Coating viscosity determination and application of Flow Cup method

In the coatings industry, viscosity is an important indicator to evaluate the fluidity of coatings, and the flow-out cup method is one of the most commonly used measurement methods. With its simple operation, economical and practical characteristics, the outFlow Cup method has become a widely used measurement tool in the coating industry. This article will discuss in detail the principles of outFlow Cups, common types, and related correction methods.

The principle and type of outFlow Cup method

The outFlow Cup method measures the time it takes for a certain amount of paint to flow out of the Viscosity Cup based on the gravitational fluidity of the specimen. Different countries have developed many types of outFlow Cups according to their industrial needs, including the Ford Cup in the United States, the Seepot Viscometer, the DIN Cup in Germany, etc. The standard outFlow Cup adopted in CHINA is Tu-4 cup, while the international standard is ISO outFlow Cup. Parameters such as the pore size, shape and capacity of the outFlow Cup are different, which directly affects the measurement results.

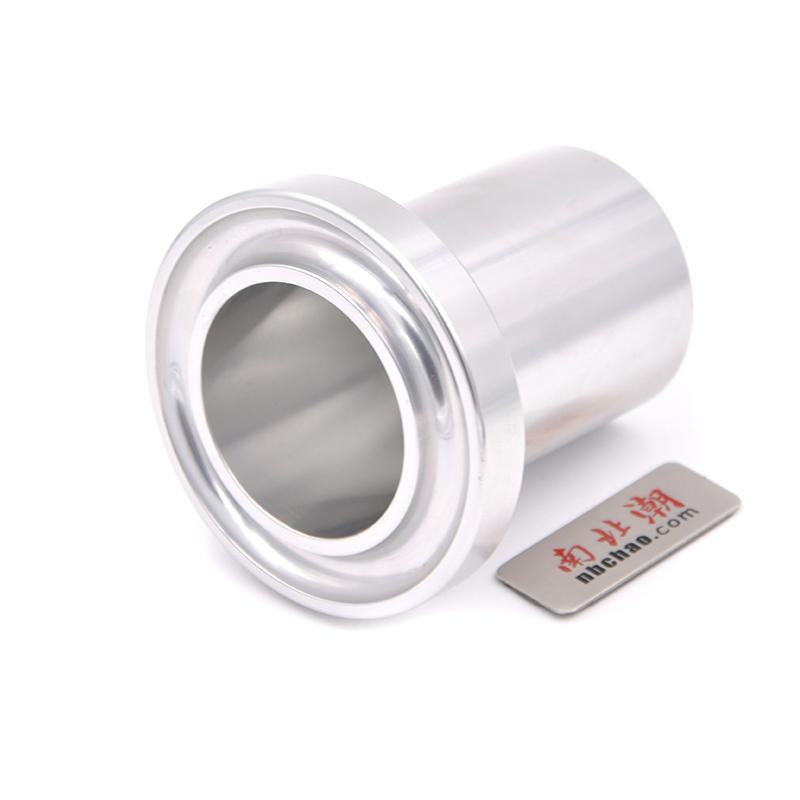

Construction and calibration of Tu-4 viscometer

The Tu-4 viscometer is cylindrical in shape in the upper part and conical in the lower part, with a capacity of 100mL and a standard hole with a diameter of 4mm at the bottom. When using Tu-4 cups, it is important to pay attention to the details of its operation, such as temperature control, liquid type, and uniform handling methods. The Tu-4 cup is mainly used for the measurement of low-viscosity varnishes and basecoats, and the measuring range is suitable for coatings with a kinematic viscosity of 60-360 mm²/s.

The correction methods of Tu-4 cup mainly include kinematic viscosity method and standard viscometer method. The kinematic viscosity method calculates the standard outflow time of -4 cups by means of a characteristic formula based on the kinematic viscosity of the standard oil. The standard viscometer method determines the correction factor of the Tu-4 cup by comparing it with the standard Viscosity Cup. Regular calibration is essential to ensure the accuracy of Tu-4 cup measurements.

Characteristics and development of ISO outFlow Cups

The standardization process of ISO outFlow Cups is relatively complete, and its design takes into account the scope of application of cups with different pore sizes. The ISO outFlow Cup is designed with a design angle of 120°, which is larger than the 81° of the Tu-4 cup, which helps to reduce the turbulent effect when the liquid flows out, thus improving the stability of the measurement. ISO outFlow Cups have a wide range of applications, with a variety of pore sizes (3mm, 4mm, 5mm, 6mm), which are suitable for coatings with different kinematic viscosity ranges.

The correction of the ISO outFlow Cup is more complex, and it is necessary to calculate the corresponding outflow time according to the standard oil with known kinematic viscosity combined with the correction formula. Special attention should be paid to the temperature control during calibration to ensure the accuracy and consistency of the test.

summary

As a simple and practical method for determining the viscosity of coatings, the outFlow Cup method plays an important role in coating production and quality control. With the development of science and technology, the design and correction methods of the outFlow Cup are also constantly improving. In the future, more temperature control devices may be added to the outFlow Cup to improve the accuracy of the test and expand the scope of application, further driving the progress of the coatings industry.