Scraping machine selection case: film substrate large size high accuracy scraping solution

Background of customer needs

A material laboratory needs to carry out scraping experiments on a batch of thin film substrates, and the specific parameters are as follows:

1) Base material size: length 60~100cm, width 30cm

2) Single scraping length: sometimes up to 1 meter

3) The sample processing method requires that it cannot be rewinded

4) Coating film thickness: 1000 microns (1mm), high precision is required

Analysis of technical difficulties

1) Large-scale scraping challenge: Scraping lengths of up to 1 meter far exceed the working range of conventional laboratory coaters

2) Substrate fixing problem: The film substrate is light and thin, and it is difficult to ensure the flatness of the traditional clamping method

3) Thickness control accuracy: 1000 microns thick coating film requires the equipment to adopt high-precision coating equipment, and the equipment has high stability

4) Sample does not wind: excludes the possibility of conventional roll-to-roll coating equipment

solution

Equipment selection suggestions

After technical analysis, Nanbeichao Technology recommended a customized sheet coating machine solution for the customer, mainly based on the following considerations:

Advantages of sheet coating machine:

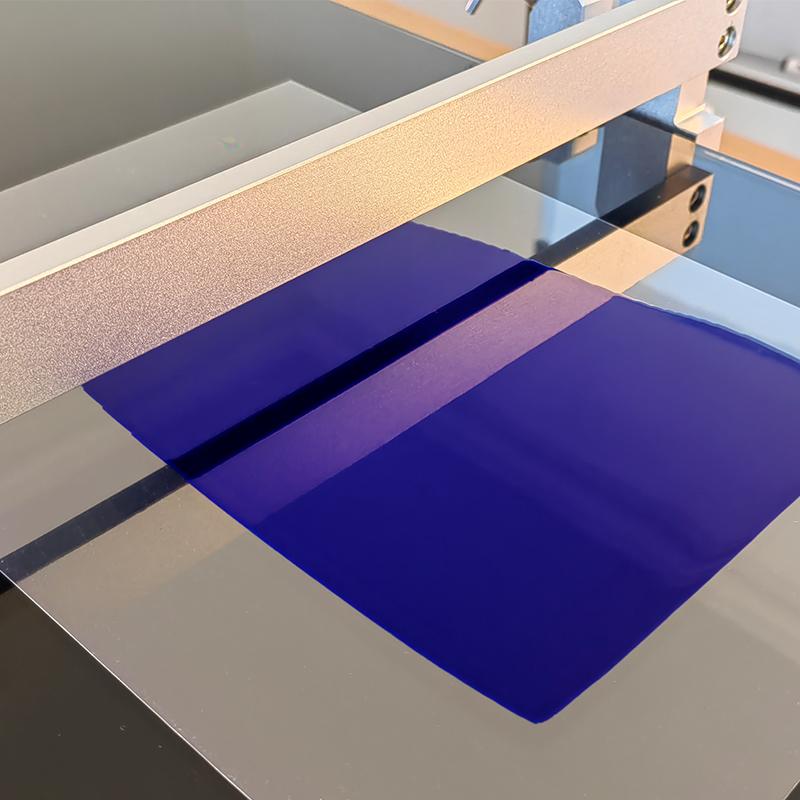

The working method of fixing the substrate and moving the scraper avoids dynamic interference

It is especially suitable for single-shot, large-size, high-precision scraping experiments

The restriction that the sample cannot be rewound can be resolved can be addressed

Vacuum Adsorption System:

Vacuum adsorption platform specifically designed for thin film substrates

Ensure that the large area of the film remains completely flat during the scraping process

Eliminate edge warpage that can occur with traditional mechanical clamping

Customized design:

The size of the working table is customized to 100cm×40cm (to meet the requirements of 1 meter scraping length)

The thickened platform structure ensures stability when working on large sizes

High-precision scraper/wire rod coating system to meet the requirements of 1000 micron thick coating

Alternatives evaluation

The customer had considered using a coil coater, but there were obvious deficiencies after analysis:

1) The coil coating machine adopts the method of "cutter head fixation and base film movement".

2) Dynamic operation is easy to produce vibration interference

3) It is not conducive to the precision control of monolithic scraping

4) Unable to meet the basic requirements of "sample not rewinding".

Key points of equipment customization

The customized solutions designed by Nanbeichao Technology for customers include the following key features:

Floor-mounted structure design:

The overall height is optimized for manual operator comfort

The reinforced base eliminates vibrations that can occur with large workbenches

Clamshell blade design

The color LCD touch screen controls the adjustment of coating length and speed

Precision Scraper System:

Big brand differential regulators

High-precision micron-level thickness adjustment device

Optional scrapers with special materials (for different slurry characteristics)

Extended Feature Reservation:

Heating platform can be upgraded

An automatic feeding system can be retrofitted

Compatible with a wide range of thickness measuring device interfaces

Ease of operation:

Summary of selection suggestions

For similar large-size, high-precision scraping needs, it is recommended to prioritize the following factors:

Substrate properties (especially flatness requirements)

The maximum size required for a single scrape

Thickness control accuracy requirements

Sample post-processing method (whether it needs to be rewound)

Possible future experimental expansion needs

As can be seen from this case, customized coating equipment for special experimental needs can often provide more accurate solutions than standard models. The technical support team of Nanbeichao can provide professional coating machine selection and customization suggestions according to specific experimental conditions.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Application of Film Applicator in PEM Research and Preparation

- 7Application of Film Applicator in PVDF-HFP Material Research

- 8Application of Film Applicator in Cosmetic Base Body

- 9Application of Automatic Film Applicator in preparing fluorescent diaphragm