Application and selection of laboratory coater in PDMS thin film prepative

introduction

Polydimethylsiloxane (PDMS) films are widely used in microfluidic chips, flexible electronics, biomedical sensors and other fields due to their excellent flexibility, optical transparency, chemical stability and biocompatibility. However, the preparation of PDMS films is extremely demanding on the coating process, and the uniformity, thickness control and surface quality of the film directly affect the performance of the final product. Therefore, choosing the right lab coater is crucial. In this paper, we will discuss the selection points and application significance of the coating machine in PDMS film preparation, and recommend the vacuum adsorption coating machine of Huinuo intelligent wire rod scraper as a solution.

1. The key requirements for coating machines for PDMS film preparation

The preparation of PDMS films typically involves the following steps:

1) PDMS prepolymer mixing (base glue mixed in proportion to hardener, e.g. 10:1)

2) Degassing treatment (removes air bubbles in the mixture to prevent film defects)

3) Coating film formation (uniform coating on the surface of the substrate)

4) Thermal curing (60~80°C curing molding)

Among them, the coating process has the most stringent requirements for the equipment, which needs to meet:

High-precision thickness control (micron-level adjustment to ensure film uniformity)

Bubble-free coating (avoids holes or defects in the film after curing)

Controllable coating speed (affects leveling and surface roughness)

Substrate adaptability (compatible with glass, silicon wafer, PET and other substrates)

Second, the selection of laboratory coating machine points

For PDMS films, wire rod and blade coating is a common method due to its high accuracy and wide range of adjustable thicknesses, making it suitable for scientific research and low-volume production.

Key selection parameters

Coating accuracy: micron-level adjustment (such as 1~500μm) is required.

Vacuum adsorption function: fix the substrate to prevent the substrate from moving during the coating process and improve uniformity.

Temperature control system: The viscosity of PDMS is affected by temperature, and the constant temperature coating can improve consistency.

Automatic control: digital speed regulation and other functions reduce human error.

Compatibility: It can be adapted to different size substrates (such as silicon wafers, glass wafers, etc.).

3. The advantages of Huinuo intelligent wire rod scraper vacuum adsorption coating machine

For the preparation needs of PDMS films, Huinuo intelligent wire rod scraper vacuum adsorption coating machine provides a suitable solution, and its core advantages include:

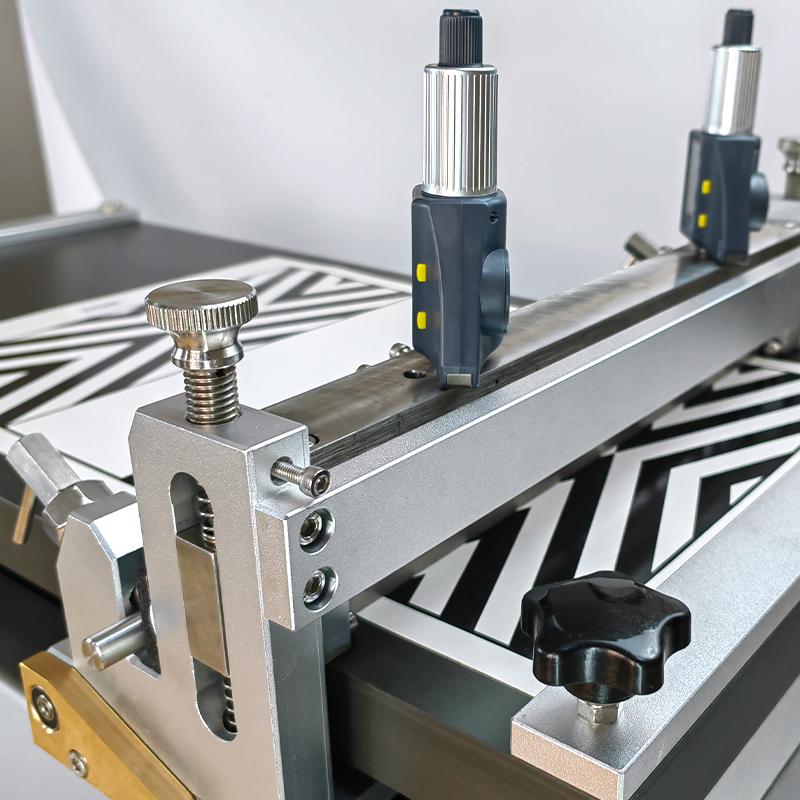

1. High-precision scraper coating system

With precision fine-tuning squeegee, film coating in the range of 1~5000μm can be realized, meeting different needs from ultra-thin (microfluidic chips) to thicker (flexible substrates).

2. Vacuum adsorption substrate fixation

The built-in vacuum adsorption table ensures that the substrate (such as glass, silicon wafer) has no displacement during the coating process and avoids the problem of uneven edges.

Particularly suitable for flexible substrates (e.g. PET) to prevent the substrate from warping during coating.

3. Intelligent temperature control and online monitoring

Optional heating substrate (RT~150°C), suitable for PDMS pre-curing or high temperature coating process.

4. User-friendly design

Touch screen control, preset PDMS coating process parameters, reduce manual adjustment time.

Modular design, can be upgraded to automatic feeding or multi-coat coating mode.

Fourth, the application case and industry significance

1. Microfluidic chip manufacturing

The 100~300μm PDMS film is prepared by the Huinuo intelligent coating machine, and the microchannel is formed by photolithography or molding method, which is used for biological detection, organ-on-a-chip, etc.

Vacuum adsorption ensures uniform application and reduces the risk of leakage during subsequent bonding.

2. Flexible electronics

Coated with ultra-thin PDMS substrates of 50 μm or less for stretchable circuits, flexible sensors, etc.

High-precision control avoids device failure caused by uneven stress in the film.

3. Biomedical coatings

Homogeneous PDMS films can be used for cell culture substrates, etc., and the repeatability of the coater is crucial.

V. Conclusions

The preparation quality of PDMS film directly affects its application effect in the fields of microfluidics and flexible electronics, and the selection of laboratory coating machine is the key influencing factor. With the advantages of high-precision scraper, vacuum adsorption fixation, and temperature control integration, Huinuo intelligent wire rod scraper vacuum adsorption coating machine has become a reliable choice for PDMS film preparation, which can significantly improve the process stability and efficiency of scientific research and industrialization.

(If you need detailed parameters or trial of the equipment, you can contact the technical support of Nanbeichao.) )

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body