Application Technology of Laboratory Film Applicator in Dielectric Thin Film

introduction

In the field of modern electronic technology, dielectric material films are widely used in key components such as capacitors, integrated circuits, and sensors due to their unique electrical properties. Its performance directly affects the process of miniaturization and high performance of electronic equipment. As the core equipment for the preparation of high-quality dielectric material films, the laboratory coating machine can effectively control the microstructure and macroscopic properties of the film through precise control of the coating process, and provide key technical support for the research and development of dielectric material films.

How the laboratory film coater works

There are various types of laboratory coating machines, such as Spin Coaters, squeegee coaters, spraying machines, etc., and the working principles of each equipment are different. When the Spin Coater is working, the substrate is fixed on a high-speed rotating turntable, and the dielectric material solution is added dropwise to the center of the substrate, and under the action of centrifugal force, the solution is rapidly spread to the edge, and the solvent volatilizes to form a uniform film on the surface of the substrate. The squeegee coater adjusts the gap between the scraper and the substrate to evenly scrape and coat the dielectric material slurry on the substrate, and then dry and solidify to form a thin film. The sprayer atomizes the dielectric material solution with the help of high-pressure gas and sprays it evenly on the surface of the substrate to build a thin film structure.

Dielectric material film characteristics and requirements for coating film process

Dielectric material films have the characteristics of high dielectric constant, low dielectric loss, and good insulation properties. Different application scenarios have different requirements for the characteristics of dielectric material films, for example, in high energy storage density capacitors, the film is expected to have high dielectric constant and low dielectric loss; In the application of integrated circuit insulation layer, more emphasis is placed on the insulation and flatness of the film. This requires a coating process that can precisely control the film thickness, uniformity and microstructure. The thickness of the film should be strictly controlled at the nanometer to micron level, and the thickness deviation should be very small to ensure stable electrical performance. In terms of uniformity, the film is required to have no thickness fluctuations and no defects in a large area; In terms of microstructure, it is necessary to adjust the crystallinity and orientation of the material to ensure that the film has good dielectric properties.

The application process of film coater in the preparation of dielectric material films

Preparation of materials

Select suitable dielectric materials, such as barium titanate (BaTiO₃) of ceramics and polyimide (PI) of polymers, and make them into homogeneous solutions or slurries. Solution/slurry concentration, solvent type, additives, etc. have a significant impact on the performance of the film. Taking BaTiO₃ as an example, high concentration can easily lead to uneven film thickness and agglomeration. If the concentration is too low, it is difficult to form a film. The solvent evaporation rate affects the film drying process, which in turn affects the microstructure. Additives improve the rheological properties of the material and contribute to the uniformity of the coating film.

Equipment commissioning

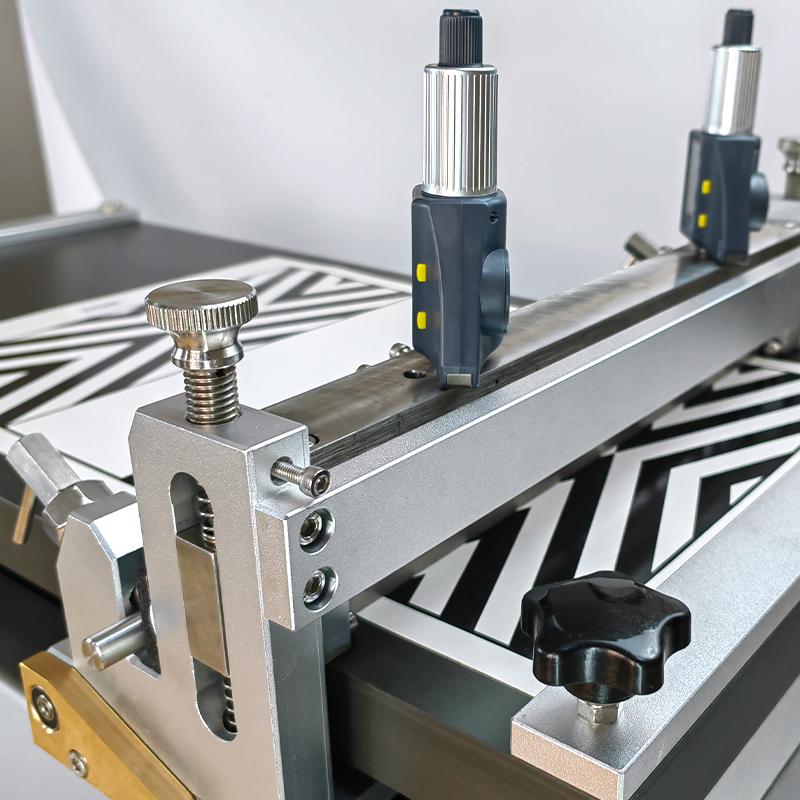

According to the material characteristics and target film parameters, the key parameters of the coating machine are debugged. For the Spin Coater, the speed determines the thickness of the film, the higher the speed, the thinner the film, and the acceleration of the solution drops needs to be adjusted to ensure that the solution is fully spread without exceeding. The squeegee coater needs to accurately adjust the gap between the scraper and the substrate, usually in tens of microns to hundreds of microns, and also needs to control the scraping speed, which is easy to produce streaks if the speed is too fast, and low efficiency if it is too slow. The spraying machine needs to adjust the spraying pressure and the distance between the nozzle and the substrate, the pressure affects the atomization effect, and the distance determines the uniformity of film deposition.

Coating process

Place the prepared substrate on the coating machine table and start the machine for coating. In the process of spin coating, the solution is rapidly spread under centrifugal force to form a film, and it is necessary to pay attention to the influence of the acceleration and deceleration of the turntable on the quality of the film to avoid thickening of the edges or uneven film spun. When scraping, the scraper moves at a constant speed to ensure that the slurry evenly covers the substrate and prevents the slurry from drying out or mixing with impurities in the process. When spraying, the nozzle scans the substrate according to the set path to ensure the consistency of the film thickness, and at the same time controls the ambient humidity and temperature to prevent the solvent from volatilizing too quickly or too slowly and affecting the quality of the film.

Follow-up processing

After the coating is completed, the film needs to be dried and cured. In the drying process, the solvent in the film is removed, and the temperature and time control are extremely critical, as too high a temperature may lead to cracking and deformation of the film. Solvent residue for too short a time affects the performance of the film. Curing makes the microstructure of the film stable, and for thermosetting polymer films, it needs to be kept at a specific temperature for a certain time to complete the cross-linking reaction; For ceramic films, high-temperature sintering may be required to promote crystallization and improve dielectric properties.

Effect of the coating process on the properties of dielectric films

Effect of film thickness and uniformity

The thickness of the film is directly related to the dielectric constant and capacitance value, and the dielectric properties can be precisely controlled by precise control of the thickness. The film with poor uniformity has a concentrated electric field at a thick place, which is easy to cause partial discharge and increase dielectric loss. The insulation performance of thin places is reduced, which affects the reliability of the equipment. Studies have shown that the film thickness deviation is controlled within ±5%, which can ensure stable dielectric properties. For example, when preparing PI film for flexible circuit board insulation, the uniform film thickness makes the circuit board signal transmission more stable and reduces signal attenuation.

Microstructural influences

The coating process affects the microstructure of the dielectric material film, which in turn determines its properties. Taking BaTiO₃ films as an example, the spin coating process combined with appropriate annealing treatment can obtain films with uniform grain size and consistent orientation, which significantly improves the dielectric constant and breakdown strength. If the scraping and spraying process is properly controlled, the microstructure of the film can also be controlled, for example, by adjusting the rheological properties and spraying parameters of the slurry, the film can form a porous structure, which can be used to prepare a film with low dielectric constant and high insulation performance to meet the needs of high-frequency circuits for low-loss media.

Application examples

Electronic capacitor field

In the preparation of the dielectric separator film between the electrode and the electrolyte of the supercapacitor, a polymer solution containing nanoscale ceramic particles is coated on the surface of the electrode material by a Spin Coater, and the dielectric film with high dielectric constant and good flexibility is formed after curing. The film effectively improves the energy density and charging and discharging efficiency of capacitors, and greatly increases the application potential of supercapacitors in the fields of fast charging of electric vehicles and energy storage for smart grids.

Integrated circuit insulation

In the manufacture of integrated circuits, the improved polyimide slurry is evenly coated on the surface of the silicon wafer by a squeegee coater, and cured at high temperature to form an insulating dielectric film. This film has very low dielectric loss and good flatness, which meets the needs of high-density inter-wiring insulation in the chip, reduces signal crosstalk, improves the operation speed and stability of the chip, and promotes the development of integrated circuits in the direction of higher integration and lower power consumption.

conclusion

Laboratory coaters play a key role in the preparation of dielectric films, and by precisely regulating the coating process, they can produce dielectric films with excellent performance that meet the needs of different applications. With the continuous improvement of electronic technology requirements for dielectric material film performance, the coating machine equipment and process will continue to innovate and develop, provide solid technical support for the research and development and application of new dielectric materials, and help the electronic information industry to a new height

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 4Application and selection of laboratory coater in PDMS thin film prepative

- 5Scraping machine selection case: film substrate large size high accuracy scraping solution

- 6Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body