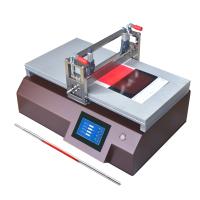

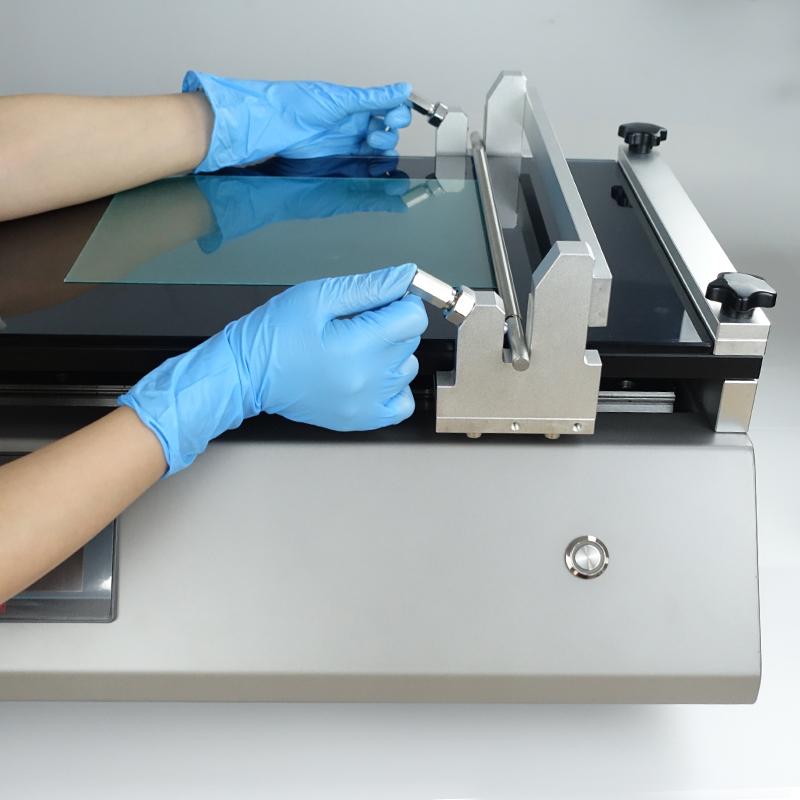

Experimental coater application case video of liquid silica gel on release paper

In modern industrial and scientific research experiments, the application of experimental coater coating liquid silica gel on release liner has received extensive attention. As a material used to prevent adhesion and separation, release liner is widely used in the production of various adhesives, labels, tapes and medical supplies due to its unique surface properties and good stability. Liquid silicone, on the other hand, performs well in many fields due to its good flexibility, transparency, high temperature resistance and waterproof properties. In this context, the application of the experimental coater is particularly important, as it is able to evenly coat the liquid silicone on the release liner, thereby improving the overall performance and quality stability of the product.

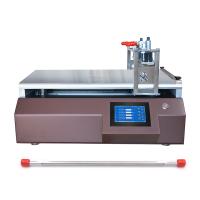

As a high-precision equipment, the experimental coater is specially used to coat different types of materials, such as liquids, adhesives, coatings, etc., on various substrates. For the application of liquid silicone coating on release liners, the core purpose is to ensure that the thickness of the coated liquid silicone layer is uniform, the surface is smooth, and the adhesion properties meet the expected requirements. This process requires not only the coating accuracy and stability of the equipment itself, but also the rheology, viscosity, curing conditions and characteristics of the release liner of the liquid silica gel. Therefore, the selection and operation of the experimental coater in this type of application is particularly critical.

1. Material properties and interaction between release liner and liquid silicone

As the substrate for coating liquid silicone, the material properties of the release paper play a crucial role in the coating effect. The release liner is generally composed of two parts: paper base and coating, and the coating is mostly silicone oil or fluoride to ensure that its surface is smooth and flat, and has good demoulding performance. The type and quality of the release liner directly affects the adhesion of the liquid silicone and the final curing effect. Therefore, in the experimental coating process, it is necessary to select the appropriate release paper according to the characteristics of the liquid silicone to ensure that it is not prone to wrinkles, deformation and breakage, and can be evenly coated with the liquid silicone.

Liquid silica gel is a silicone material based on siloxane, which has excellent flexibility, high temperature resistance, aging resistance and good electrical insulation properties. The rheology and viscosity of this material are critical for the stability of the coating process and the quality of the coating. When the release liner is applied on the experimental coater, the rheology of the liquid silica gel determines its expansion and flow behavior on the release liner surface. Viscosity, on the other hand, affects the control and uniformity of its coating thickness. Therefore, in practice, it is often necessary to optimize the coating effect of liquid silica gel on the release liner by adjusting the viscosity of the liquid silica gel, adding additives or adjusting the coating parameters.

Second, the selection and application scenarios of the experimental coating machine

In the experiment of coating liquid silica gel on release paper, the selection of the experimental coater directly affects the accuracy and repeatability of the experimental results. First of all, according to the requirements and expected results of the experiment, the experimental coater needs to have high-precision coating control ability, which can accurately control the coating amount and coating speed. At the same time, the operational stability and repeatability of the equipment are also key factors, requiring it to maintain a stable coating state during long-term operation without offsetting or uneven coating. In addition, the experimental coater needs to be versatile enough to be able to adapt to the needs of different types of release liners and liquid silicone.

Depending on the purpose of the experiment and the coating requirements of the liquid silicone, choosing the appropriate coating method is also an important consideration. Common experimental coaters include roller coaters, scraper coaters and spraying machines, and different types of coaters have their own characteristics in terms of accuracy, coating thickness control and applicable materials. For example, squeegee coaters are often used in applications where a high coating thickness is required, and can be finely adjusted by a mechanical squeegee to achieve precise control of the coating thickness. The roller coater, on the other hand, is more suitable for large-area continuous coating, and is suitable for the uniform distribution of liquid silicone on the release liner. Choosing the right type of experimental coater can effectively improve the coating efficiency and coating quality.

3. Control of key technical parameters in the experimental coating process

In the process of liquid silica gel coating experiment on the experimental coating machine, the control of parameters is the key to ensure the success of the experiment. Coating speed is a very important parameter, which directly affects the coating thickness and uniformity of liquid silicone on the release liner. Excessive coating speed may lead to uneven coating, defects such as bubbles or streaks; Applying too low a speed can result in too much coating, resulting in waste or too thick a coating. Therefore, it is necessary to select the appropriate coating speed according to the viscosity of the liquid silica gel, the characteristics of the release liner and the experimental requirements.

The control of coating thickness is also one of the key aspects in experimental coating. The thickness of the liquid silicone on the release liner not only affects its mechanical properties after curing, but also affects the transparency and surface flatness of the coating. In order to achieve the desired thickness, it is often necessary to perform several adjustments on the coater to achieve precise thickness control by adjusting the blade height, roll compression strength or spray volume, for example. In addition, in practice, it is also necessary to pay attention to the changes in ambient temperature and humidity, which can affect the rheology and coating effect of liquid silica gel.

Fourth, the curing process of liquid silica gel after coating on the release liner

After the liquid silicone has been coated, the choice of curing process also has a significant impact on the quality of the final product. There are two main curing methods for liquid silica gel: room temperature curing and heat curing. Room temperature curing is usually suitable for applications where production efficiency is not high or the material is more sensitive to temperature, while thermal curing is more suitable for industrial mass production, where it cures quickly and can significantly improve production efficiency.

During the experimental coating process, the curing temperature and time of the liquid silica gel need to be optimized according to the material properties and coating requirements. In general, the higher the curing temperature, the faster the curing speed, but it also has an impact on the internal structure and properties of the coating. For example, excessively high temperatures can cause uneven shrinkage of the coating and stress concentrations, which can affect release performance and durability. Therefore, reasonable selection of curing conditions to ensure uniform curing of the coating without internal stress concentration is the key to improving product quality.

The following is a practical case video of Nanbeichao Technology applying silicone to the release liner:

5. Advantages of experimental coating machine in liquid silicone coating application

The advantages of the experimental coater in liquid silicone coating applications are mainly reflected in its high precision and high stability. First of all, the experimental coater can accurately control the parameters of the coating process, such as coating speed, coating thickness, coating amount, etc., so as to ensure the uniform coating of liquid silicone on the release liner. This high-precision control capability can significantly improve the quality of the coating, reduce the rate of defective products, and meet the needs of different production and experiments.

Secondly, the experimental coating machine is easy to operate and has a high degree of automation. The modern experimental coating machine is equipped with an intelligent control system, which can automatically control the coating process according to the preset program, reduce manual intervention, reduce the difficulty of operation and the probability of error. At the same time, the stability and reliability of the equipment enable it to run for a long time without failure, further improving production efficiency and product quality.

Finally, the versatility and flexibility of the experimental coater makes it widely adaptable in different coating scenarios. Whether for small batch laboratory research or large-scale industrial production, the experimental coater can provide precise coating solutions to meet the coating needs of different thicknesses, different materials, and different applications. This wide range of applicability makes the experimental coater an indispensable piece of equipment for liquid silicone coating applications.

6. Practical application cases of liquid silicone coating on release paper

In practical applications, liquid silicone coated on release liners is mainly used to produce products such as self-adhesive labels, waterproof seals, and medical supplies. For example, in the medical field, liquid silicone is widely used in the manufacture of anti-adhesion coatings for urinary catheters, infusion tubes, surgical gloves and other instruments, and its excellent biocompatibility and durability can ensure the safety and longevity of the instruments. In this process, the experimental coater can precisely control the coating thickness and uniformity of the liquid silica gel, so as to ensure the stability and consistency of product quality.

Similarly, in the production of self-adhesive labels and tapes, liquid silicone is an anti-stick material that can effectively prevent the adhesion between labels and tapes, ensuring smooth and convenient use. Through precise coating control, the experimental coater can achieve uniform distribution of liquid silicone on the release liner, prevent defects such as uneven coating or bubbles, and improve the appearance quality and user experience of the product.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Experimental application of water-based paints on film laminating paper by laboratory coater

- 5Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 6Application of small coater in gel coating

- 7Application of small coater in polyimide slurry

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Method and application of experimental coater coating water-based slurry on aluminum foil