Polyurethane-graphene composite prepative film

The coating method is an important technical means widely used in the modification and functionalization of polymer materials. By uniformly dispersing the functional filler in the matrix solution, and then forming a thin film or coating through coating, curing and other processes, the physical and chemical properties of the material can be significantly improved. In recent years, with the deepening of nanomaterial research, graphene has become an important research object in the field of polymer composite materials due to its excellent thermal conductivity, mechanical strength and electrical properties. In this paper, we will discuss the technical application and advantages of coating film method in this field based on the research background of polyurethane-graphene composites.

The basis and process of coating film

1. Basic principles

At the heart of the coating method is the formation of a homogeneous functional coating on or inside the substrate material through a solution dispersion and coating process. The basic steps include:

(1) Solution preparation

Functional fillers (such as graphene) are dispersed in a polymer matrix solution to form a stable suspension or colloid;

(2) Coating

The mixture is evenly coated on the surface of the substrate by scraper, spin coating, spraying and other methods;

(3) Curing and post-processing

The solvent is volatilized by heating, light, etc., to complete the cross-linking and curing of the material, and finally the target composite film is obtained.

2. Process flow

Taking polyurethane-graphene composites as an example, the specific process flow of the coating method is as follows:

Matrix solution preparation——Polyurethane prepolymers are dissolved in an appropriate solvent (e.g., dimethylacetamide or acetone) to prepare a solution of a certain concentration;

Filler dispersion - graphene powder is evenly dispersed in polyurethane solution through ultrasonic treatment to ensure its good dispersion in the matrix;

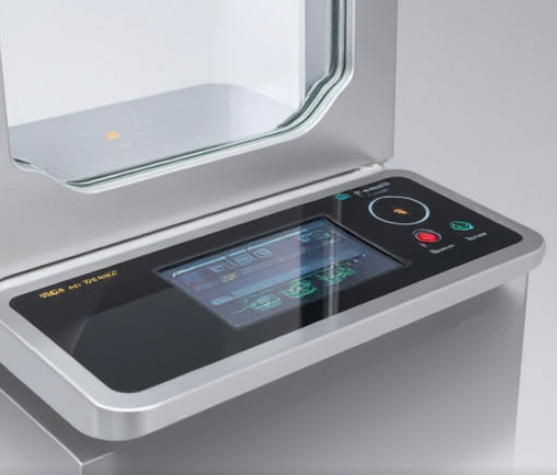

Coating molding - using a scraper or Spin Coater to evenly coat the mixture on the surface of glass, metal foil or other substrates;

Curing and demoulding - the coated sample is heated and cured in an oven, and after the solvent is completely volatilized, the polyurethane-graphene composite film is peeled off.

Advantages of coating film preparation

1. Efficient dispersion and uniformity

The coating method can achieve a uniform distribution of graphene in the polyurethane matrix by means of solution dispersion. Compared with other preparation methods (e.g., melt blending), the coating method avoids the damage to the graphene structure at high temperatures and reduces the possibility of filler agglomeration.

2. Lightweight and high-performance film materials

The composite film prepared by the coating method has excellent mechanical properties and thermal conductivity. Experimental studies show that when the amount of graphene is 1%, the tensile strength of the composite film can be increased by about 30%, and the longitudinal thermal conductivity can be reduced by about 20%, while maintaining good thermal insulation performance.

3. Process flexibility and adjustability

The coating method offers a high degree of process flexibility. By adjusting parameters such as solution concentration, coating speed and curing conditions, it is possible to achieve precise control of the thickness of the composite film (usually between tens of microns and hundreds of microns) to meet the needs of different application scenarios.

Preparation technology by coating method

1. Dispersion and modification of graphene

Graphene is prone to agglomeration in solution due to its high surface activity. To solve this problem, it is usually necessary to modify the surface of graphene (such as the introduction of functional groups such as carboxyl and amino groups) to improve its dispersion and compatibility in polyurethane solutions.

2. Optimization of coating process

Coating speed and tool clearance are key factors affecting film thickness and uniformity. Experiments have shown that an appropriate coating speed (typically 10-50 mm/s) can effectively avoid the formation of bubbles or streak defects, thereby improving the consistency of material properties.

3. Control of curing conditions

Curing temperature and time have an important influence on the crosslinking density and mechanical properties of composite films. Too high a temperature can lead to structural damage to graphene, while too low a temperature can increase the curing time and reduce production efficiency. Typically, the curing temperature can be set to 60-80°C for 12-24 hours.

Polyurethane-graphene composite film has shown broad application prospects in the field of high-performance thermal insulation materials and flexible electronic devices due to its excellent thermal insulation, mechanical properties, good thermal conductivity and flexibility. For example, in the building energy efficiency and aerospace sectors, the material significantly reduces energy consumption and extends service life; In fields such as flexible displays and wearable devices, its thermal management performance has also attracted much attention. However, despite the significant advantages of the coating method in the preparation process, large-scale industrial application still faces challenges, such as the further reduction of graphene production cost and the improvement of coating process efficiency and stability, which will be the focus of future research.

As an efficient and flexible preparation technology for functional materials, the coating method has shown broad application prospects in the research and development of polyurethane-graphene composites. By optimizing the dispersion process, coating parameters and curing conditions, the performance indicators of composite films can be significantly improved to meet the actual needs of different fields. In the future, with the further development of nanomaterial technology and manufacturing process, the coating method will play a more important role in the field of high-performance composite materials.

- 1Thin layer chromatography, TLC method for preparing PLA film

- 2The relationship between film with light, semi-light and no light and actual use

- 3Glossmeter for paints film gloss detection

- 4How to Prepare Graphene Slurry on Aluminum Foil with Film Coater

- 5How can ultra-thin coating film ignore material fineness?

- 64 influencing factors of film precision control

南北潮商城 - 《www.nbchao.com》

- 7Preparation of graphene oxidation films by Mayer Rods

赵玮;荀振亚;张志云 - 《南京信息职业技术学院》

- 8Preparation of silicon oxidation materials by providing hydroxyl groups with methanol

- 9Preparation and testing instrument of water-based acrylic topcoat for steel structure

胡梦 - 《华南理工大学》