Coating Thickness Gauge Precautions for use

Coating Thickness Gauge is an instrument used to measure the thickness of coatings (such as paints, plastics, enamels, etc.), which is widely used in machining, chemical industry, automobile manufacturing, aerospace and other fields. Proper use of coating Thickness Gauges is critical to ensuring the accuracy and reliability of measurement results.

Measurement method and principle

Coating Thickness Gauges are mainly based on the principles of magnetic Thickness Gauge, eddy current Thickness Gauge, ultrasonic Thickness Gauge, electrolytic Thickness Gauge and radiometric Thickness Gauge. The magnetic Thickness Gauge method is suitable for measuring the thickness of non-magnetic coatings on magnetically conductive materials (such as steel, iron, etc.); Eddy current thickness measurement is suitable for measuring the thickness of non-conductive coatings; Ultrasonic thickness measurement is suitable for measuring the thickness of multi-layer coatings; Electrolytic and radiometric Thickness Gauges are rarely used due to their complexity or high cost. Different measurement methods are suitable for different materials and application scenarios, and choosing the right measurement method is key to ensuring the accuracy of the measurement results. In practice, magnetic Thickness Gauge and eddy current Thickness Gauge are two of the most commonly used methods, and they are easy to operate and have high measurement accuracy to meet most industrial needs.

Factors influencing the measurement results

A variety of factors can affect the measurement results of a coating Thickness Gauge, including the magnetic and electrical properties of the base metal, the thickness of the base metal, edge effects, curvature, magnetic field interference, surface buildup, probe pressure and orientation, and more. The magnetic and electrical properties of the base metal will affect the accuracy of the measurement results, so the metal magnetism and surface roughness of the standard should be similar to that of the specimen when measuring. The thickness of the base metal also affects the measurement results, and each instrument has a certain maximum critical thickness, beyond which the measurement results are no longer affected by the thickness of the base metal. Edge effects and curvature can affect the reliability of the measurement results, especially in areas close to the edge of the specimen or where the curvature is large, and the measurement data may be unreliable. In addition, the surrounding strong magnetic field, buildup on the surface of the specimen, and the pressure and orientation of the probe can also affect the measurement results. Therefore, it is important to ensure that the surface of the specimen is clean before measuring, to avoid using the instrument in a strong magnetic field environment, and to ensure that the probe is placed smoothly on the specimen and remains vertical. The combined influence of these factors can lead to deviations in the measurement results, so special attention needs to be paid to these details in practice to ensure the accuracy and reliability of the measurement results.

Precautions for use

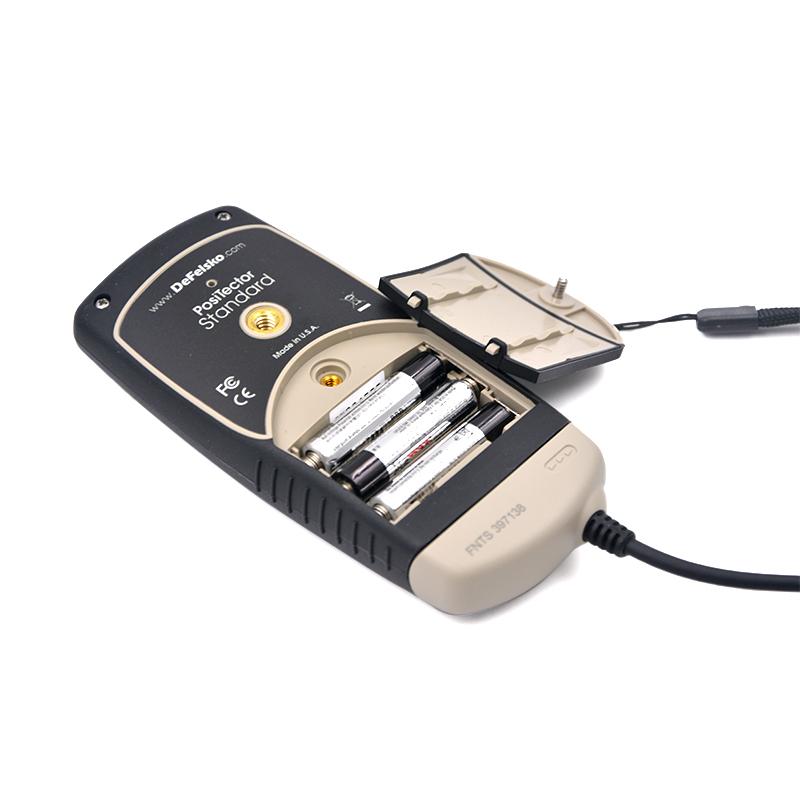

When using a coating Thickness Gauge, you should pay attention to the following: First, make sure that the instrument and probe are clean so that dust and dirt do not affect the measurement results. Secondly, choose the appropriate measurement method and instrument, and choose magnetic thickness measurement method or eddy current thickness measurement method according to the properties of the material to be measured. Before measuring, a zero calibration should be performed on the surface of the uncoated workpiece or on the standard piece to ensure the accuracy of the measurement results. When measuring, the probe should be pressed vertically against the surface of the analyte to keep it stable and avoid dragging the probe. After the measurement is complete, the instrument should be placed back in the protective case to avoid drastic temperature changes. Inspect the probe regularly to clean up any remaining dirt and make sure the probe is clean. When not in use for a long time, the battery should be removed to prevent leakage damage to the instrument. Through these precautions, the measurement accuracy and reliability of the coating Thickness Gauge can be effectively improved, and the coating thickness can be ensured to meet the quality standards. In addition, attention should also be paid to the maintenance and maintenance of the instrument, and the instrument should be calibrated regularly to ensure its long-term stable operation.

Common problems and solutions

When using a coating Thickness Gauge, you may encounter problems such as unstable measurement data and excessive measurement errors. These problems may be caused by the peculiarities of the material structure of the workpiece, excessive surface roughness or excessive surface adhesions. Solutions include selecting a suitable coating Thickness Gauge, grinding the surface of the workpiece, removing buildup, etc. If the measurement error is too large, it may be caused by magnetization of the base metal, too little thickness of the base metal, edge effects, too little curvature of the workpiece, too much surface roughness, magnetic field interference and improper probe placement methods. These interference factors should be troubled and eliminated one by one during the measurement. If the measurement results of the new instrument are not consistent with the original instrument, it may be due to a different calibration base or standard. It is recommended to use the same calibration substrate and standard for calibration. If the instrument still deviates after calibration, it may be due to a discrepancy between the calibration substrate and the DUT material. It is recommended to select a matrix that is consistent with the material of the test piece for calibration. Through these methods, the common problems in the use of coating Thickness Gauges can be effectively solved, and the accuracy and reliability of measurements can be improved. In addition, if the instrument fails, it is recommended to contact professional maintenance personnel for inspection and repair in time to avoid damage to the instrument caused by self-disassembly.

Instrument maintenance and maintenance

The maintenance and care of coating Thickness Gauges is essential to ensure their long-term stable operation. Clean the instrument and probe regularly to avoid the accumulation of dust and dirt. Before use, check the instrument's battery and probe to make sure it is working properly. If the instrument is not used for a long time, the battery should be removed to prevent leakage from damaging the instrument. Calibrate the instrument regularly to ensure the accuracy of its measurements. Avoid using the instrument in environments with high temperatures, high humidity, or strong magnetic fields, which may affect the performance of the instrument. Through regular maintenance and upkeep, the service life of the instrument can be extended, ensuring the accuracy and reliability of its measurement results.

Safety and environmental requirements

When using a coating Thickness Gauge, safety and environmental requirements should also be taken into account. Avoid using the instrument in environments with flammable, explosive, or corrosive gases that may pose a hazard to the instrument and the operator. Appropriate protective equipment, such as gloves and goggles, should be worn during the measurement to protect the safety of the operator. Ensure that the instrument is well grounded during use to avoid measurement errors or damage to the instrument due to static build-up. By complying with these safety and environmental requirements, the safety of the operator and the proper functioning of the instrument can be ensured.

Data logging and analysis

When using a coating Thickness Gauge for measurements, the data of each measurement should be recorded, including the measurement time, measurement location, measurement results, etc. By recording the data, the measurement results can be analyzed to identify potential problems and trends. For example, if the coating thickness in one area is significantly lower than in other areas, it may be necessary to further check the uniformity of the coating. In addition, through data analysis, the coating process can be optimized and product quality can be improved. Regular analysis of measurement data helps to identify and resolve issues in a timely manner to ensure that the coating thickness meets quality standards.

In conclusion, the correct use of coating Thickness Gauges and the above considerations can effectively improve the accuracy and reliability of measurement results, ensure that the coating thickness meets quality standards, and thus play an important role in product inspection. By regularly maintaining and caring for the instrument, complying with safety and environmental requirements, and recording and analyzing measurement data, the effectiveness of the coating Thickness Gauge can be further improved and its service life extended.