Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

As an inexpensive, abundant and highly conductive material, copper is widely used in the industrial field. However, traditional copper powders have the difficulty of preparing large-area high-conductivity coatings in the industrial coating process. In recent years, two-dimensional (2D) single-crystal copper nanosheets (Cu NPLs) have become reliable materials for flexible electronic devices due to their special physical and electrical properties. In this paper, we introduce a method for the preparation of large-area 2D copper nanosheet films by wire rod coater (Meyer-Rod), and the application of flexible electrodes for rapid preparation by intense pulsed light (IPL) sintering technology.

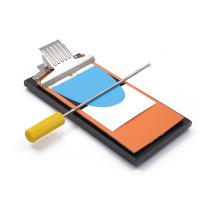

How the wire bar applicator works

The wire rod coater is a tool widely used in the coating industry, especially for the preparation of flexible conductive films. The working principle is to roll the metal rod on the coating solution, so that the coating solution is evenly coated on the substrate through the gap on the metal rod. The rheological behavior and surface tension of the coating solution are the key factors affecting the uniformity of the coating. By adjusting the viscosity of the coating solution, the surface tension, and the coating speed, high-quality film coating can be achieved.

Synthesis and coating of two-dimensional copper nanosheets

In this study, large-size two-dimensional single-crystal copper nanosheets were synthesized by a simple hydrothermal method and applied to the wire rod coating process. The rheological behavior of the coating solution was systematically analyzed by capillary number (Ca) and Reynolds number (Re) to optimize the coating conditions. Experiments show that with the increase of copper nanosheet concentration, the surface tension of the coating solution gradually decreases, and the viscosity increases accordingly. By adjusting the coating speed and the concentration of the coating solution, uniform film coating can be achieved.

Intense pulsed light sintering technology

In order to achieve the sintering of copper thin films in a short time, intense pulsed light (IPL) technology was used in this study. The experimental results show that IPL can complete the sintering of copper films in 1 second, and the resistivity of the films decreases significantly with the increase of energy. When the energy reaches 2.1 J/cm², the resistivity of the film decreases to 1.2 Ω/sq, showing excellent conductivity. In addition, X-ray diffraction (XRD) analysis shows that the oxide layer on the surface of the copper nanosheets is effectively removed during the IPL sintering process, which further improves the conductivity of the film.

Applications of electrochemiluminescent devices

In order to verify the practicability of copper nanosheet films prepared by wire rod coating, they were applied to electrochemiluminescence (ECL) devices. ECL devices have the advantages of simple structure, low driving voltage, low cost, etc., and are not sensitive to the work function of the electrode. The experimental results show that the copper nanosheet film prepared by wire rod coating exhibits excellent conductivity and flexibility in ECL devices, which can meet the performance requirements of the devices.

Large-area two-dimensional single-crystal copper nanosheet films were successfully prepared by wire rod coater, and rapid sintering was achieved by intense pulsed light sintering technology. Through a systematic analysis of the rheological behavior and surface tension of the coating solution, the coating conditions were optimized and a homogeneous film was obtained. In addition, the application of copper nanosheet films in electrochemiluminescent devices demonstrates their great potential in the field of flexible electronics.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in composite coating prepative

- 3Several Common Experimental Spreader Methods and Their Applications

- 4Application of Mayer Rods in Water-based ink Moulding

- 5Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 6The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 7Why Do Film Applicators Need to Change Their Wires Regularly?

- 8Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets

- 9The overlooked role of Mayer Rods in laboratory wet-film preparation