Drawdown blade Film Applicator Coating UV glue on film

As an efficient and precise coating equipment, the heated squeegee coater shows significant advantages in the process of coating the surface of film materials with UV adhesive. In this paper, we will discuss the characteristics and value of this technology in detail from the aspects of working principle, practical application and precautions.

1. The working characteristics of the heating scraper coating machine

The core advantages of the heated doctor blade coater are its precise control of slurry flow and high-precision coating capabilities:

Heating control - the equipment adjusts the viscosity of the UV adhesive through the heating system to achieve the appropriate flow range. This not only ensures good spreadability of the slurry on the film surface, but also avoids coating failures due to improper temperatures.

Doctor Blade Process – Precise control of coating thickness is achieved using doctor blade technology, which is suitable for the formation of a uniform and dense UV adhesive layer on the film.

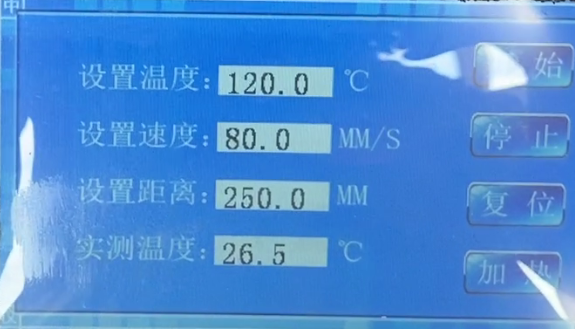

When using a heated squeegee coater to coat UV glue on the film, it is necessary to adjust the temperature (usually 80~120°C) to reduce the viscosity of the glue, and set the squeegee gap (such as 100~500μm) and coating speed (0.1~100mm/min) to control the film thickness to ensure that the substrate (such as PET) is clean and flat. After coating, it is cured with UV lamp (365/395nm, energy 300~1000mJ/cm²) to avoid sagging. The key attention is to glue deaeration, scraper flatness and curing parameter matching, which is suitable for the preparation of optical coatings, flexible electronics and other samples.

Second, the practical application of UV glue for film coating

Optical film manufacturing

Coating optical films with UV adhesive can form a protective layer or a functional coating (e.g. anti-reflective layer). The heated squeegee applicator guarantees a high uniformity of the coating and thus improves the optical properties.

Processing of packaging materials

For film packaging materials that require waterproof and oil-repellent functions, UV adhesives are often used for surface coating. With heated doctor blade technology, the coating can be completed quickly and the cure is efficient.

Electronic component packaging

Applying UV adhesive to the surface of a flexible circuit board or thin-film sensor can provide excellent protection. The high accuracy of the equipment ensures that the coating thickness is consistent and does not affect the electrical properties of the components.

3. Precautions for use

Substrate pretreatment

Ensure that the surface of the film is clean and free of stains, and if necessary, sanding or cleaning is carried out to improve the adhesion of the UV adhesive to the substrate.

Temperature control

UV adhesives are temperature sensitive, and the temperature control range of the heating system needs to be adjusted according to their performance parameters. Avoid excessive temperatures that cause film deformation or degradation of UV adhesive properties.

Coating uniformity check

Regularly use a Thickness Gauge to check the thickness of the coating film to ensure that it meets the process requirements.

The application of the heated squeegee coating machine to coat the film with UV glue shows the characteristics of high efficiency and high quality. Through precise temperature control and squeegee technology, the equipment can meet the coating needs of different scenarios, and is widely used in optics, packaging and electronics. Correct operation and optimized parameter settings will help to improve production efficiency and product quality.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2Using the drawdown blade Automatic Film Applicator to prepare Resin on Release Paper

- 3Advantages of drawdown blade method in preparation of perovskite solar cells

- 4Bar & casting knife heating Film Applicator Application of Water Treatment Film on Non-woven Fabric

- 5Study on Experimental Technique of Scraper Automatic Film Applicator Coating Adhesive on Film

- 6Fuel cell doctor blade Film Applicator: Working Principle and Application

- 7Application of Doctor blade Film Applicator in prepative foam coatings

- 8Laboratory Coating Machine Case | Sewage Treatment Flat Membrane/Vinylidene Fluoride PVDF Preparation

- 9Scraper film coater can be used to prepare modified polyolefinic diaphragm on PP film