Determination of coating viscosity Flow Cup

As an important rheological characteristic index of coatings, the viscosity of coatings has a profound impact on the production, construction and final film quality of coatings. Among the many viscosity testing instruments, the outflow viscometer occupies a wide range of applications in the coating industry with its significant advantages of economic and practical operation and convenient operation. The outFlow Cup is a typical representative of this type of viscometer, and its design is born from the capillary viscometer, which has been restructured and amplified to form a variety of models. However, due to the differences in the design standards of outFlow Cups in various countries, the models are complex and there is a lack of unified specifications, which to a certain extent brings challenges to international technical exchanges and cooperation.

Types and Principles

type

Worldwide, there are many different types of outFlow Cups. The United States has Ford Cup (Ford Cup) and Say Bolt viscometers; Germany has DIN cup, Engela (Engler) viscometer; France has Afnor cups, Barbey viscometers; The UK has the BS Cup, the Red-wood viscometer, the Zahn Cup, the Shell Cup and so on. In CHINA, the national standard uses coated - 1 cup and coated - 4 cups, and the International Organization for Standardization recommends ISO outFlow Cups.

principle

The operating principle of the outflow viscometer is based on the gravity of the specimen itself to drive its flow. Specifically, the viscosity of a coating is characterized by measuring the time it takes for a certain amount of sample to flow out of the Viscosity Cup at a specific temperature, in seconds. According to its operating principle, the outflow time (seconds) of the specimen can be converted to a kinematic viscosity value (mm²/s) with the help of characteristic curves. This time-based measure of viscosity provides an intuitive and relatively easy way to determine the viscosity of coatings.

Commonly used outFlow Cups in CHINA

Tu-4 viscometer

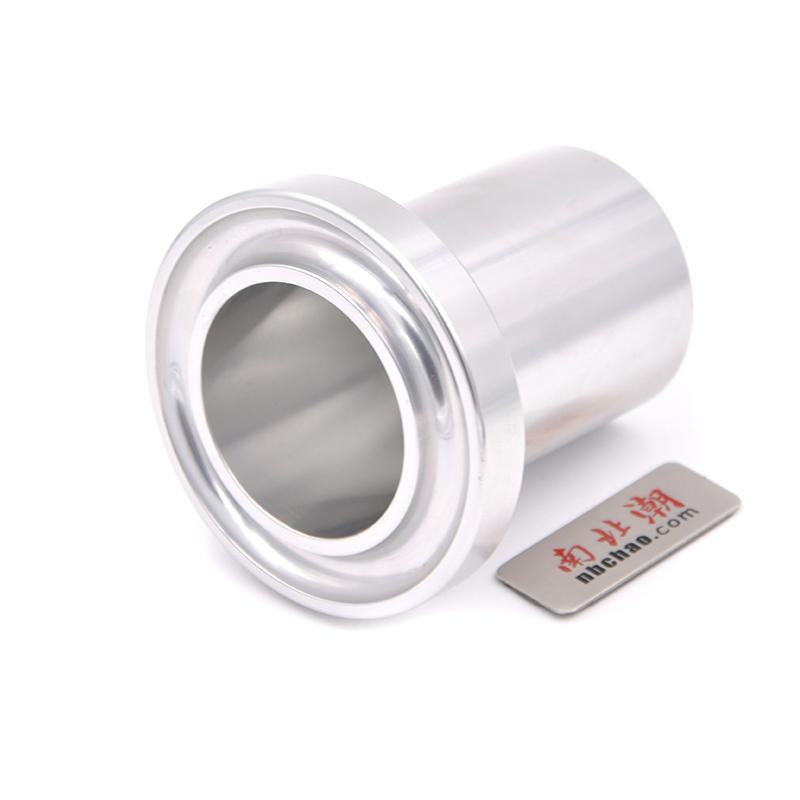

The Tu-4 viscometer has a simple structure, the upper part is cylindrical, the lower part is conical, and the total capacity is 100ml, so it is named because it has a stainless steel leak with a 4mm aperture at the bottom. However, in use, many factors affect the accuracy of the test. The copper cup data on the material is stable, but once the standard hole is improperly installed or damaged during cleaning, changing the volume and hole diameter will interfere with the results. During operation, the temperature has a great influence on the viscosity, so the temperature needs to be constant, and the scraping tool must be unified due to the different surface tension. The viscometer is suitable for Newtonian or near-Newtonian low-viscosity varnishes and basecoats with an optimal determination range of 20 - 100 seconds for outflow times and kinematic viscosity of 60 - 360 mm²/s. The calibration method includes kinematic viscosity method, which uses capillary viscosity to measure the viscosity of standard oil according to the national standard to calculate the standard outflow time; There is also a standard viscometer method, which is suitable for users who do not have accurate temperature control and capillary viscometer, and regularly calibrates with a K-value cup to find the correction coefficient by preparing a mixed oil, while the Engela conditional method is rarely used due to large data deviations.

ISO outFlow Cup

ISO outFlow Cup is developed to unify the standards of outFlow Cups in various countries, from the initial only 1 type of aperture, and gradually form a series of products including 3mm, 4mm, 5mm, 6mm aperture. It is cylindrical in the upper part and conical in the lower part, and is equipped with a protective sleeve. Its cone angle is 120°, which is larger than Tu-4 cups, which can effectively reduce turbulence, the outflow hole length is 20mm, and the L/D is 5, so that the liquid flow is more stable, and the test range is wider, and different pore sizes correspond to different kinematic viscosity ranges. However, it is only suitable for Newtonian or near-Newtonian fluid coatings, and the pore size should be selected before the test to ensure that the outflow time is 30 - 100 seconds. When calibrating, use the known kinematic viscosity standard oil, first draw the viscosity-temperature curve, select the temperature between 20 - 30 °C to measure the outflow time of the standard oil (accurate to 0.2 seconds and within 30 - 100 seconds), and then check the curve to calculate the corresponding outflow time, the difference between the two is not more than 3%, the outFlow Cup is qualified.

Trends

With the continuous progress of science and technology and the increasing requirements of the coating industry for viscosity determination accuracy, the flow-out cup is also continuing to develop and innovate. Internationally, there have been products with temperature control devices added to the outside of the cup, which makes the temperature control during the test more accurate and effectively reduces the impact of temperature fluctuations on the test results. At the same time, in order to meet the needs of convenient use on the construction site, many instrument manufacturers assemble a handle on the outFlow Cup body and build it into a portable Viscosity Cup, which greatly improves the flexibility and convenience of the outFlow Cup in practical applications.

summary

As a cost-effective and widely used tool in the field of viscosity determination of coatings, flow-out cups have played an important role in the development of the coatings industry. Although there is a problem of inconsistent standards in various countries, with the continuous development and improvement of standardized products such as ISO outFlow Cups, as well as the continuous innovation of related technologies, the accuracy, reliability and convenience of outFlow Cups in the determination of paint viscosity will be further improved. In the future, the outFlow Cup is expected to meet the increasingly diverse needs of the coating industry while providing a more solid foundation for international coating technology exchanges and cooperation.