Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

background

In modern industrial production, the application of automation equipment has greatly improved production efficiency and product quality, especially in the field of coating film, automatic coating machine has become an important equipment in coating operations because of its high precision, stability and repeatability. The experiment of automatic film coater coating RTV (room temperature vulcanization) silicone glue on aluminum sheets is of great significance, because RTV silicone glue is widely used in electronic device sealing, automotive parts bonding, and protective coatings in the aerospace industry.

In these applications, coating uniformity, adhesion, and thickness control are key technical indicators. Therefore, the purpose of this experiment was to investigate the technical feasibility and performance of the automatic film coater for coating RTV silicone glue on aluminum plates.

Experimental equipment and materials

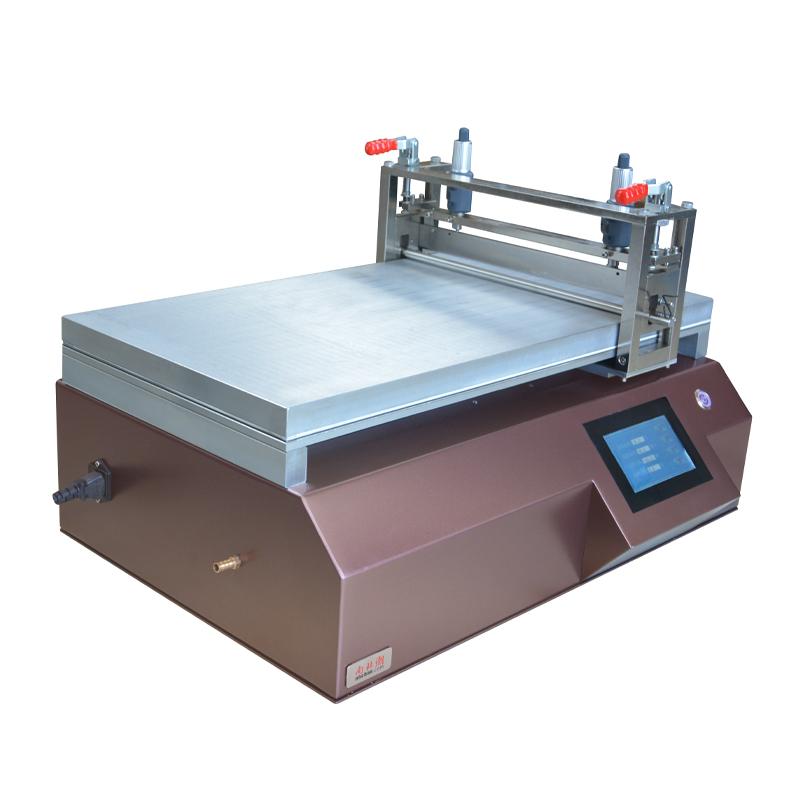

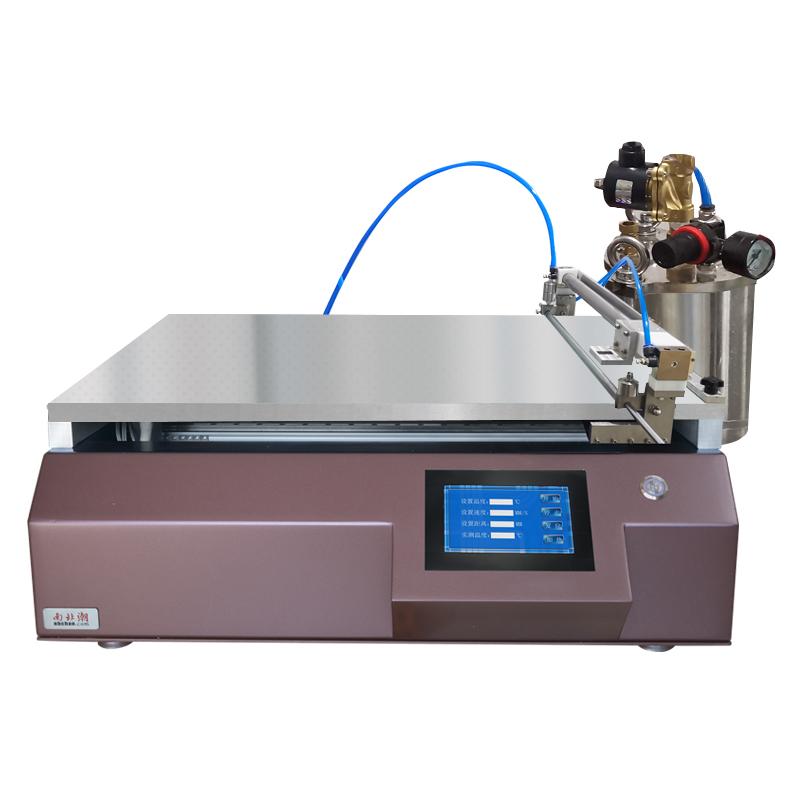

The main equipment used in this experiment is the automatic coating machine, which is equipped with a high-precision coating head, an intelligent control system and a precision transmission mechanism. The automatic film coater has adjustable coating speed, coating thickness and coating method, which can adapt to the coating material with different viscosity and characteristics.

Aluminum plate: The size is 100mm×100mm×2mm, and the surface is pickled and passivated to ensure that the surface is clean and has a certain roughness.

RTV Silicone Glue: A low-viscosity room-temperature vulcanized silicone with good adhesion, weather resistance and electrical insulation, suitable for coating on various substrate surfaces.

Experimental Methods

Aluminum plate treatment——The aluminum sheet is first subjected to surface pretreatment, including degreasing, pickling, passivation, and drying, to remove surface impurities and increase the adhesion of the coating. The surface of the pre-treated aluminum sheet should be free of oil, water stains and other contaminants.

Preparation of RTV Silicone Glue - According to the ratio of the product instructions, mix the RTV Silicone Glue and the curing agent evenly, stir until there are no bubbles and mix evenly. Let the mixed glue sit for 5-10 minutes to ensure that the internal air bubbles are fully released.

Parameter setting of automatic film coating machine:

According to the viscosity of RTV silicone glue and the coating requirements of aluminum plate, the coating speed of the coating machine is set to 50mm/s.

The coating thickness is set to 0.2mm to ensure the uniformity and stability of the coating.

Scraper coating is used to ensure that the RTV silicone glue is evenly distributed on the surface of the aluminum plate.

The treated aluminum plate is fixed on the workbench of the film coating machine, and the film coating machine is started for the coating operation of RTV silicone glue. During the coating process, the operating status of the coating head and the change of coating thickness are monitored in real time to ensure that the coating is uniform and stable.

After the coating is completed, the aluminum plate is placed at room temperature to cure naturally for 24 hours to ensure that the RTV silicone glue is completely vulcanized. During the vulcanization process, the aluminum sheet is protected from mechanical stress or temperature changes to prevent cracks or peeling of the coating.

Performance testing

In order to evaluate the performance of RTV silicone glue coating on aluminum plates, the following tests were performed in this experiment:

Coating thickness measurement: A laser Thickness Gauge is used to measure the thickness of the surface of the coated aluminum sheet. The measurement results show that the coating thickness is uniform, and the error is controlled within ±5μm, which meets the expected requirements.

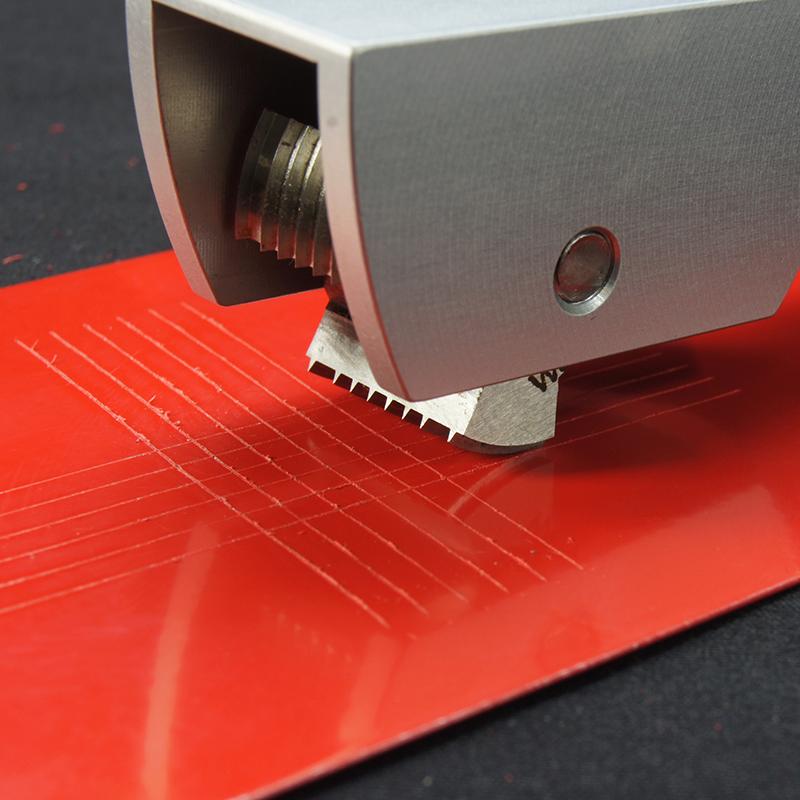

Coating adhesion test: The adhesion of the coating is tested by the scribing method. Draw a certain size lattice on the surface of the aluminum plate, paste it with 3M tape and quickly tear it off, and observe the peeling off of the coating. The test results show that the adhesion of the coating is good, and there is no obvious falling off, which meets the first-class adhesion standard.

Weather resistance test: The coated aluminum plate is placed in a high temperature and high humidity environment for accelerated aging test. The test conditions were 85°C, relative humidity 85%, and the duration was 100 hours. After the test, there are no bubbles and cracks on the surface of the coating, and the performance remains stable.

Corrosion resistance test: The coated aluminum plate was immersed in 3.5% NaCl solution for 72 hours of corrosion test. The test results show that the coating has no corrosion spots and good protection performance.

Electrical insulation performance test: The electrical insulation performance of the coating is tested by using a high-voltage insulation resistance Tester. The test voltage is 1000V, and the results show that the insulation resistance value of the coating is greater than 10^12Ω, which meets the requirements of electronic device packaging.

Analysis of key technical requirements

In the automatic coating experiment of RTV silica gel glue, the key technical requirements of the automatic film coating machine are mainly reflected in the following aspects:

Coating uniformity – The automatic coating machine should have high-precision coating control to achieve uniform coating distribution on the surface of the aluminum sheet. Through the precise coating head design and advanced control system, the coating machine can effectively reduce the unevenness of coating thickness and ensure product quality.

Coating thickness control——Precise control of coating thickness is a key factor in guaranteeing coating performance. The automatic coating machine should be equipped with a high-precision thickness adjustment device, which can flexibly adjust the coating thickness according to the characteristics of different coating materials and experimental requirements. At the same time, through the real-time monitoring and feedback mechanism, the parameters can be automatically adjusted during the coating process to ensure the stability of the coating thickness.

Selection of coating method——According to the rheological properties of RTV silica gel glue, choosing the appropriate coating method is a prerequisite for achieving high-quality coatings. The drawdown blade coating method is suitable for low to medium viscosity glue materials and can achieve uniform coating results at low coating speeds. For highly viscous coating materials, it may be necessary to choose a spray or roller coating method to improve coating efficiency and coating quality.

Material suitability——The design of the automatic film coater should fully consider the characteristics of the coating material, such as viscosity, solid content and curing method. By optimizing the coating head, scraper angle and transmission mechanism of the Film Applicator, the adaptability of the equipment to different materials can be improved, and the adhesion and uniformity of the coating on various substrates can be ensured.

Device stability and repeatability——The stability and repeatability of the automatic film coater directly affect the consistency of the coating and the reliability of the experimental results. The transmission mechanism of the equipment should have high precision and high stability to avoid jitter or deviation during the coating process. At the same time, the control system of the coater should have good repeatability to ensure consistent results from application to coating.

conclusion

Through the study of this experiment, it can be seen that the application of RTV silicone glue coating on aluminum plate by automatic film coating machine has good technical feasibility and excellent performance. The coating thickness is uniform, the adhesion is strong, and the weatherability, corrosion resistance and electrical insulation properties meet the requirements of industrial applications. In the process of the experiment, the technical requirements of the coating machine, such as coating uniformity, coating thickness control, coating method selection and intelligent control system, played a key role in the experimental results.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research