Hypertherm HLX-J and HLX-S Tensile machine

1. Features

HLX-J and HLX-S spiral dynamometer workbenches are designed to cooperate with imported and domestic pointer and digital display push-pull dynamometers (0-500N), and are suitable for pulling in various industries and scientific research institutions. Pressure load, insertion force, destructive test, etc. The workbench has the characteristics of stable operation, simple operation, easy movement, easy installation, vertical and horizontal dual-purpose, etc.

2. Installation

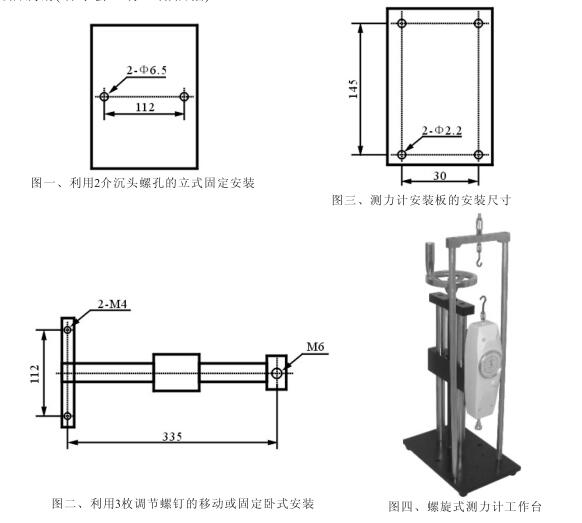

(1) Please refer to the dimensions shown in the figure when installing.

a. Vertical fixed installation using two φ6.5 countersunk holes on the bottom plate (see Figure 1)

b. Use the two M4 screw holes on the side of the bottom plate and the M6 screw holes on the positioning plate to move or fix the horizontal installation

Install (see picture 2)

c. Installation dimensions of the dynamometer mounting plate (see Figure 3)

d. Spiral dynamometer workbench (see Figure 4)

(2) Install the M6×60 stud bolts, M6 knurled nuts and hooks in the accessory bag to the horizontal

Take it on (as shown in Figure 4).

(3) Remove the 4 pieces of M3×10 screws on the back cover of the dynamometer, and use the 4 pieces of M3×14 screws in the accessory bag

Nails, and install the dynamometer on the workbench (see Figure 3 for installation dimensions).

3. Model specification

(1) Maximum stroke: 200mm

(2) Maximum load: 500N

(3) Dimensions: 235×155×490mm

(4) Net weight: 2.5kg

4. Test

This workbench can carry out testing work in two directions of tension and compression. According to the characteristics of the product to be tested,

Place it in a suitable place on the workbench. Rotate the hand wheel on the workbench, the meter will be smoothly

Move up and down to complete the test work.

5. Maintenance

1. Pay attention to keep all parts of the workbench clean.

2. When you feel that the movement of the workbench is stagnant and inflexible, please add a little

Oil lubrication (there is an oil storage tank on the copper guide bush).

- 1Tensile machine application in various industries

- 2Technical analysis of key parameters of Tensile machine: Scientific selection from force measurement accuracy to Power system

- 3Tensile machine purchasing guide [dry version]

- 4Talking about the performance test of epoxy resin film coated on PET

- 5ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 6Common problems and solutions in tensile testing

- 7What is tensile strength testing and which products can be tested?

- 8Factors Affecting the Performance and Accuracy of Tensile Testing Machines

- 9Classification of Tensile Testing Machines