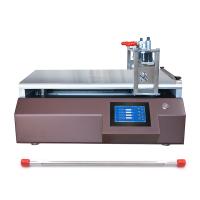

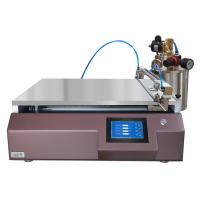

Bar & casting knife heating Film Applicator Application of Water Treatment Film on Non-woven Fabric

With the enhancement of environmental awareness and the progress of water treatment technology, non-woven fabrics have been widely used in the field of water treatment as an important filter material. Non-woven fabrics have the advantages of light weight, high strength, good air permeability and strong water absorption, and are widely used in the preparation of functional materials such as filtration, isolation and adsorption. However, pure non-woven materials are easy to be polluted and clogged during water treatment, so it is necessary to coat a layer of water treatment film on the surface of non-woven fabrics to improve their anti-pollution performance and filtration effect. As an efficient and precise coating equipment, the wire rod scraper heating coating machine can evenly coat the water treatment film on the surface of the non-woven fabric, thereby greatly improving the service life and treatment effect of the non-woven fabric. This article will discuss in detail the technical application of wire rod scraper heating film coating machine in non-woven water treatment film.

1. Application of non-woven fabrics in water treatment

Non-woven fabric is a kind of fiber network material formed by fibers through mechanical, thermal or chemical bonding, which is widely used in water treatment, medical and health, environmental protection, construction and other fields. In the water treatment process, non-woven fabrics are usually used as filter media, mainly used to filter impurities such as suspended solids, particles, and bacteria. However, a single non-woven material is easily clogged by impurities in long-term use, resulting in a decrease in filtration efficiency. Therefore, coating a layer of water treatment membrane with anti-fouling function on the surface of non-woven fabric is an effective way to improve its service life and filtration effect.

Second, the working principle and characteristics of the coating machine

In this application, a wire rod scraper is used to heat the film coating machine, which is a device that coats the surface of the substrate with a wire rod and a scraper. The working principle is to apply the paint evenly to the surface of the substrate by means of a wire rod or to adjust the scraper to control the thickness of the coating film, and the coating is cured or dried by a heating system. The main features of the wire rod scraper heating Film Applicator include:

The precise control of the wire rod and scraper makes the coating film thickness uniform, and the film thickness can be adjusted according to the requirements.

The heating system allows the coating to cure or dry quickly, increasing production efficiency and enhancing the adhesion and performance of the coating.

The equipment can be applied to various types of substrates, including non-woven fabrics, paper, metal films, etc., with a wide range of applications.

Modern wire rod scraper heating coaters are usually equipped with an automated control system, which can achieve precise coating operations, reduce manual errors, and improve production efficiency.

3. Characteristics of water treatment membrane and technical requirements for coating film

Water treatment membrane is a membrane material with special functions, which is mainly used to filter and purify pollutants in water. Common water treatment membrane materials include polymer membranes, inorganic membranes, and composite membranes. For non-woven coated water treatment films, the selection of coating materials and the control of coating process are particularly important.

Selection of membrane materials: Water treatment membrane materials should have good chemical resistance, pollution resistance, mechanical strength and hydrophilicity. Commonly used coating materials include polyvinylidene fluoride (PVDF), polyethersulfone (PES), polypropylene (PP), etc., which can form a dense film layer on the surface of non-woven fabrics through solution coating, melt coating and other processes.

Coating process requirements: During the coating process, it is necessary to control the viscosity, solid content, coating speed, heating temperature and coating thickness and other parameters of the coating to ensure the uniformity and performance of the film layer. Especially in the heating coating process, the heating temperature needs to be strictly controlled to prevent over-drying or thermal degradation of the film.

Fourth, the application of wire rod scraper heating film coating machine in non-woven coating water treatment film

In the process of coating the surface of the non-woven fabric, the wire rod scraper heating film coating machine mainly includes the following steps:

The first is the substrate pretreatment, before the coating operation, the non-woven substrate needs to be cleaned to remove surface impurities and oil stains to improve the adhesion of the coating film.Furthermore, according to the material of the non-woven fabric and the functional requirements of the water treatment film, the appropriate coating formula is selected, and the viscosity and solid content of the coating are adjusted to ensure that the coating is evenly distributed on the surface of the substrate.The paint is then evenly applied to the surface of the non-woven fabric by means of a wire rod, and the thickness of the film is adjusted by means of a scraper. In this process, the coating speed and rod pressure need to be controlled to obtain a uniform film layer.After coating, the film is dried or solidified by a heating system. The heating temperature needs to be adjusted according to the characteristics of the coating to ensure the adhesion and performance of the film.After the coating is completed, the thickness, uniformity, adhesion and contamination resistance of the film layer are tested to ensure that the quality and performance of the water treatment membrane meet the requirements.

5. Application examples and technical analysis

In order to better understand the application of wire rod scraper heating film coating machine in non-woven coating water treatment film, we can analyze several practical application examples.

1. Coating of polyvinylidene fluoride (PVDF) film

PVDF membranes are often used in water treatment due to their excellent chemical resistance and pollution resistance. When coating PVDF films on the surface of nonwovens, appropriate solvents and viscosity modifiers need to be selected to ensure the fluidity and uniformity of the coating. Through the wire rod coating and scraper adjustment, the final layer is formed into a uniform and dense film. In the process of heating and drying, the temperature needs to be strictly controlled to prevent the thermal degradation of PVDF.

2. Coating of polyethersulfone (PES) film

PES membranes have excellent high temperature and chemical resistance, and are often used in high temperature water treatment systems. When applying PES film, a high-temperature heating system is used to accelerate the curing of the coating. With precise scraper control, the right film thickness and uniformity can be obtained, ensuring the long-term stability of the PES film during water treatment.

3. Coating of composite film

Composite membranes are usually composed of multiple layers of different materials and have versatile water treatment properties. When applying a composite film to the surface of a nonwoven, it is necessary to apply different coatings in multiple times, and the thickness of each film is precisely controlled by means of wire rods and scrapers. The heating and drying process needs to be temperature adjusted according to the characteristics of different materials to ensure good adhesion and overall performance between the laminate layers.

6. Technical difficulties and solutions

In the process of coating water treatment film on non-woven fabrics, there are mainly the following technical difficulties:

The surface structure of non-woven fabric is complex, which can easily lead to uneven coating film. Solutions include selecting the right wire rod and blade, as well as adjusting the coating speed and pressure to ensure a uniform coating film.

The coated water treatment film needs to have good adhesion to the non-woven substrate to prevent the film from peeling off or peeling off. Adhesion can be improved through substrate surface treatment and selection of appropriate coating formulations.

During the heating process, too high a temperature may cause thermal degradation of the film, while too low a temperature may result in insufficient curing of the coating. Therefore, the temperature control accuracy of the heating system is crucial for the quality of the coating film.

Therefore, coating water treatment film on non-woven fabrics is generally usedWire rod scraper heating film coating machine,It can improve the filtration effect and service life of non-woven fabrics. By precisely controlling the coating process parameters and selecting the right coating, the machine is able to form a uniform, dense and well-adhesive water treatment film layer on the surface of the nonwoven.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Drawdown blade Film Applicator Coating UV glue on film

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research