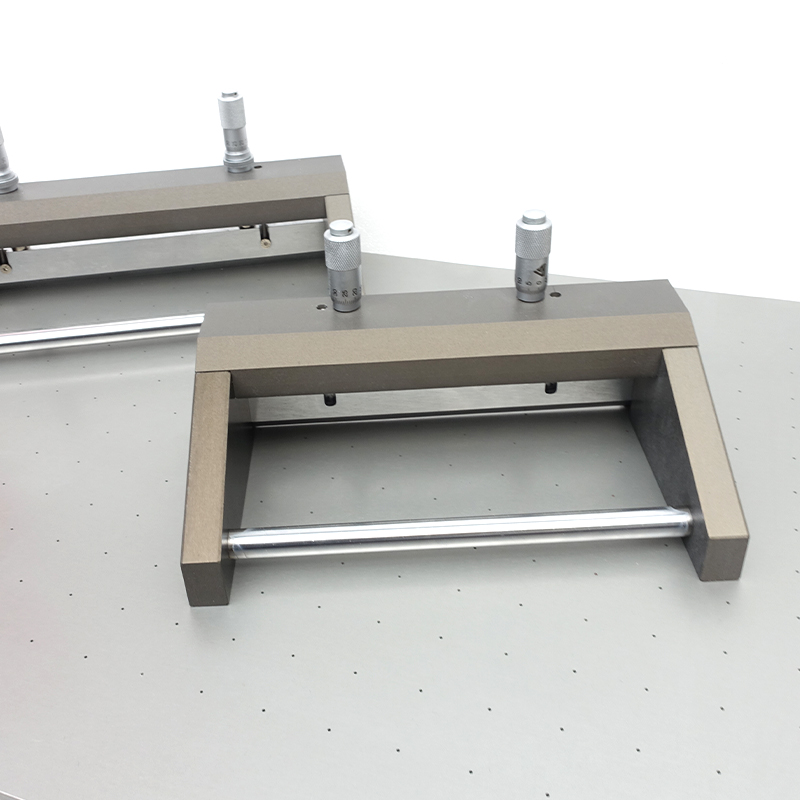

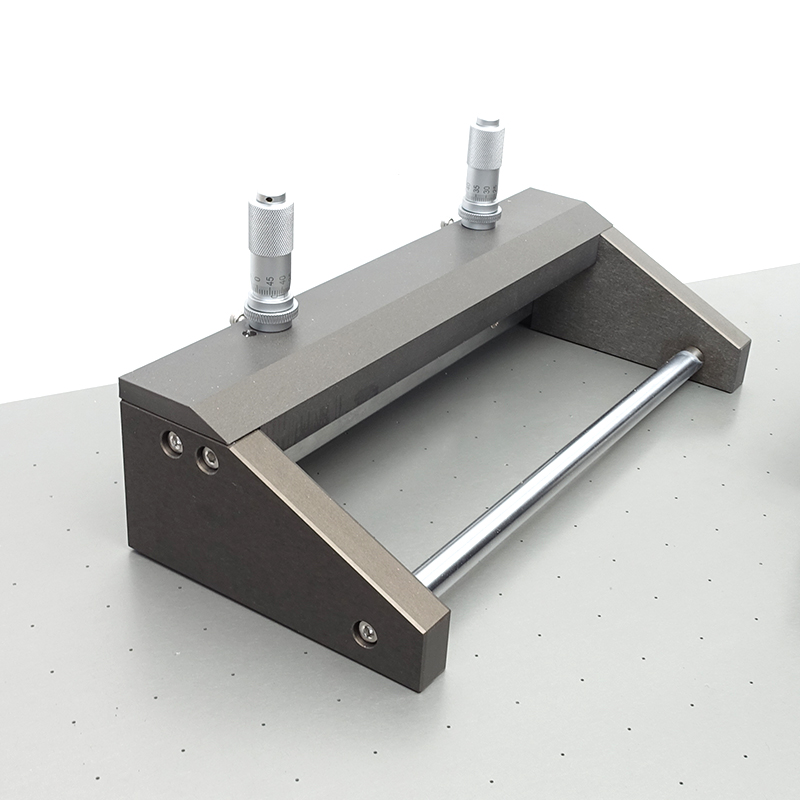

Micrometer Film Applicators

Coating technology is widely used in many industries, including coatings, optical films, electronic components, semiconductors, medicine, and other fields. As a key piece of equipment in this process, the accuracy of the applicator directly determines the quality, uniformity and performance of the final coating. Due to its reliable adjustability and high accuracy, the adjustable Film Applicator (also known as the wet film preparer) has become one of the core tools of the coating process in laboratory and industrial production. This article will introduce in detail the working principle, key technical parameters, application fields and development trends of adjustable Film Applicators.

How it works

The core function of the adjustable Film Applicator is to control the thickness of the coating film by adjusting the gap between the scraper and the substrate. Its working principle is to use the micrometer head to adjust the upper and lower positions of the scraper so that it forms a uniform coating layer on the surface of the substrate. The specific process is as follows:

Adjustable Differentiator – Adjustable Film Applicators are typically equipped with two differentiators that control the position of the squeegee by adjusting the differential head on the differentiator. The microscope head can be adjusted as needed, and the high-precision digital microscope head can be adjusted in units of 1 μm to ensure precise control of the coating film thickness.

Scraper Adjustment – The scraper is a key component of the applicator and is usually made of a material with high wear resistance, such as mold steel. By adjusting the gap between the scraper and the substrate, the thickness of the coating can be directly controlled. The adjustable thickness range of the coater is usually 0~5000μm, which can adapt to different coating needs.

Coating process – When the applicator scrapes on the surface of the substrate, the paint comes into contact with the surface of the substrate through the gap of the scraper and is evenly distributed, forming a uniform wet film layer. This wet film layer is further dried or cured to form the desired thickness of the coating.

Key technical parameters

The performance of an adjustable Film Applicator is determined by a number of key technical parameters, including:

1. Coating film thickness range

The coating thickness of the adjustable Film Applicator is usually between 0~5000μm, and the appropriate thickness range is selected according to different product requirements. For some application scenarios, it can also be customized according to specific requirements.

2. Accuracy and resolution

The accuracy of the coater directly affects the uniformity and quality of the coating layer. There are two common differential heads, the scale differential head usually has an index value of 10 μm, while the digital microscope head provides higher accuracy, and the index value can reach 1 μm. The high-precision digital micrometer head ensures fine adjustment of the coating film thickness and is suitable for the most demanding coating quality control.

3. Coating width

Depending on the application, the coater offers a variety of coating widths, such as 50mm, 100mm, 150mm, 200mm and 250mm. Suitable for different sizes and types of coating needs.

4. Straightness of the scraper

The straightness of the blade is critical to the uniformity of the coating film. The high-precision blade straightness (typically ±2 μm) ensures a flat and smooth coating surface, reducing the risk of uneven coating.

5. Frame and scraper material

The frame material is generally made of aluminum alloy hard oxidation process, which has the characteristics of light weight and high strength, and can effectively withstand the wear and tear caused by long-term use. The scraper is mostly made of mold steel, which has extremely high hardness, wear resistance and corrosion resistance to ensure the stable operation of the Film Applicator in harsh environments.

Fields of application

Adjustable Film Applicators are used in a wide range of industries, especially for high precision and high requirements:

1. Coating industry

In paint production, Film Applicators are used to prepare a uniform wet film to ensure that the thickness and quality of the coating meet the production requirements. Processes such as dispensing, coating and drying rely on adjustable applicators for precise control.

2. Electronics and semiconductor industry

In the manufacturing process of electronic components, thin-film batteries and optoelectronic devices, Film Applicators are used to produce a uniform film layer that meets the stringent requirements for film thickness and uniformity of electronic devices.

3. Optical film manufacturing

Optical films such as reflective, anti-reflective and electromagnetic shielding films require precise coating control. The adjustable Film Applicator provides fine film thickness adjustment to ensure the optical properties of the film.

4. Pharmaceutical and biological fields

In areas such as biofilms, pharmaceutical coatings, and medical device coatings, adjustable Film Applicators provide high-precision coating control to ensure product functionality and safety.

With the continuous development of technology and the diversification of industrial needs, the design and technology of adjustable Film Applicators continue to advance. The future development trend includes intelligence and automation, and the Film Applicator will be more combined with intelligent manufacturing and automatic control technology, and the digital control system will be used to achieve more accurate film thickness adjustment and data traceability; High efficiency, energy saving, environmental protection requirements promote the development of Film Applicators in the direction of more efficient and low energy consumption, reduce energy consumption and improve coating efficiency through optimized design; Multi-functional, future Film Applicators may integrate heating, drying, curing and other functions to meet different industrial needs and improve production efficiency and product quality; The application of high-performance materials and new materials will enhance the stability, durability and corrosion resistance of the Film Applicator, and ensure the stable operation of the equipment in more severe environments.

- 1Preparation of Electrodes with Adjustable Film Coater

朱昱龙 - 《哈尔滨工业大学》

- 2Comparison of different brands of adjustable wet film preparers

- 3I heard you can't find a Film Applicator that can be applied several times?

- 4The principle and structure of adjustable Film Applicator

- 5TQC automatic film machine operation manual

- 6Effect of Carbon Nanotube Spreader on Electrical performance and Optical Properties of Paper

方志强 - 《华南理工大学》

- 7TQC Micrometer Film Applicator Operation Manual

- 8Film prepative method

- 9Pushen KTQ Micrometer Film Applicator