Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

summary

High-viscosity ultraviolet resin (UV resin) is widely used in optical coatings, electronic device packaging and other fields due to its excellent optical properties and mechanical properties. However, due to its high viscosity characteristics, high requirements are placed on coating equipment and processes. In this study, the feasibility and process optimization method of coating high-viscosity ultraviolet resin on glass substrate were investigated. By adjusting key parameters (coating speed, blade gap, resin pretreatment temperature, etc.), a uniform, high-adhesion coating is achieved. The research results provide a technical reference for the coating of high-viscosity materials.

1. Introduction

Due to their high optical transparency, low shrinkage and excellent mechanical properties, high-viscosity UV resins are often used in precision applications such as display screen protective films and optical lens coatings. However, high-viscosity UV resins have poor fluidity and are prone to problems such as unevenness, blistering, and uncontrollable thickness during the coating process. How to use small coating equipment to achieve uniform coating in a laboratory environment is an important part of material research and application development.

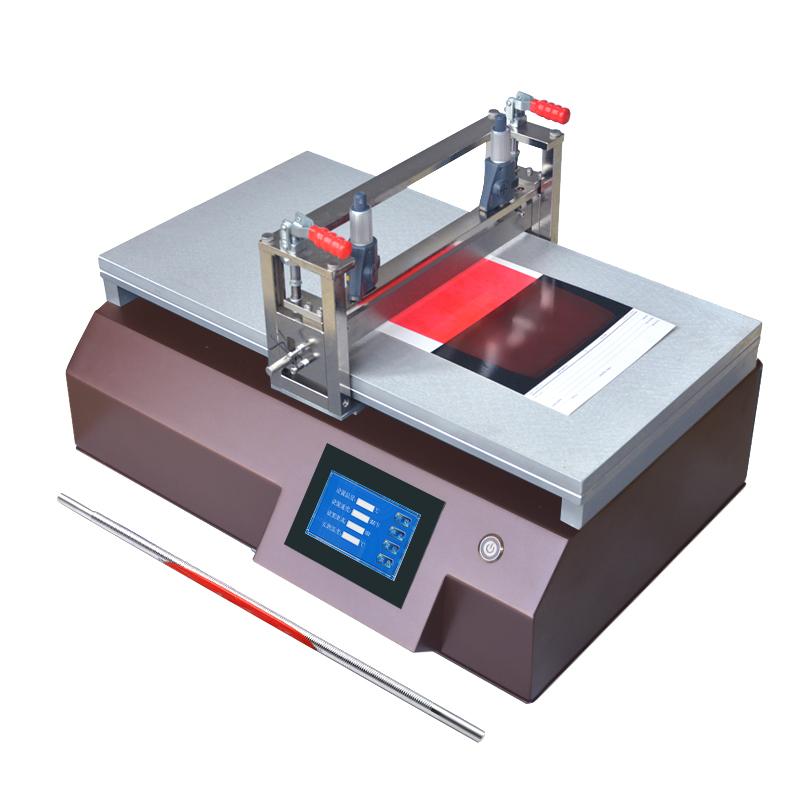

In this study, a laboratory-grade small coating machine was used to explore the optimization of process parameters and technical difficulties in coating high-viscosity UV resin on glass substrates. The experiment focused on the improvement of coating uniformity, thickness controllability and resin adhesion, and the effectiveness of the method was verified by experimental data.

2. Materials and equipment

2.1 Materials

Base material: borosilicate glass sheets (50 mm × 50 mm × 1 mm).

Coated material:High viscosity UV-curable resin (viscosity range: 3000–5000 cps).

Wash the solvent:Absolute ethanol and acetone.

2.2 Equipment

Coating machine:Laboratory small coater with adjustable squeegee blade and vacuum adsorption abutment.

Ultraviolet light source:UV curing lamp with a wavelength of 365 nm and a power of 100 W/cm².

Surface analyzers:Surface roughness Tester and light microscope.

3. Experimental methods

3.1 Substrate pretreatment

The glass substrate needs to be cleaned and activated before coating, and the specific steps are as follows:

Ultrasonicly clean the glass substrate with acetone and absolute ethanol for 10 min each.

The substrate surface is activated using a plasma cleaner for 3 minutes to improve the adhesion of the coating material.

3.2 Coating process

The effect on the coating effect was investigated by changing the following key parameters:

Coating speed: The movement speed of the coater is set at 50–200 mm/s.

Scraper gap:The coating thickness is controlled by the gap between the blade and the substrate and can be set in a range of 10–200 μm.

Resin pretreatment:UV resins are heated to 40°C before coating to reduce their viscosity and improve flowability.

How it works:

1) Fix the glass substrate on the vacuum adsorption abutment table of the coater.

2) Adjust the blade gap and set the coating speed.

3) Evenly add UV resin dropwise to the center of the substrate and complete the uniform coating through the coating machine.

4) The coated sample is cured under a UV light source for 60 seconds.

4. Experimental results and analysis

4.1 Coating uniformity

The surface topography of the coating was observed using an optical microscope, and the results showed that:

When the coating speed is too fast (>150 mm/s), the coating appears to be distinctly streak-like.

When the coating speed is too slow (<50 mm/s), the resin tends to build up, resulting in uneven thickness.

At a speed of 100 mm/s, the coating surface is smooth and homogeneous with no obvious defects.

4.2 Coating thickness control

The blade gap has a significant effect on the coating thickness. Measured by a surface roughness Tester, the coating thickness has a linear relationship with the gap (R² = 0.98). When the gap is set to 50 μm, the coating thickness is about 53 μm and the uniformity is good.

4.3 Adhesion Test

The adhesion of the coating was tested using the 100-grid method and tape peeling, and the results showed:

The substrate without plasma activation has poor adhesion and a peel rate of about 40%.

After plasma activation, the adhesion was significantly improved, and the peeling rate was reduced to less than 5%.

4.4 UV curing effect

After curing, the hardness of the coating reaches more than H level, and there is no adhesion on the surface. The cross-section was observed by scanning electron microscopy, and the cured layer was tightly bonded to the substrate, and there was no obvious interface defect.

5. Discussion

5.1 Technical challenges of high-viscosity resin coating

High-viscosity UV resin coating faces the following challenges:

Poor flowability – the resin is difficult to self-level and is prone to local build-up during the coating process.

Difficulty in thickness control——The high viscosity makes the slight adjustment of the blade gap have a significant impact on the thickness, and it needs to be supported by high-precision equipment.

Bubble problem——The resin is prone to entrainment of air bubbles during the coating process, which affects the quality of the final coating.

In this study, the effects of these problems were successfully reduced by preheating the resin and optimizing the scraper parameters.

5.2 Necessity of Coating Parameter Optimization

The experimental results show that the reasonable matching of coating speed and scraper gap is the key to obtaining high-quality coatings. Under experimental conditions, the combination of a velocity of 100 mm/s and a gap of 50 μm is more appropriate. In addition, plasma-activated treatment of the substrate significantly improves the adhesion of the coating.

6. Conclusion

In this study, the coating process of high-viscosity UV resin on glass substrates was systematically studied based on an experimental small coater. By optimizing the coating speed, blade gap, and resin pretreatment method, a homogeneous, high-adhesion coating preparation was successfully achieved. The main conclusions are as follows:

Reasonable coating speed and scraper clearance can effectively improve the uniformity and thickness controllability of the coating.

Pre-heat treatment of the resin significantly reduces its viscosity and improves coating leveling.

The surface treatment of the substrate has a significant impact on the adhesion of the coating, and plasma activation is a highly efficient method.

This study provides a reference for laboratory coating technology for high-viscosity materials, and future work will focus on the optimization of automated coating processes and their application in actual production.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Experimental application of water-based paints on film laminating paper by laboratory coater

- 3Experimental coater application case video of liquid silica gel on release paper

- 4Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 5Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

- 6Application of small coater in gel coating

- 7Application of small coater in polyimide slurry

- 8Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 9Method and application of experimental coater coating water-based slurry on aluminum foil