Advantages of drawdown blade method in preparation of perovskite solar cells

In recent years, perovskite solar cells have become a research hotspot in the field of photovoltaics due to their excellent photoelectric properties, low-cost preparation process and adjustable bandgap. However, the traditional spin coating method has problems such as poor uniformity and serious material waste in the preparation of large-area perovskite films, which limits its commercial application. In contrast, as a scalable coating technology, the scraper method has the advantages of simple operation, high material utilization, and suitable for large-area preparation, and has gradually become an important method for the preparation of perovskite films. In this paper, we will focus on the advantages of the scraper method in the preparation of perovskite solar cells, and compare it with the spin coating method.

Comparison of the scraper method and the spin coating method

Film homogeneity and large-area preparation

Spin coating method - by rotating the substrate at high speed, the solution is evenly coated on the substrate by centrifugal force. However, due to the uneven distribution of centrifugal force, the spin coating method is prone to the problem of inconsistent edge and center thickness when preparing large-area films, resulting in poor film uniformity.

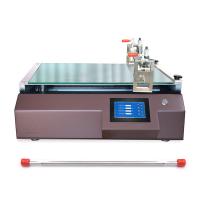

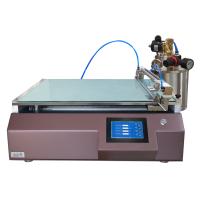

Scraper method - the solution is evenly coated on the substrate through the linear motion of the scraper, which can better control the thickness and uniformity of the film, especially suitable for the preparation of large-area films. The linear coating method of the doctor knife method avoids the difference in film thickness caused by uneven centrifugal force in the spin coating method.

Material utilization

Spin coating method - In the spin coating process, a large amount of solution is thrown out of the substrate due to centrifugal force, and the material utilization rate is low, usually only 10%-20%.

Scraper method – The scraper method can significantly improve the material utilization rate by precisely controlling the coating amount and scraper speed, which can usually reach more than 80%, reducing the preparation cost.

Crystallization control and film quality

Spin coating method - In the process of rapid rotation, the solvent volatilization rate is relatively fast, which can easily lead to uneven perovskite crystallization, pinholes and defects, and affect the quality of the film.

Scraper method – The scraper method can better control the crystallization process of perovskite by adjusting the scraper speed, substrate temperature, and solvent volatilization rate, and obtain a more uniform and dense film. In addition, the scraper method can further optimize the crystallization process and reduce the density of defect states by means of heat- or air-assisted techniques.

Process complexity and equipment costs

Spin coating method - requires high-precision high-speed rotating equipment, and requires high flatness of the substrate, high equipment cost and maintenance cost.

Scraper method - high requirements for the linearity of the scraper, the flatness of the substrate according to the thickness and accuracy of the coating film is different, easy to clean and operate, suitable for laboratory and large-scale industrial production.

The squeegee method can uniformly coat perovskite films on large-area substrates, which is suitable for the large-scale production of perovskite solar cells.The scraper method significantly improves the material utilization rate and reduces the preparation cost of perovskite solar cells by precisely controlling the coating amount. Compared with the spin coating method, the scraper method has obvious advantages in terms of material utilization and cost control.By adjusting the coating parameters (e.g., scraper speed, substrate temperature, etc.), the crystallization process of perovskite can be better controlled and high-quality thin films can be obtained. For example, the perovskite films prepared by the heat-assisted scraper method have higher crystallinity and lower defect density of states, which significantly improves the optoelectronic performance of the battery. In addition to this, alsoIt can be combined with a variety of additive engineering to further optimize the performance of perovskite films. For example, by adding dimethyl sulfoxide (DMSO) or octyl bromide (OABr), the crystallization window of perovskite can be adjusted, the crystallization rate can be delayed, thin film defects can be reduced, and the stability and efficiency of the battery can be improved.

Studies have shown that the perovskite solar cells prepared by the scraper method achieve a PCE of 19.7% in air (humidity > 60%), and the hysteresis ratio is only 3.2%. In addition, the efficiency of the battery prepared by the scraper method can still maintain 92% of the initial value after 500 hours of storage in air, demonstrating its excellent stability.Compared with the spin coating method, the perovskite films prepared by the scraper method have higher uniformity and lower defect density of states, and the open-circuit voltage (Voc) and fill factor (FF) of the cell are significantly improved. For example, a cell Voc prepared by the scraper method reaches 1.12 V, while a cell Voc prepared by the spin coating method is typically below 1.10 V.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2Drawdown blade Film Applicator Coating UV glue on film

- 3Using the drawdown blade Automatic Film Applicator to prepare Resin on Release Paper

- 4Study on Experimental Technique of Scraper Automatic Film Applicator Coating Adhesive on Film

- 5Fuel cell doctor blade Film Applicator: Working Principle and Application

- 6Comparison of advantages and disadvantages of preparing large area perovskite films by doctor blade Spreader method and spin coating method

- 7Perovskite solar cell preparatory method using solvent immersion resistant applicator

- 8Application of Doctor blade Film Applicator in prepative foam coatings

- 9What are the functions of Perovskite Film Applicators?