Application of Film Applicator in PVDF-HFP Material Research

With the rapid development of new energy technology, solid-state batteries have attracted extensive attention due to their high energy density, high safety and long cycle life. Solid-state electrolyte is one of the core components of solid-state batteries, and its performance directly affects the overall performance of the battery. Polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP), as a typical polymer matrix material, is widely used in the study of solid electrolytes due to its excellent mechanical properties and electrochemical stability.

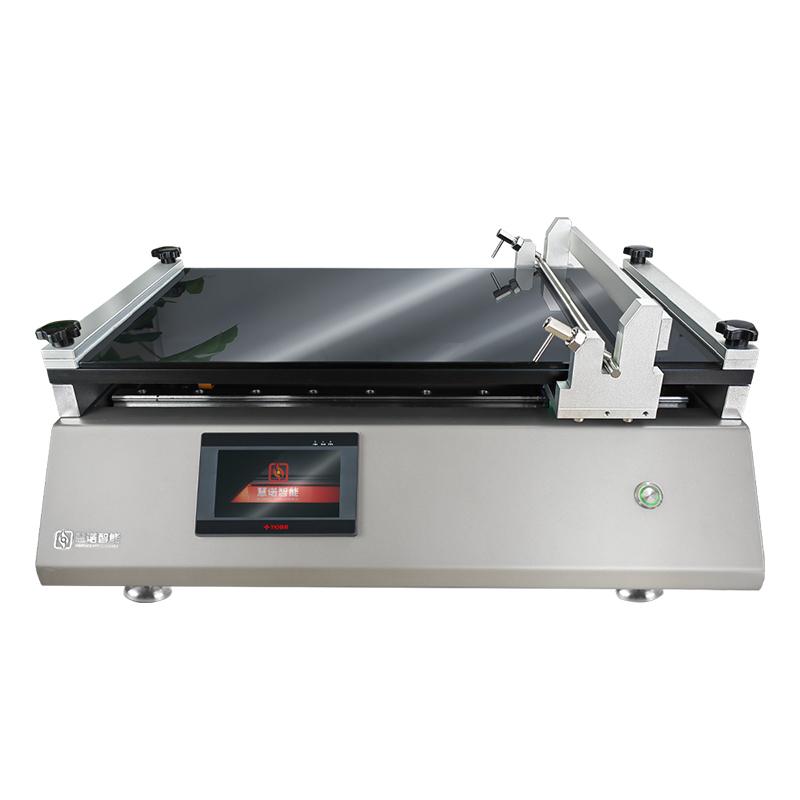

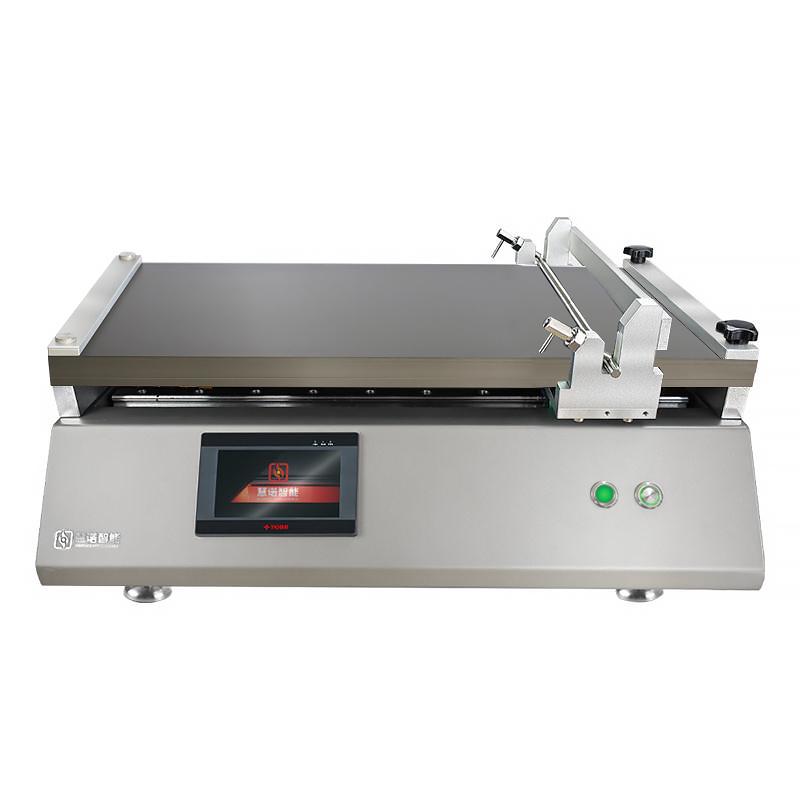

As an important tool for the preparation of thin film materials, the film coater plays a key role in the processing of PVDF-HFP materials. With coating technology, the PVDF-HFP solution can be evenly applied to the substrate to form a dense and stable film. In this paper, we will discuss the application of film coater in PVDF-HFP materials and its impact on the performance of solid-state batteries based on literature research.

Basic properties of PVDF-HFP and its role in solid-state electrolytes

PVDF-HFP is a copolymer composed of polyvinylidene fluoride (PVDF) and hexafluoropropylene (HFP). The presence of polar groups in its molecular structure, such as C-F and C-O bonds, gives it excellent electrochemical properties, including high ion mobility numbers and good mechanical strength. In addition, PVDF-HFP materials have a low crystallinity, which helps to improve their solubility of lithium salts.

In solid electrolytes, PVDF-HFP is usually used as a matrix material and is compounded with lithium salts (such as LiPF6, LiTFSI, etc.) to form a polymer electrolyte film. Not only is this film capable of transporting lithium ions, but it is also chemically and thermally stable and able to operate over a wide range of temperatures.

Application of film coater in PVDF-HFP material

Coating technology is one of the key processes for the preparation of PVDF-HFP-based solid electrolyte films. With a Film Applicator, the PVDF-HFP solution can be evenly applied to a substrate (such as polyester film or aluminum foil) and undergo a drying and curing process to form a dense film.

1. The basic process of the coating process

The basic process of the coating process consists of three main steps: solution preparation, coating and drying and curing:

First, in the solution preparation stage, PVDF-HFP powder is mixed and stirred with lithium salts (such as LiPF6 or LiTFSI) and appropriate solvents (such as DMF or THF) until homogeneous;

Subsequently, the prepared solution is evenly coated on the substrate material by using a film coater, and the coating speed and film thickness can be controlled by adjusting the parameters of the film coater.

Finally, during the drying and curing stage, the coated substrate is heated in an oven to allow the solvent to evaporate and form a dense PVDF-HFP film.

2. The influence of the coating process on the performance of the film

Thickness uniformity is one of the key indicators of coating film quality, and effective control of film thickness can be achieved by adjusting the coating speed and substrate movement speed of the coating machine. In addition, the porosity of PVDF-HFP film directly affects its ionic conductivity, and appropriate drying process can reduce the porosity, thereby improving the compactness, mechanical strength and lithium ion transmission efficiency of the film. The arrangement of the molecular chains (i.e., crystallinity and orientation) of the PVDF-HFP molecular chains during the coating process will significantly affect the physical and chemical properties of the film, and the arrangement of the molecular chains can be controlled to a certain extent by optimizing the parameters such as coating speed and temperature, so as to further improve the overall performance of the film.

The ionic conductivity and mechanical strength of the prepared PVDF-HFP films can be evaluated by testing the electrochemical properties.The application of PVDF-HFP film as a solid-state electrolyte in lithium metal batteries can significantly improve the safety and cycling stability of the battery.The coater plays a key role in the application of PVDF-HFP materials, and by optimizing the coating process parameters, it is possible to prepare solid electrolyte films with excellent performance. This film not only has good ionic conductivity and mechanical strength, but also significantly improves the overall performance of the battery.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in Cosmetic Base Body

- 9Application of Automatic Film Applicator in preparing fluorescent diaphragm