Weifu Coating Thickness Gauge instruction manual

1 Overview

This instrument is a portable measuring instrument, which can measure the thickness of coating and plating quickly, without damage, and accurately. It can be used both in the laboratory and in the engineering field. By using different measuring heads, a wide range of measurement needs can also be met. This instrument can be widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and other testing fields. It is an instrument required for the material protection profession.

This instrument complies with the following standards:

GB/T 4956─1985 Measurement of thickness of non-magnetic overlay on magnetic metal substrate -- Magnetic method

GB/T 4957─1985 Measurement of thickness of non-conductive overlay on non-magnetic metal substrate -- Eddy current method

JB/T 8393─1996 Magnetic and eddy current cladding thickness measuring instrument

JJG 889─95 Magnetoresistive Thickness Gauge

JJG 818─93

Peculiarity:

*Two thickness measurement methods, magnetic and eddy current, can measure the thickness of the non-magnetic covering layer on the magnetic metal matrix and the thickness of the non-conductive covering layer on the non-magnetic metal matrix;

*The instrument can be calibrated by using two methods: single-point calibration and two-point calibration, and the systematic error of the measuring head can be corrected by the basic calibration method to ensure the accuracy of the instrument in the measurement process;

*It can quickly and automatically identify ferrous and non-ferrous substrates

*It has the function of power supply undervoltage indication

* There is a beep prompt during the operation;

*There are two shutdown modes: manual shutdown mode and automatic shutdown mode;

*There is a negative number display function to ensure the calibration accuracy of the instrument at the zero point;

*There is a function to display the average, maximum and minimum values[*];

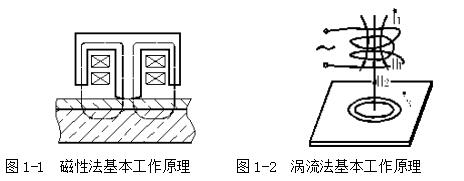

1.1 Measuring principle

This instrument adopts two methods of magnetic and eddy current thickness measurement, which can non-destructively measure the thickness of the non-magnetic covering layer (such as aluminum, chromium, copper, enamel, rubber, paint, etc.) on the magnetic metal matrix (such as steel, iron, alloy and hard magnetic steel, etc.) and the thickness of the non-conductive covering layer (such as enamel, rubber, paint, plastic, etc.) on the non-magnetic metal matrix (such as copper, aluminum, zinc, tin, etc.).

a) Magnetic method (F-type measuring head)

When the measuring head is in contact with the overlay, the measuring head and the magnetic metal substrate form a closed magnetic circuit, and the magnetic circuit reluctance changes due to the presence of the non-magnetic overlay, and the thickness of the overlay can be derived by measuring its change.

b) Eddy current method (N-type measuring head)

A high-frequency alternating current is used to generate an electromagnetic field in the coil, and when the measuring head is in contact with the overlay, eddy currents are generated on the metal substrate and a feedback effect is generated on the coil in the measuring head, and the thickness of the overlay can be derived by measuring the magnitude of the feedback action.

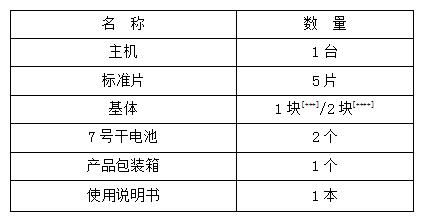

1.2 Configuration Checklist

1.3 Technical Parameters

●Measuring range: 0-1250um[+] 0-1500um[++]

● Working power supply: Two No. 5 batteries

●Measurement accuracy error: zero calibration ± (1+3%H); Two-point calibration ± [(1%~3%H)] H+1.5

● Ambient temperature 0-40°C

●Relative humidity≤85%

●The minimum substrate is 10*10mm, the overall area is greater than or equal to 2cm, and the diameter of the garden is not less than 2MM.

●The minimum curvature is convex 5mm; Concave 5mm

●The thinnest substrate: 0.4mm

●Weight: 99g (including battery)

●Size: 102mm *66mm *24mm

[* ] Single-base, double-base basic version [**] Double-base enhanced version [*** ] Single-base [****] Double-base

1.3.1 Power supply

2×1.5V AA (No. 5)

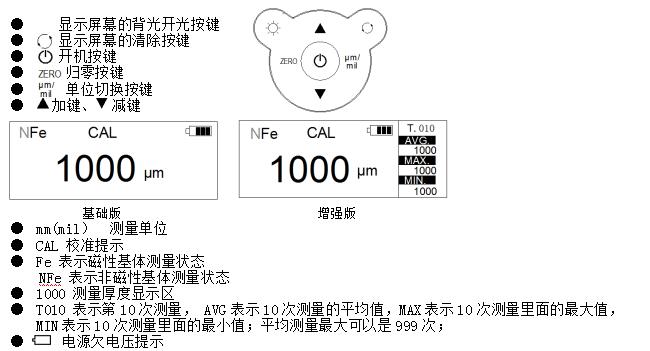

2. Button and display instructions

3 Instructions for use

1) Power on

After pressing the ON button, the instrument hears a beep, and automatically restores the parameter settings before the last shutdown, 0.0μm will be displayed, and the instrument will enter the state to be measured. The workpiece can now be measured. After a period of non-use, the instrument will automatically shut down.

2) Shut down

In the absence of any operation, the instrument automatically shuts down after approximately 3 minutes. Press the "ON" button once to power off immediately.

3) Unit Conversion (Metric to Imperial Conversion)

In the state to be measured, the unit of measurement can be converted by μm/mil.

4) Measurement

a) Prepare the test piece

b) Whether the instrument needs to be calibrated and, if so, the appropriate calibration method is selected (refer to 4 instrument calibration)

c) Quickly contact the measuring head perpendicular to the test surface and gently press the measuring head positioning sleeve, with a beep, the screen displays the measured value, and the instrument will automatically sense the tested substrate: when it senses that it is a magnetic substrate, the instrument displays Fe; When a non-magnetic metal is sensed, the instrument displays NFe. Always keep the instrument vertical when measuring! Lift the measuring head to make the next measurement;

4 Calibration of the instrument

In order for the measurement to be accurate, the instrument should be calibrated at the measuring site.

4.1 Calibration Standards (including foil and substrate)

A foil of a known thickness or a specimen of a known overlay thickness can be used as calibration standards. Abbreviated as standard film.

a) Calibration foil

For magnetic methods, "foil" refers to a foil or gasket that is non-magnetic metal or non-metal. For the eddy current method, plastic foil is usually employed. "Foil" facilitates calibration on curved surfaces and is more suitable than using a standard sheet with an overlay.

b) Standard sheets with overlay

A covering layer of known thickness, homogeneous, and firmly bonded to the substrate is used as the standard sheet. For the magnetic method, the overlay is non-magnetic. For the eddy current method, the overlay is non-conductive.

4.2 Substrates

a) For the magnetic method, the magnetic and surface roughness of the base metal of the standard sheet should be similar to that of the base metal of the test piece. For the eddy current method, the electrical properties of the base metal of the standard sheet should be similar to that of the base metal of the test piece. To confirm the suitability of the standard, the base metal of the standard can be compared with the readings measured on the base metal of the test piece.

b) If the thickness of the metal substrate of the test piece does not exceed the critical thickness specified in Table 1, the following two methods can be used for calibration:

1) Calibrate on a metal standard with the same thickness as the metal substrate of the test piece;

2) Use a metal liner metal standard piece or specimen of sufficient thickness and similar electrical properties, but there is no gap between the base metal and the gasket metal. For specimens with covering layers on both sides, the liner method cannot be used.

c) If the curvature of the overlay to be measured has reached a point where it cannot be calibrated on a flat surface, the curvature of the standard sheet with the overlay or the curvature of the base metal placed under the calibration foil should be the same as that of the specimen.

4.3 Calibration Methods

There are three calibration methods used in this instrument: zero point calibration, two-point calibration, and a six-point correction calibration for the measuring head. The calibration method of this instrument is very simple.

4.3.1 Zero point calibration

a) Take a measurement on the substrate and the screen shows <×.×m >.

b) Press the ZERO button, and the screen display <0.0>. The calibration is complete and the measurement can begin.

c) Repeat the above steps A and B to obtain a more accurate zero point and high measurement accuracy. Once the zero calibration is complete, the measurement can be taken. Note: This instrument provides a negative number display, which is more convenient for users to select the zero point.

4.3.2 Two-point calibration

This calibration method is suitable for high-precision measurements and small workpieces, hardened steels, and alloy steels.

a) Proofread Zero (as above).

b) A measurement is taken on a standard sheet with a thickness approximately equal to the estimated thickness of the covering layer to be measured, with the screen showing <××× m>.

c) Use the ↑↓ key to correct the reading so that it reaches the standard value. The calibration is complete and the measurement can begin.

Note: When the instrument is calibrated, a single press will jump a number, and a long press will not be released, and the value to be corrected will be continuously beaten.

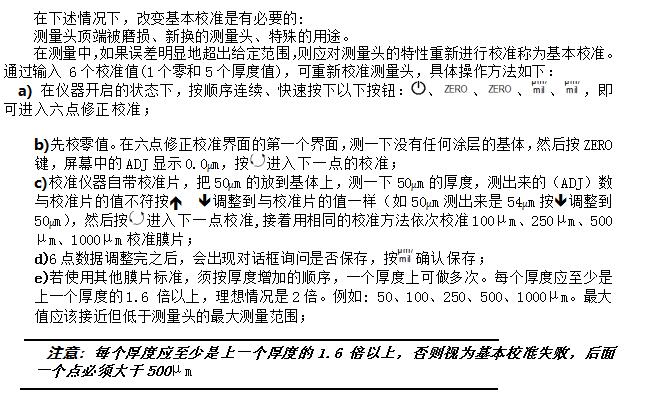

4.4 Six-point correction calibration

5. Factors that affect the accuracy of measurement

5.1 Influencing factors related table

5.2 Explanation of influencing factors

a) Magnetic properties of the base metal

In order to avoid the influence of heat treatment and cold working factors, the instrument should be calibrated with a standard piece with the same properties as the base metal of the specimen. It can also be calibrated with the specimen to be coated.

b) Electrical properties of the base metal

The conductivity of the base metal has an impact on the measurement, and the conductivity of the base metal is related to its material composition and heat treatment method. The instrument is calibrated using a standard piece with the same properties as the base metal of the specimen.

c) Thickness of the base metal

Each instrument has a critical thickness of the base metal. Above this thickness, the measurement is not affected by the thickness of the base metal. The critical thickness values of this instrument are shown in Table 1.

d) Edge effects

This instrument is sensitive to steep changes in the surface shape of the specimen. Therefore, it is unreliable to take measurements close to the edge of the specimen or at the inner corner.

e) Curvature

The curvature of the specimen has an effect on the measurement. This effect always increases significantly with the decrease in the radius of curvature. Therefore, measurements on the surface of curved specimens are unreliable.

f) Deformation of the specimen

The measuring head deforms the soft-covered specimens, so reliable data is measured on these specimens.

g) Surface roughness

The surface roughness of the base metal and overlay has an impact on the measurement. As the roughness increases, the impact increases. Rough surfaces can cause systematic and accidental errors, and each time you take a measurement, you should increase the number of measurements at different positions to overcome this accidental error. If the base metal is rough, it is also necessary to take several positions on the uncoated base metal specimen with similar roughness to calibrate the zero point of the instrument; Or dissolve and remove the covering layer with a solution that does not corrode the base metal, and then calibrate the zero point of the instrument.

h) Magnetic field

The strong magnetic field generated by various electrical equipment around will seriously interfere with the magnetic thickness measurement work.

i) Adhesion substances

The instrument is sensitive to adherent substances that prevent the sensor from coming into close contact with the surface of the overlay, so it is necessary to remove the attached material to ensure direct contact between the instrument head and the surface of the test piece.

j) Measure head pressure

The amount of pressure exerted by the measuring head on the specimen affects the measured reading, so it is important to keep the pressure constant.

k) Orientation of the measuring head

The way the measuring head is placed has an impact on the measurement. During the measurement, the measuring head should be kept perpendicular to the surface of the specimen.

5.3 The regulations that should be observed when using the instrument

a) N matrix metal properties

For the magnetic method, the magnetic and surface roughness of the base metal of the standard should be similar to that of the base metal of the specimen.

For the eddy current method, the electrical properties of the standard sheet matrix metal should be similar to those of the specimen matrix metal.

b) Thickness of the base metal

Check that the base metal thickness does not exceed the critical thickness, and if not, it can be calibrated using one of the methods in 3.3).

c) Edge effects

Measurements should not be made at abrupt changes in close proximity to the specimen, such as edges, holes, and inner corners.

d) Curvature

It should not be measured on the curved surface of the specimen.

e) Number of readings

Often, since each reading of the instrument is not exactly the same, several readings need to be taken within each measurement area. Local differences in the thickness of the overburden also require multiple measurements in any given area, especially when the surface is rough.

f) Surface cleanliness

Before measuring, remove any adherent materials such as dust, grease and corrosion products from the surface, but do not remove any covering substances.

6. Maintenance and repair

6.1 Environmental requirements

Collision, heavy dust, moisture, strong magnetic field, oil pollution, etc. are strictly avoided.

6.2 Replace the battery

When the battery voltage is too low, that is, the battery logo on the screen is empty, and the battery should be replaced as soon as possible. When replacing the battery, special attention should be paid to the direction of the positive and negative polarity of the battery installation.

6.3 Troubleshooting

- 1What is the significance of coating Thickness Gauge calibration? How to calibrate? When to calibrate?

- 2Video takes you to experience PosiTector 6000 series advanced Coating Thickness Gauge

- 3Ultrasonic Thickness Gauge TT100/TT100A Operating Application Instructions

- 4TT120 Ultrasonic Thickness Gauge Operation Application Instructions

- 5Deguang DC-2000B Intelligent Ultrasonic Thickness Gauge User Manual

- 6Introduction of calibrating method of metal coating Thickness Gauge

- 7Defelsko Positector 6000 Advanced Coating Thickness Gauge Instructions for use

- 8Positector6000 Standard Coating Thickness Gauge Detailed instructions for use

- 9Coating Thickness Gauge usage and operation steps