Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

The coating of small workpieces on ceramic substrates is used in a wide range of applications, especially in the field of electronics and sensors. Ceramic substrates are often used in the manufacture of high-precision components such as capacitors, sensors, semiconductors, and electronic packaging due to their high temperature resistance, insulation, and chemical stability. In these applications, the coating process is used to coat a ceramic substrate with a functional material such as a conductive paste, insulating layer, or protective coating to improve the electrical properties, abrasion resistance, or corrosion resistance of the component. For example, in the manufacturing process of film capacitors, it is necessary to evenly coat the ceramic substrate with a dielectric material to ensure its stable electrical properties. In the field of sensors, coating technology is relied on to achieve precise coating of sensitive layers, thereby improving detection sensitivity and stability. By coating small workpieces on ceramic substrates, their functional properties can be significantly improved to meet the stringent material and performance requirements of various high-precision electronic products.

When coating a small area of workpiece, the technical difficulties are mainly reflected in the uniformity and precision control of the coating. Due to the small area of the workpiece, edge effects can easily occur during the coating process, resulting in the coating being too thick or too thin at the edges, affecting the overall quality. In addition, coating equipment requires extremely high precision to apply stably in tight areas while avoiding defects such as film breakage and air bubbles. Another challenge is the control of material waste, especially when working with high-value materials, where the amount of slurry used must be precisely controlled to prevent excess or under-use. In addition, the setup and commissioning of coating equipment is more complex, requiring careful adjustments to the characteristics of the workpiece and material to ensure consistent quality every application. These difficulties make the process of coating a small area of workpiece require not only excellent equipment technology, but also rich experience and fine process control ability of the operator.

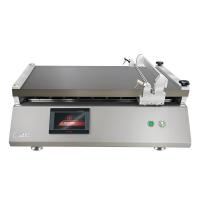

This experiment is an experimental case of Huinuo wire rod coating machine coating film on the ceramic substrate of small workpiece, using high-precision wire rod coating to achieve higher precision and more uniform coating film. In this experiment, it is still difficult to control the uniformity and accuracy of the coating film. Let's take a look at how professional technology can be used to coat the film with Huinuo coating machines.

From the final coating effect, it is very uniform and flat. Pay attention to the control of the coating amount and coating speed in the coating process, and the requirements for the flatness of the coating platform and the smoothness of the coating for the small workpiece coating film are also relatively high.

![Application case of wire rod coating machine coating material on ceramic substrate of small workpiece [experimental video demonstration] with Figure 1](http://img.nbchao.com/upload/editor/image/20241022/1729567569576026341.png)

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of laboratory coater coating aluminum oxide paste on PET film

- 6Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 7Method and application of experimental coater coating water-based slurry on aluminum foil

- 8Application of wire rod coater in hydrogen battery separator prepative

- 9Technical introduction of hot-melt adhesive coater