Instructions for use of KS-370 Oscillation Dispersion Testing Machine

1. Overview and safety precautions

Oscillating dispersion testing machine (commonly known as "Blue-devil") is used for rapid and effective vibration dispersion of materials in laboratories such as coatings, dyes, and inks, and can conduct comparative dispersion tests of various materials at the same time.

KS-370 Oscillating Dispersion Testing Machine has two types of column type and floor type, and two configurations of clamping tank configuration and clamping bottle configuration, providing customers with multiple choices. The column type is more convenient to pick and place materials, and the floor type is more stable. The clamping tank configuration can clamp various material tanks prepared by the user (no more than 2.5L on each side, 5L in total on both sides), and the clamping bottle configuration has small glass bottle clamps (4 on each side, a total of eight on both sides) ). Each small glass bottle provided randomly has a volume of about 195mL.

The vibration dispersion testing machine is used in the testing process of chemical products. Users should establish appropriate safety and health protection measures and determine rules and regulations according to relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user and are not within the scope of this manual.

2. Outline drawing

3. Main technical parameters

4. Installation

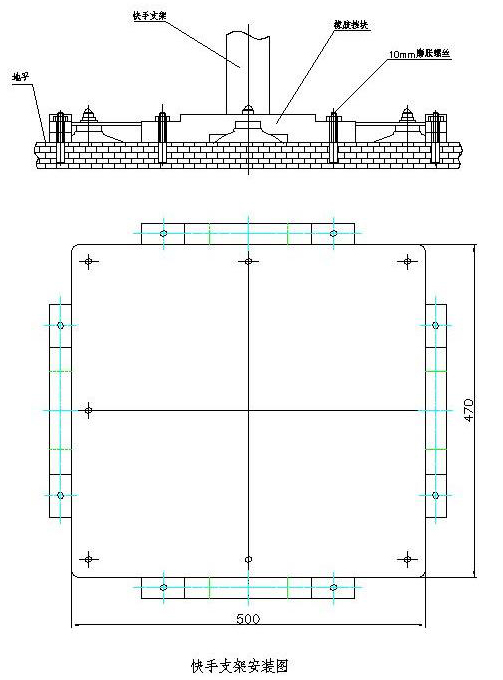

1. Column installation

(1) Install the suction feet on the bottom plate of the column bracket;

(2) After the column is in place, use expansion screws to fix the rubber stopper around the bottom plate of the column (see the figure below);

(3) Install the host on the column bracket.

2. Floor installation

Place the four foot springs in the spring seat holes of the base plate of the main unit to use.

5. Operation overview

1. Put the material to be dispersed and the grinding medium (grinding beads) into the tank (or bottle). Material-bead mass ratio can refer to the table below

Grinding media | glass bead | steel ball |

Material-bead mass ratio | 1:2~3 | 1:3~4 |

2. Put the closed material tank (or bottle) into the clamping device, and turn the handle to clamp it. The clamping force should be appropriate to avoid damage to the can (or bottle) due to excessive force, or cause damage to the clamping device.

3. Try to avoid one-sided canning (or bottle) use. If you do need to use one side, hold a weighted can (or bottle) of water on the other side.

4. If small glass bottles are used in the clamping tank configuration, in order to improve the dispersion efficiency, two small glass bottles can be clamped at a time at a symmetrical position near the outer side of the single-side clamping plate. Also pay attention to the balance on both sides of the holding device.

5. According to the required grinding time, set the timer (randomly equipped, please refer to the timer manual for operation), and start the machine.

6. After the dispersion is completed, please make sure that the machine is completely still before turning the handle to loosen the clamping device and take out the material tank (or bottle).

7. After the work is completed, please disconnect the power supply and do a good job of cleaning and maintenance in time.

8. For the detailed steps and judgment standards of material operation, please refer to the relevant regulations of different products by yourself, which are not within the scope of this manual.

6. How to use the four-hole holder (only available for the clamp bottle configuration)

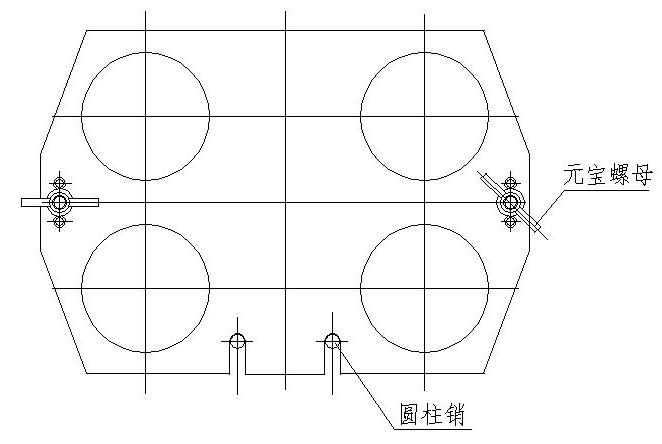

1. Loosen the ingot nuts at both ends, and separate the four-hole holder up and down.

2. Put the small glass bottle into the lower holder (consistent with the specification of the small glass bottle provided at random).

3. Cover the upper holder and tighten the ingot nuts at both ends.

4. Install the entire gripper on the quick gripper.

5. When installing, it should be noted that the two grooves on the four-hole holder need to be aligned with the straight pins on the fast-hand holder; the positioning block on the four-hole holder needs to be above the fast-hand holder.

7. Precautions for use

1. After the new machine has been used for 100 hours, please replace the crankcase lubricating oil. In the future, you only need to check and add it in due course for daily use. Lubricating oil brand: Great Wall brand heat setting machine lubricating oil 4402-1.

2. The total mass of the clamping material tank (or bottle) should not exceed 5 kg, so as not to shorten the service life of the machine.

3. Please do a good job of cleaning and maintenance of the guide rod and screw of the gripper in time to avoid rust or residual foreign matter that makes it difficult to grip forward and backward.

4. In order to prolong the service life of the machine, after working for more than 90 minutes each time, please stop the machine for 10 to 15 minutes to let the machine cool down and then start it.

5. The machine will generate a lot of heat when it is working. Please try to place the machine in a well-ventilated workplace.

6. The company will continuously improve and develop products according to the needs of the market and customers. Subject to change without notice.

- 1A Brief Discussion on the Difference between Disperser and Stirrer

- 2Several Common Coating Dispersers

- 3How to use the Lab Disperser

- 4Inspection Contents of Chemical Plant Disperser

- 5The difference between Disperser ordinary and explosion-proof type

- 6Disperser stirring speed formula

- 7What's wrong with Disperser stirring?

- 8Main Structure of Vacuum Defoaming Disperser

- 9What oil is used in Latex paint Disperser?