Detection Error Analysis of Force Lever calibrated Tensile machine

Regarding the analysis of the detection error of the force-measuring lever calibration Tensile Testing Machine, the standard force-measuring lever has the advantages of high precision, wide measurement range, portability and simple structure in practical practical applications. Therefore, in the application of tensile test calibration less than 5kN, it is the preferred standard testing instrument. However, in the daily application of levers, due to the influence of many factors, there will also be measurement errors. This article evaluates and analyzes the measurement uncertainty, as follows.

1 Measurement method

According to JJG475-2008 "Verification Regulations for Electronic Multifunctional Testing Machines", the force value calibration of EMT-2000A 0.5 electronic Tensile Testing Machine is carried out by using the force measuring lever as the standard instrument.

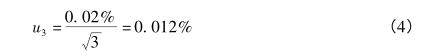

Calibration of the force measuring lever The actual state of the Tensile Testing Machine is shown in Figure 1. Based on the systematic theoretical analysis of the characteristics of the standard force measuring lever, the verticality of the force axis after the force point of the lever is connected to the lower connector of the Tensile Testing Machine, the lever scale The mass error of the body level and the matching weight of the lever is the additional uncertainty component introduced by the standard instrument of the force-measuring lever in the process of calibrating the Tensile Testing Machine, as follows:

(1) Relative uncertainty u 1 introduced by leverage level;

(2) The relative uncertainty u 2 introduced by the perpendicularity of the force axis at the end of the lever force point;

(3) The relative uncertainty u 3 introduced by the indication error of the supporting weight of the lever;

(4) Relative uncertainty u 4 introduced by measurement repeatability;

(5) Uncertainty u 5 introduced by the resolution of the calibration Tensile Testing Machine.

4 Calculation of Uncertainty Components

4.1 Relative uncertainty u introduced by lever levelness 1 Theoretical calculations and practical tests show that if the lever levelness is controlled within 0.05%, the error introduced by the horizontal angle is ±0.03%, with a uniform distribution estimate:

4.2 The relative uncertainty u2 introduced by the perpendicularity of the force axis of the lever force point. Theoretical calculations and practical tests show that when the lever is in a horizontal state, if the consistency error between the eccentric distance of the lower connector of the lever and the length of the short arm of the lever is controlled within ± Within 2%, the inclination angle of the lever fulcrum end is controlled within ±0.5°, then the error introduced by the vertical angle is ±0.05%, estimated by uniform distribution:

4.3 The relative uncertainty u introduced by the indication error of the matching weight of the lever. 3 According to the requirements of JJG808-2014 "Standard Force Measuring Lever Verification Regulations", the allowable error of the weight of the supporting force value of the lever is ±0.02%. Uniform distribution estimate:

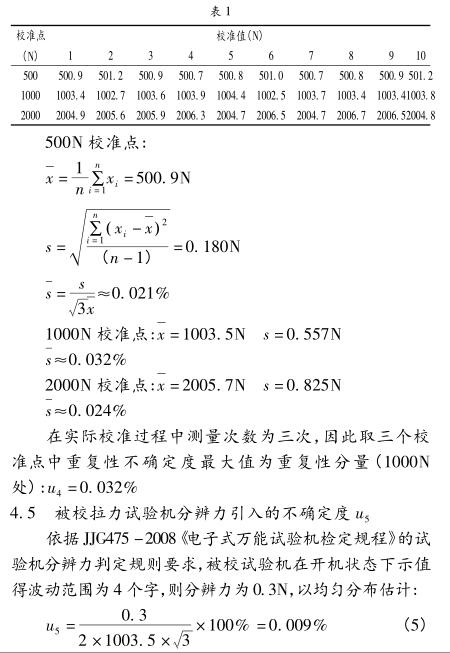

4.4 Relative uncertainty u introduced by measurement repeatability 4Take the EMT-2000A electronic Tensile Testing Machine as an example, under repeatability conditions, use the force measuring lever to continuously and repeatedly measure the indication points of 500N, 1000N and 2000N respectively 10 times, the corresponding measurement results are shown in Table 1:

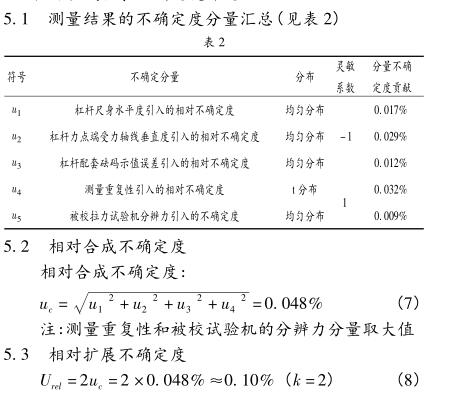

5 Evaluation of relative composite expanded uncertainty

6 Conclusion

Through the analysis of the measurement process of the force measuring lever calibration Tensile Testing Machine, it can be seen that the verification or calibration of the 0.5 level electronic Tensile Testing Machine can be satisfied by using the 0.1 level standard force measuring lever. In the process of calibration, as long as the horizontality of the lever and the verticality of the force axis of the force point end of the lever are effectively controlled, the accuracy and reliability of the calibration result can be guaranteed.

- 1Tensile machine application in various industries

- 2Technical analysis of key parameters of Tensile machine: Scientific selection from force measurement accuracy to Power system

- 3Tensile machine purchasing guide [dry version]

- 4Talking about the performance test of epoxy resin film coated on PET

- 5ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 6Common problems and solutions in tensile testing

- 7What is tensile strength testing and which products can be tested?

- 8Factors Affecting the Performance and Accuracy of Tensile Testing Machines

- 9Classification of Tensile Testing Machines

-

-

-

CHINA NBC-1024-2 Tensile Tester 5T$ 6635.00

-

-

-