Application of Film Applicator in PEM Research and Preparation

Proton Exchange Membrane (PEM) is an ionic conductive polymer film with special functions, which plays a central role in clean energy technologies such as fuel cells and hydrogen production by water electrolysis. Laboratory coaters play an important role in the development and preparation of PEM, allowing the proton exchange membrane material to be uniformly applied to the substrate to form a thin and uniform coating layer through precise control of coating parameters. This article will discuss the application of laboratory film coating machine, key technologies and their specific cases in the field of PEM.

Application scenarios

The coater forms a thin, uniform proton exchange film on a substrate such as carbon paper, PTFE membrane or glass by precisely controlling the coating speed, thickness and drying conditions. The thickness of the film layer is usually 5~50 μm, depending on the needs of the specific application scenario.Film applicators can be used to test the film-forming properties of different formulations, such as Nafion™ mixed with additives, to study properties such as conductivity, mechanical strength, and chemical stability of films. For example, in the development of new composite membranes, the effect of doped silica or graphene on proton conductivity and durability can be verified by coating experiments.Prior to coating, the coater can also be used to surface treat the substrate (e.g. plasma cleaning) to enhance the adhesion of the film to the substrate. This is essential to improve the stability and durability of membrane electrode assemblies (MEAs).

Experimental coating method

Scraper coating

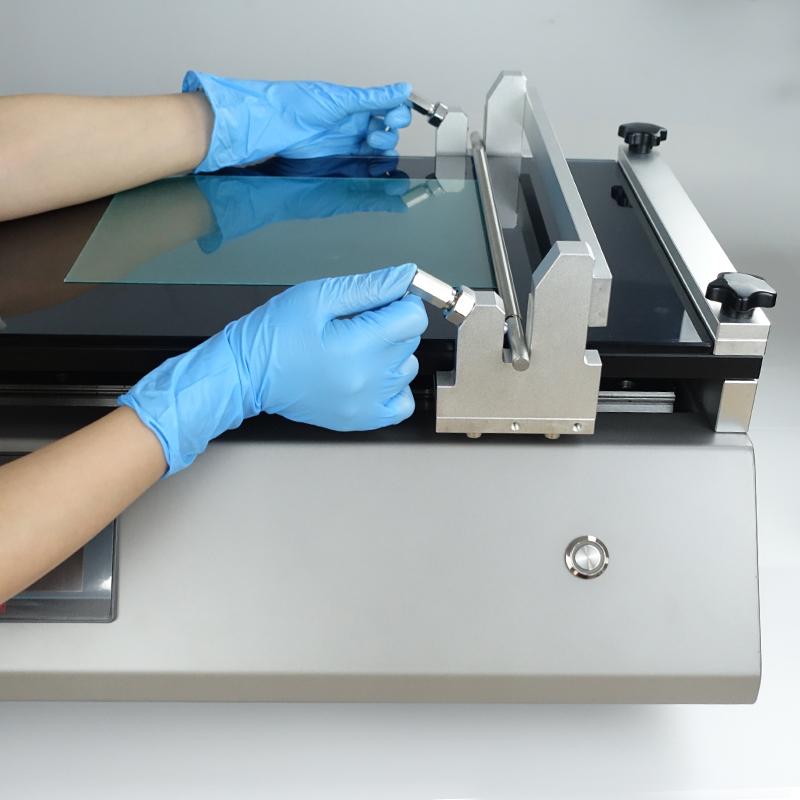

Doctor blade coating is a common laboratory method for the preparation of uniform layers of medium thickness. By adjusting the knife edge height and movement speed, the film thickness can be precisely controlled and cracks or holes can be avoided.

PEM is usually prepared in the form of a resin solution, and a squeegee coater is able to evenly coat a highly viscous resin solution to a substrate material such as PTFE or metal mesh.By adjusting the blade angle, speed and clearance, the thickness of the PEM can be precisely controlled to meet the needs of different application scenarios (e.g., PEM in fuel cells is typically tens of microns thick).Doctor blade coaters are capable of producing films with a flat surface and no defects, helping to improve the electrochemical performance and durability of PEM.

Compared to other coating methods such as spin or roll coating, the squeegee coater is able to handle a wider range of materials, especially highly viscous PEM resin solutions. This technology allows for precise control of film thickness by adjusting the blade angle, speed and clearance, and is suitable for different sizes of substrate materials. In addition, the operation of the squeegee coater is relatively simple, which is suitable for small batch sample preparation or pilot production in the laboratory.Compared to roll-to-roll coating systems, the initial investment is lower and maintenance costs are lower. At the same time, it is able to complete multiple experiments in a short period of time, helping researchers quickly optimize the preparation process parameters of PEM.

Spin coating technology

Spin coating is suitable for the preparation of ultra-thin films (<5 μm), especially when studying the surface topography and interfacial properties of the film. However, this method is usually suitable for small area substrates.

Spraying technology

Spraying technology is particularly suitable for coating complex shapes or large areas of substrates by atomizing the solution and spraying it evenly onto the substrate. Although uniformity control is difficult, membrane performance can be optimized by stacking multiple layers.

Roll-to-roll coating

Roll-to-roll coating is a continuous process that is suitable for industrial production. In the laboratory, this technology is rarely used, but it has important application value in the pilot stage.

Precautions

The coating effect is greatly affected by the viscosity of the solution, the solids content and the type of solvent. For example, Nafion™ solutions typically need to be adjusted to a concentration range of 5~20 wt% to ensure good film-forming properties.In squeegee coating, the height of the knife edge and the speed of movement directly determine the film thickness; In spin coating, the higher the rotational speed, the thinner the film layer. These parameters need to be optimized according to the specific experimental needs.After coating, it needs to be dried slowly (such as 60~80°C) to avoid the formation of cracks or holes. High-temperature sintering (e.g. 120°C) further enhances the compactness and mechanical strength of the membrane.During the experiment, the humidity should be kept stable (e.g., 40~60% RH) to prevent the film from drying too quickly and causing defects.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PVDF-HFP Material Research

- 8Application of Film Applicator in Cosmetic Base Body

- 9Application of Automatic Film Applicator in preparing fluorescent diaphragm