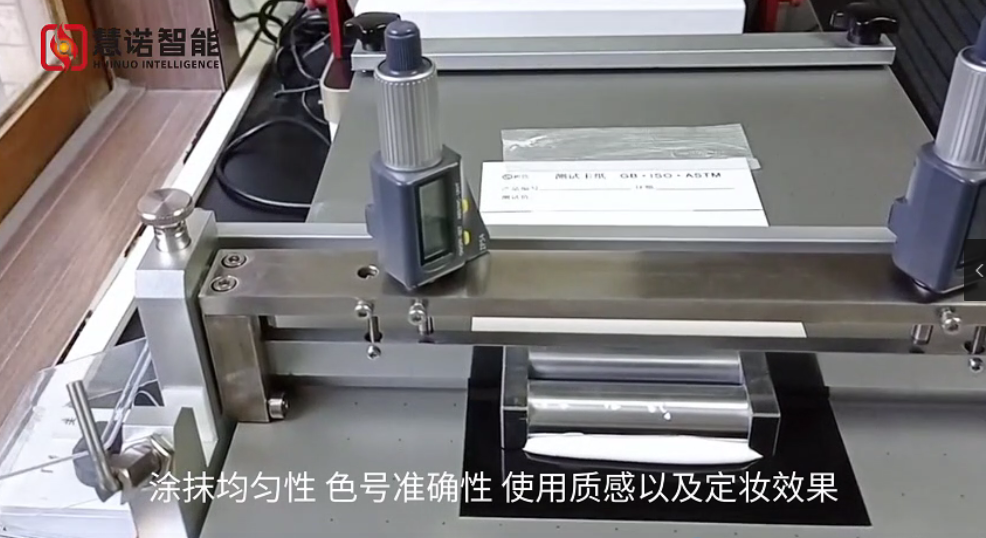

Application Case of Laboratory Film Applicator Applying Liquid Foundation on Cardboard [With Experimental Video]

Liquid foundations are an integral part of the cosmetics market, and their R&D and quality control processes have a crucial impact on the final outcome of a product. As a high-precision coating equipment, the laboratory coating machine plays an important role in the coating test of foundation liquid. This article will delve into the application of laboratory coaters to apply foundation on cardboard, including its specific applications and significance in formulation evaluation, uniformity testing, stability testing, sensory evaluation and quality control testing.

The basic principle and application background of the laboratory film coating machine

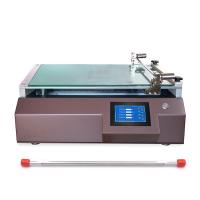

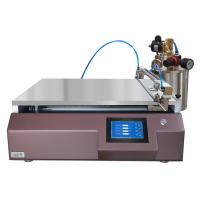

A laboratory film coater is a type of equipment that can precisely control the coating process, which is widely used in coatings, cosmetics, pharmaceuticals and food. During the development of liquid foundations, laboratory coaters provide uniform, controlled application results, ensuring reliable and repeatable test results.

The laboratory film coater uses a sophisticated mechanical device to evenly coat the liquid sample on the surface of the substrate. The core components of the coater include the applicator head, the conveyor system and the control system. Different types of coating heads can be selected according to needs, such as drum type, knife edge type and spray type, etc., to adapt to the coating requirements of different samples. The conveyor system is responsible for the smooth transfer of the substrate to the coating position, ensuring the continuity and stability of the coating process.

In the cosmetics industry, laboratory Film Applicators are mainly used for formulation development, product testing, and quality control. With the lab coater, the thickness and uniformity of the liquid foundation can be precisely controlled, so that its properties such as coverage, adhesion and skin feel can be more scientifically evaluated. In addition, the applicator can also be used to simulate real-world usage conditions to test the stability and durability of the foundation in different environments. The following is a video of Huinuo's experimental case.

Application of Laboratory Coating Machine in Formulation Evaluation

Formulation evaluation is a crucial part of the liquid foundation development process. With laboratory coaters, different formulations can be scientifically compared and evaluated to optimize product performance.

Coverage is one of the key properties of liquid foundation. With a laboratory coater, different formulations of foundation can be evenly applied to cardboard and the covering effect can be measured using equipment such as a Colorimeter. This not only quantifies the hiding power, but also removes the uncertainty of hand application, making the evaluation results more objective.

The uniformity of the liquid foundation directly affects its effectiveness and user experience. Laboratory coaters are able to precisely control the coating thickness to ensure that the sample is uniform and consistent every time it is coated, allowing for better evaluation of the uniformity of different formulations. This is essential for the development of a liquid foundation that feels good on the skin and visually appeals.

The adhesion of the liquid foundation determines its longevity and stability on the skin. By applying a sample of foundation to cardboard and performing various simulated tests such as wiping, rubbing, and washing, it is possible to evaluate the adhesion and durability of different formulations to optimize formulations and improve product performance.

Application of laboratory film coater in uniformity testing

Uniformity is an important indicator of the quality of a liquid foundation. The laboratory film coater can provide high-precision coating effect and provide a reliable technical means for uniformity testing.

Manual coating is not only time-consuming and labor-intensive, but also prone to human error, resulting in inconsistent test results. Laboratory coaters standardize sample coating through automation and precise control, ensuring uniformity and consistency for every test.

With a laboratory coater, a sample of the foundation can be evenly applied on cardboard and the uniformity and thickness distribution of the coating can be checked using a high-resolution microscope or image analysis software. These test results can help developers understand how different formulations perform in terms of uniformity, so that they can optimize the formulation and improve product quality.

An evenly applied liquid foundation provides a more natural and even finish, enhancing the user's experience. Uniformity testing by laboratory coaters can ensure the performance of the product in actual use, thereby improving user satisfaction and market competitiveness.

Application of laboratory film coater in stability experiments

Stability testing is an important test to ensure that the liquid foundation maintains stable performance under different environmental conditions. Laboratory film coaters have a wide range of applications in stability experiments.

With a laboratory coater, a sample of foundation can be applied to cardboard and subjected to different temperature, humidity and light conditions to observe how it changes. In this way, potential problems in the formulation can be detected in advance, ensuring the stability of the product under various environmental conditions.

Accelerated aging testing is a commonly used stability test method that accelerates the aging process of a sample by coating it with a laboratory coater and placing it under high temperature, high humidity or strong light conditions. This allows for an assessment of the long-term stability of the foundation in a shorter period of time, providing a scientific basis for the storage and shelf life of the product.

Laboratory applicators can also be used to assess the physical stability of liquid foundations, such as delamination, caking, and discoloration. By evenly coating the sample on the cardboard and subjecting to a series of physical tests, the stability of the product can be comprehensively evaluated, ensuring its stable quality during storage and use.

Application of laboratory film coater in sensory evaluation

Sensory evaluation is an important part of cosmetics research and development, which directly affects the market performance of products. Laboratory film coaters have an important application in sensory evaluation.

With a laboratory coater, a standardized sample of foundation can be applied to cardboard, eliminating errors in manual application. This makes the sensory evaluation more objective and unbiased, and helps to accurately evaluate the skin feel, color and coverage of the product.

Samples coated by laboratory coaters can be used for a variety of sensory evaluation methods, such as visual, tactile and odor evaluations. Through these methods, it is possible to fully understand the experience of using the product, so as to provide a basis for product optimization and marketing.

Sensory evaluation can intuitively reflect the user's acceptance and love of the product. Standardized samples provided by the laboratory coater allow for more accurate sensory evaluation, resulting in the development of liquid foundation products that are more in line with market needs and enhance product competitiveness.

Application of laboratory film coater in new technology and material testing

The development of new technologies and materials is the key to the innovation of liquid foundation products. Laboratory coaters have an important application in this process.

With laboratory coaters, it is possible to evaluate the coating properties of new materials, such as flow, adhesion and uniformity. This allows for the selection of materials with the best properties to support product innovation.

Laboratory coaters can also be used to test the effects of new technologies, such as nanotechnology and microcapsulation technology. Through the coating test, we can understand the application prospect of the new technology in the foundation liquid, and provide a scientific basis for product development.

Laboratory film coaters also play an important role in the testing of innovative products. Through coating testing, the performance and effect of innovative products can be comprehensively evaluated, data support can be provided for market promotion, and the market competitiveness of products can be improved.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research