Rotational viscometer - principle, classification, application and calibrating

I. Introduction

Viscosity, as the core rheological characteristic parameter of fluids, directly affects the mass transfer, heat transfer and flow behavior in industrial production processes. In the chemical industry, the molecular weight distribution of polymers can be indirectly reflected by viscosity; In the food industry, the taste quality of sauces is directly related to viscosity; The lubricating properties of petroleum products need to be strictly monitored for viscosity indicators. Accurate viscosity measurement is not only the key basis for process control, but also the basis for ensuring product consistency and optimizing equipment operating efficiency.

Due to its wide range and high repeatability, the rotational method has become the mainstream viscosity measurement method in the industry. Compared with the capillary method, which is limited by laminar flow conditions, the Rotational Viscometer can adapt to the measurement needs of low-viscosity solvents (1 mPa·s) to high-viscosity melts (10^6 mPa·s) by adjusting the rotor configuration and rotation speed. Its unique value lies in the fact that it can not only determine the absolute viscosity of Newtonian fluids, but also reveal the thixotropy and shear thinning of non-Newtonian fluids through variable shear rate testing, providing multi-dimensional data support for material research and development.

Second, the working principle

The working principle of a Rotational Viscometer is based on the measurement of the viscous resistance of a fluid to a rotating rotor. When the rotor rotates in the liquid to be measured, the fluid generates shear stresses that hinder rotation, and the viscosity η can be calculated by measuring the torque (M) required to maintain a constant rotational speed, combined with the geometrical parameters of the rotor (radius R1, R2, immersion depth h) and angular velocity (ω). For Newtonian fluids, the viscosity is calculated as:

η=M(R2²-R1²)/(4πhωR1²R2²)

In practical applications, Rotational Viscometers can be divided into two working modes: Searle type (inner cylinder rotation) and Kuette type (outer cylinder rotation). The Searle type has a simple structure but is prone to turbulence, and is suitable for high-viscosity fluids; The Kuette type has a more stable flow field and is suitable for low viscosity measurements. For non-Newtonian fluids, the viscosity varies with the shear rate, which requires correction using a rheological model such as the power-law equation τ=Kγ̇ⁿ.

In order to ensure the accuracy of the measurement, the influence of temperature on viscosity must be considered, and a constant temperature control or temperature compensation algorithm is usually used. Modern Rotational Viscometers also integrate automatic rotor recognition, digital signal processing and other functions, which can achieve accurate measurement from low-viscosity solvents (1 mPa·s) to high-viscosity melts (10⁶mPa·s), which are widely used in chemical, food, petroleum and other industrial fields.

3. Classification and technical characteristics

| Classification by: | type | Technical features: | Typical Applications/Representative Models |

| Classification by structure | Single-cylinder type | - Simple structure and easy installation | Bearingless in-line viscometer |

| - Suitable for continuous in-line measurement | |||

| - Direction of improvement: digital torque sensor, temperature compensation | |||

| Double Cylinder Type (Inner Cylinder Rotation / Searle Principle) | - The outer cylinder is fixed, and the inner cylinder is rotated | Conventional laboratory viscometers | |

| - Turbulence is susceptible and constant temperature control is required | |||

| - Suitable for off-line measurements in the laboratory | |||

| Double-cylindrical type (outer cylinder rotation/Kuette principle) | - The inner cylinder is stationary, and the outer cylinder rotates | High-precision rheometer | |

| - Reduced turbulence for more stable measurements | |||

| - Complex structure and high design accuracy requirements | |||

| Classified by drive mode | Synchronous motor drive | - Conventional drives | Economical viscometer |

| - Stable speed and low cost | |||

| - Suitable for routine industrial measurements | |||

| Servo motor driven | - High control accuracy and fast response | Research-grade rheometer | |

| - Programmable speed regulation to adapt to complex working conditions | |||

| - Suitable for scientific research and high-precision measurements | |||

| Development of new technologies | Modular design | - Automatic rotor recognition | |

| - Smart speed recommendations | |||

| - Quick calibration function | |||

| MCU control and digital display | - Integrated TTS voice broadcasting | Intelligent voice viscometer | |

| - LCD touch screen operation | |||

| - Data storage and export | |||

| Fiber Optic Sensing Technology (FBG) | - Non-contact torque measurement | Rotary FBG viscometer | |

| - Immunity to electromagnetic interference | |||

| - Suitable for extreme environments such as high pressure and high temperature | |||

4. Error analysis and calibration

The measurement error of a Rotational Viscometer is mainly due to temperature variations, non-Newtonian fluid properties, and mechanical factors. Temperature fluctuations can significantly affect the viscosity of fluids, for example, a 0.5°C deviation in temperature may cause some fluids to change viscosity values by more than 5%, so they must be compensated by thermostatic control or by establishing a viscosity temperature curve (e.g., η=9.573T+733). In addition, mechanical factors such as the coaxiality deviation of the rotor and the container and the surface roughness of the rotor can also introduce systematic errors, which need to be eliminated by regular calibration.

For the measurement of non-Newtonian fluids, the traditional viscosity calculation formula can produce significant errors. The viscosity of these fluids varies with the shear rate and needs to be compensated by a modified model (e.g., the power-law equation τ=Kγ̇ⁿ). By iteratively fitting the measured data to the theoretical model, more accurate rheological parameters can be obtained. For example, a yield pseudoplastic fluid needs to be corrected for the measured value by introducing a shear rate correction factor (c=2δ²/[n(δ²+1)]).

Calibration is a key part of ensuring measurement accuracy, including instrument constant calibration and measurement process calibration. The calibration of the instrument needs to be carried out under constant temperature conditions with standard viscosity liquid to establish the torque-viscosity correspondence. The in-line calibration criteria need to be adjusted in real time in combination with process parameters (e.g., melt temperature, pressure). Modern smart viscometers have integrated automatic calibration functions, such as TOV viscometers with temperature/pressure double compensation and gain adjustment, which can control the measurement error in industrial fields to less than 1%.

5. Application and maintenance

Rotational viscometers play a key role in industrial production. In the petroleum industry, it strictly follows the GB/T 10247-2008 standard to test the viscosity of lubricating oil to ensure the lubrication performance of equipment; In the food and chemical industries, online viscometers such as TOV are relied on to monitor the melt characteristics of polymers in real time to ensure product quality. In the field of scientific research, with the help of its accurate measurement capabilities, the rheological behavior of special materials such as lava and glass is studied in depth. In order to obtain accurate data, special attention should be paid to the selection of the rotor according to the viscosity of the sample (to ensure that the torque is in the range of 20%-90%), the temperature is strictly controlled (± 0.5°C fluctuation may bring 5% error), and the inclined immersion method is used to avoid bubble interference. In terms of daily maintenance, it is necessary to clean the rotor surface regularly, carry out periodic verification every six months, and increase the frequency of intermediate self-inspection on important occasions.

At present, Rotational Viscometers still face two major technical bottlenecks: one is the lack of measurement stability under high pressure conditions, and the other is the complexity of non-Newtonian fluid measurement. In response to these problems, the new generation of products is making breakthroughs in three directions: intelligent compensation and automatic rotor recognition through integrated temperature sensors and RFID technology; Development of miniaturized probes using MEMS process to fit into tight spaces; A multi-parameter fusion measurement system was developed to simultaneously acquire viscosity-temperature-shear rate data. In the future, the development trend will be to deeply integrate AI technology, use machine learning algorithms to optimize error correction models, and reduce the manufacturing cost of high-end equipment through modular design, so as to promote the popularization and application of portable high-precision viscometers.

As a central tool for fluid characterization, the Rotational Viscometer continues to revolutionize measurement technology. In practical applications, it is necessary to reasonably select the instrument type according to the characteristics of the measured medium, and strictly implement the standardized operation procedures. In the future, how to improve measurement reliability under extreme working conditions and establish a more complete non-Newtonian fluid characterization system will still be a key technical problem for the industry to overcome.

- 1Application of NDJ-8S digital Rotational Viscometer in viscosity measurement of cosmetic raw materials

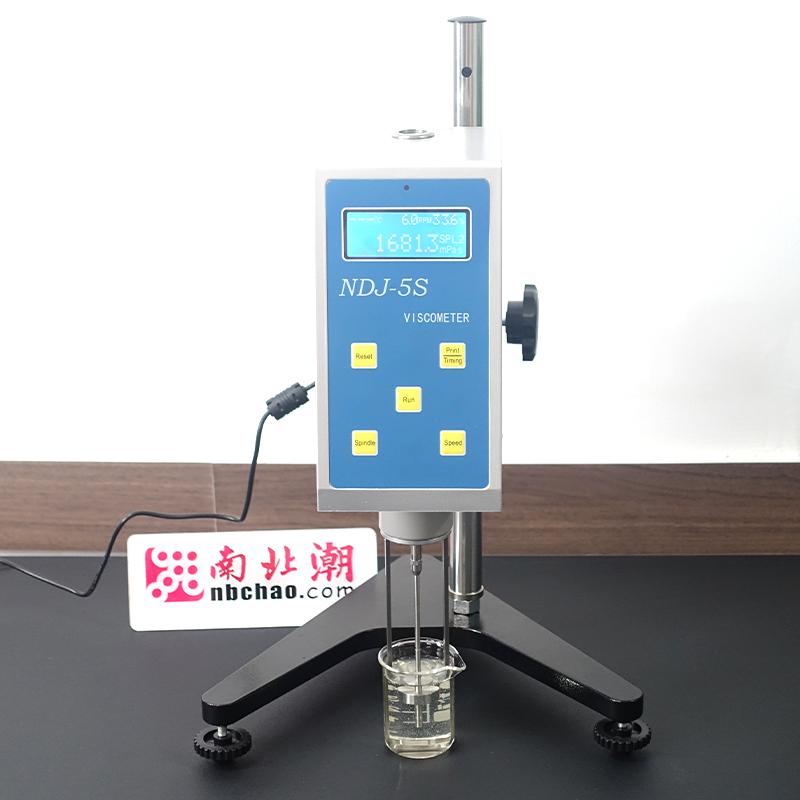

- 2NDJ-5S digital Rotational Viscometer accurate measurement of natural oil viscosity

- 3Application of HBDV-1H swirl/spin High Temperature Viscometer in Viscosity Determination of Plastic Particles

- 4Rotational viscometer selection guide: How to choose the right viscosity equipment for you?

- 5Principle, type and accuracy control of Rotational Viscometer

- 6Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 7Application of Rotational viscometer in Waterborne Polyurethane Adhesive

- 8Application of Rotational Viscometer in cellulose material

- 9Application and selection of digital Rotational Viscometer in polyethylene (PE) wax