Using the drawdown blade Automatic Film Applicator to prepare Resin on Release Paper

In modern materials science, resin coating technology is widely used in packaging, electronics, optics and other fields. As an important substrate, release paper is often used to coat resin coatings to prepare protective films or composite materials due to its excellent high temperature resistance and low surface energy characteristics. The squeegee coater is a high-precision coating machine that enables uniform thickness control in experimental tests and continuous production. However, due to the high viscosity properties of the resin material and the physical properties of the release liner substrate, how to stably prepare a high-quality resin coating on the release liner?

Materials & Equipment

Substrate: Polypropylene release liner (thickness 50 μm, surface energy ≤ 38 mN/m).

Resin material: epoxy resin (EPON 862), formulated as an aqueous emulsion with a solid content of 40%.

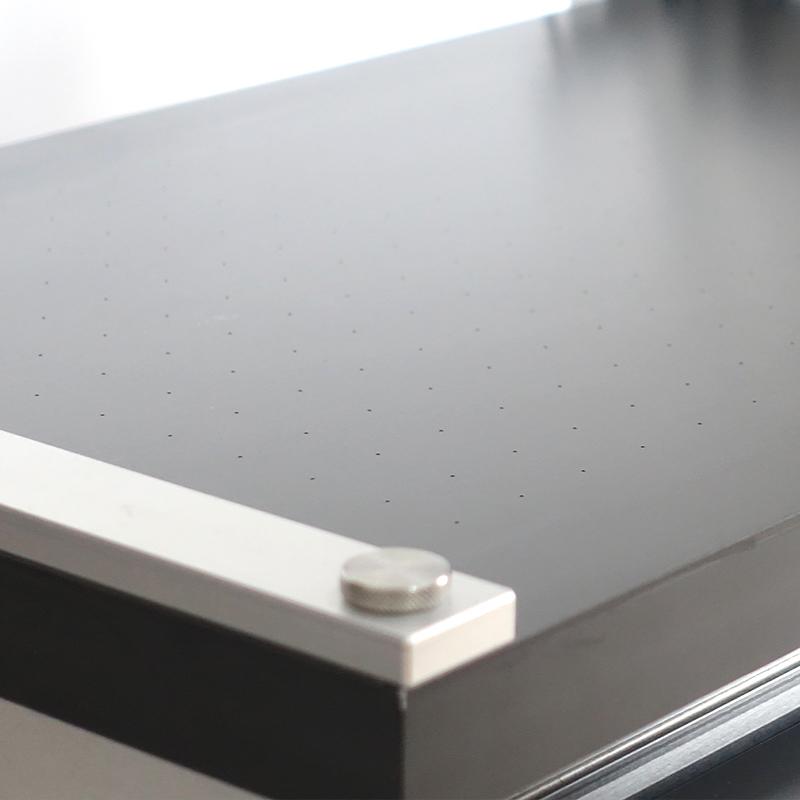

Coating equipment: Huinuo TM3300 precision doctor blade Film Applicator (equipped with adjustable gap tool, vacuum adsorption platform and heating module).

Process

The release liner substrate needs to be cleaned to remove surface impurities. combineThe substrate is fixed with the TM3300 Vacuum Adsorption System for Film Applicator to ensure flatness.The resin emulsion is conveyed to the coating head via a metering pump or manually.The squeegee gap (i.e., the thickness of the coating film) is fine-tuned by adjusting the screw, and the range is 100~300μm.The coating speed control is adjusted according to the rheological properties of the resin.After coating, the wet film enters the heating module (temperature range: room temperature to 300°C) to achieve resin curing and foaming.

Precautions

The tool clearance directly determines the thickness of the resin coating.substrateFlatness also affects coating flatness. However, how to ensure the accuracy of the scraper gap, that is, the accuracy of the wet film thickness of the controlled quantity, the following conditions need to be met:

(1) The coating table is flat enough

(2) The straightness of the scraper is high enough

(3) The differential that adjusts the scraper gap is precise

(4) The substrate release paper is smoothed by vacuum adsorption

How to choose a doctor blade coater?

When selecting a doctor blade coater, the first step is to identify the process requirements, including capacity requirements, coating thickness accuracy, and the type of substrate (film, paper, foil, etc.). The type of machine that is suitable for these needs is selected, and the technical parameters of the machine are also taken into account, such as the maximum coating speed, the minimum tool clearance, the level of the heating temperature, and the uniformity.

The configuration flexibility of the device is also evaluated. For example, whether multiple tool types (e.g. flat, round, or angled) are supported to accommodate different coating thicknesses, whether there is precise speed adjustment to avoid uneven coating due to too fast or too slow flow rates, and whether the blades are easy to clean. In addition, the power of the heating system and the accuracy of the temperature control are also key factors, especially for processes that require high-temperature curing.

Huinuo film coating machine adopts clamshell design, which is easy to scrape and clean. The high-straightness scraper with the green micrometer head can ensure the accurate adjustment of the gap height, and with the module driven by the servo motor and the high-flatness coating table with hard anodic oxidation, the 0.8mm vacuum adsorption aperture is not afraid of thinner films, and the equipment is equipped with an external Vacuum Pump that can work for a long time, making the experiment more convenient!

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2Drawdown blade Film Applicator Coating UV glue on film

- 3Advantages of drawdown blade method in preparation of perovskite solar cells

- 4Study on Experimental Technique of Scraper Automatic Film Applicator Coating Adhesive on Film

- 5Fuel cell doctor blade Film Applicator: Working Principle and Application

- 6Application of Doctor blade Film Applicator in prepative foam coatings

- 7Laboratory Coating Machine Case | Sewage Treatment Flat Membrane/Vinylidene Fluoride PVDF Preparation

- 8Scraper film coater can be used to prepare modified polyolefinic diaphragm on PP film

- 9Scraper Coater Application: Preparation of Foam Coating on Fabrics

张月 - 《东华大学》