Paper and Cardboard Determination of water-absorption

In this paper, a method for determining the water absorption of paper and cardboard (Coboff method) is presented. This method evaluates the surface water absorption performance of a specimen by measuring the amount of water absorbed by it at standard temperature and pressure. Specific instruments and reagents are used during the experiment, ensuring that the test is performed under standardized conditions for accurate results. Key steps include specimen preparation, water absorption testing, and calculation of results.

introduction

Background and significance

Paper and cardboard are widely used in packaging, printing, and other industrial fields, and their water absorption directly affects the quality and performance of products. Therefore, understanding and measuring the water absorption of materials is of great significance for process optimization and quality control.

The importance of water absorption to the properties of paper and cardboard

Water absorption affects the strength, durability and printing effect of the paper. Controlling water absorption increases product life and customer satisfaction.

definition

Water absorption refers to the amount of water absorbed by paper and cardboard per unit area under a specified pressure and temperature after a certain period of time, usually measured in grams per square meter (g/m²).

The unit of measurement is g/m², and the test needs to be performed in a standard environment of 23±1°C to ensure the accuracy and comparability of the data.

principle

Before the start of the experiment, the mass of the paper sample is weighed, then one side of the sample is in contact with the water, the surface moisture is absorbed after a set time has passed, and finally weighed to obtain the water absorption.

The amount of water absorbed is calculated by measuring the difference between the mass of the sample after it has been absorbed and the mass before it has been absorbed.

Instruments and reagents

Specifications and requirements of the erection Tester

The size and material of the cylinder - the inner diameter of the metal cylinder is 112.8±0.2mm, the height is 50mm, and the inner surface is smooth.

Leak-proof design – The cylindrical lid should be made of a flexible and non-absorbent material to prevent water leakage.

Water quality requirements for use – Distilled water or detached water should be used to ensure the reliability of test results.

Requirements for water suction devices

The specification of absorbent paper - the quantitative amount should be 200~250g/m², and the absorption height should be 75mm/10min.

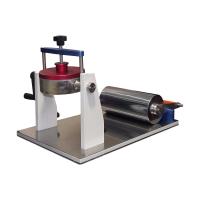

The standard for smooth metal flat rolls – roll width 200±0.5mm, mass 10±0.5kg.

Other lab equipment – including a precision balance capable of measuring down to 0.001g, a stopwatch with accurate readings, and a 100ml glass graduated cylinder.

Test preparation

Specimen sampling is carried out in accordance with relevant standards to ensure representativeness.

Treated under defined temperature and humidity conditions to eliminate environmental impacts.

Cut into 125mm×125mm or 125mm diameter round specimens, and prepare 10 sheets (5 on the front and 5 on the back).

Test Steps

Use a 100ml glass measuring cylinder to accurately measure distilled water and pour it into the metal cylinder of the test instrument.

Place the weighed specimen in the cylinder, make sure the face to be measured is facing the water, and then cover the specimen gland for fixation.

Flip the cylinder 180° to start the timer to ensure that contact is maintained for the specified time.

After removing the specimen, press it using a smooth metal flat roller, taking care that the sample absorbs water downwards and weigh it quickly to avoid water evaporation.

Each specimen can only be used once, and if there is still excess moisture on the surface after water absorption, the specimen should be discarded. If it exceeds 20%, the test time should be shortened.

Calculation of test results

The amount of water absorbed is determined by the difference between the quality of the specimen after water absorption and the mass of the sample before water absorption, expressed in units g/m².

Calculations need to be accurate to one decimal place to ensure data reliability and comparability.

conclusion

Analyze the importance of water absorption test results in the performance evaluation of paper and cardboard, and discuss their practical applications in quality control and material development.

It is recommended to further study the water absorption characteristics of different paper materials and explore improved test methods to improve the accuracy and efficiency of measurements.

summary

The Kobs method is a reliable method for testing the water absorption of paper and cardboard for quality control and performance evaluation of materials. Through rigorous experimental procedures and standardized operating procedures, the water absorption of materials can be accurately measured, helping to optimize material properties in production and R&D processes. In practice, specimen selection and environmental conditions are critical to ensure the accuracy and repeatability of test results.