Application Case of Experimental Scraping Machine Coating Polymer on Non-woven Fabric [Video Demonstration]

As a new type of nonwoven, non-woven fabrics are more and more widely used in medical, environmental protection, construction and packaging fields. In order to improve the performance of nonwovens, it is often necessary to coat various polymer materials on their surfaces. In this process, the experimental squeegee coater plays an important role.

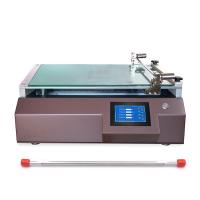

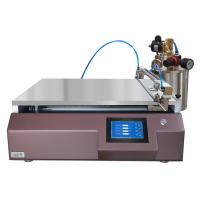

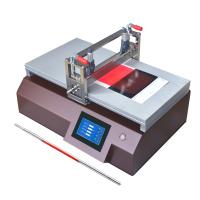

The experimental squeegee coater is a kind of equipment used to coat uniform films on different substrates, which is widely used in experimental research in the fields of materials science, chemical engineering, electronics and medicine. According to the different coating methods, the experimental squeegee coater can be divided into types such as wire rod coater, scraper coater, dip coater and spraying machine. In this case, the adjustable wet film preparer is used for scraping, and the adjustable scraper is pushed to scrape the film with a Huinuo automatic scraper with vacuum adsorption function.

Non-woven fabrics are fabrics made by combining fibers with each other by physical or chemical methods. Key properties include fiber structure, porosity, and surface tension, which affect the coating uniformity and adhesion of polymers. For example, nonwovens have irregular fiber arrangement, which can lead to uneven distribution of polymers during the coating process. The high porosity of nonwovens can also affect the permeability of polymers, so when applying polymers, these properties need to be carefully analyzed and the coating process adjusted accordingly.

Here's how it workedThe operation video can observe the operation details and steps of the technology:

The formulation of the polymer solution is a critical step in the coating process. The viscosity, concentration and dispersion of the solution directly affect the uniformity and adhesion of the coating. In general, the coating effect is optimized by selecting the appropriate solvent and adjusting the polymer concentration. In addition, the coating speed and coating thickness are also important parameters. Applying too high or too low a coating speed can cause uneven coating. The control of the coating thickness depends on the requirements of the specific application. Drying and curing after coating is a critical step in ensuring the quality of the coating, and different polymers require different drying and curing conditions, such as temperature, humidity, and time. Proper temperature settings can help improve coating results and increase productivity.

Non-woven coated polymers are mainly common in several fields: first, in the medical field, non-woven fabrics are often used to make disposable medical masks and surgical gowns. By coating nonwovens with antimicrobial or water-repellent polymers, their protective properties can be significantly improved. For example, the application of antimicrobial polymers can effectively inhibit the spread of bacteria, while the application of waterproof polymers can enhance the waterproof performance of masks.Second, in the field of construction, non-woven fabrics are mainly used to make sound insulation and thermal insulation materials. Coated polymers can improve the water and corrosion resistance of these materials, thereby improving their service life and performance. Third, in the field of packaging, non-woven coated polymers can be used to make moisture-proof and oil-proof packaging materials, such as the moisture-proof layer in food packaging can effectively extend the shelf life of food. Fourth, in the field of environmental protection, non-woven fabrics are used to make filter materials. Coated with high-efficiency filtration polymers can improve its filtration efficiency, which is widely used in air and water purification.

The technical application of experimental squeegee coater to coat polymers on non-woven fabrics has a wide range of prospects and practical significance. By selecting the right equipment and optimizing the process parameters, the performance of nonwovens can be significantly improved to meet the application needs of different fields.

- 1Scraping machine selection case: film substrate large size high accuracy scraping solution

- 2Application and Optimization Technology of Automatic Draw-Down Applicator in Preparative Polyester Film

- 3Three Methods of Preparative Unsupported Adhesive Film on Plastic Plate

- 4Application of Lab Coating Scraper Machine on Nonwoven Fabric

- 5Laboratory film coating machine case | Automatic scraping and gluing on sponge 2mm