This article takes you into the technical field of immersion coil coater

Immersion coil coater is a kind of equipment used to evenly coat liquid substances on the surface of coil material, which is widely used in coatings, adhesives, films and other industries.

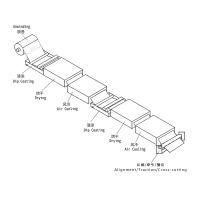

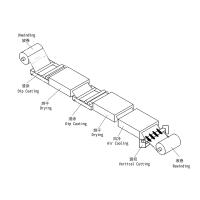

How it works

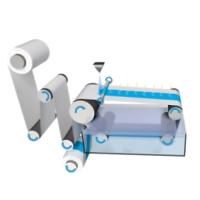

By immersing the coil in the coating tank, the viscosity and surface tension of the liquid in the tank are used to evenly coat the surface of the coil.

Main components

Coating tank – used to store the coating liquid, usually equipped with heating and stirring to maintain the stability of the liquid.

Immersion Roller – Inserts the coil into the coating tank and controls the immersion depth and speed to ensure uniform coating.

Doctor blade system – used to remove excess coating fluid and control coating thickness.

Drying system - the coated coil is dried, often heated by hot air or infrared.

Winding device - rewinds the coated and dried coil into a roll for further processing.

Key technical parameters

Coating speed

Affects production efficiency and coating quality.

Coating thickness

Precise control is required to meet product requirements.

Drying temperature and time

Affects the degree of curing and performance of the coating.

Tension control

Ensure the stability of the coil during the coating and drying process.

Control system

Automatic control - real-time monitoring and adjustment of the coating process through PLC or DCS system.

Sensors - used to monitor parameters such as coating thickness, drying temperature, coil tension, etc.

Safety and environmental protection

Protective measures – e.g. to prevent spilling of coating fluid, overheating of the machine, etc.

Waste gas treatment - the organic waste gas generated in the drying process is treated to meet the requirements of environmental protection.