Application of laboratory coater in LED fluorescent film Spreader

In the current era of LED technology, LED phosphor films are a key component, and the coating quality plays a decisive role in the LED luminescence effect. Recently, we received an inquiry from a customer who needed to coat LED fluorescent films with a film thickness of 120 microns, a film substrate, and a high sample viscosity. This puts forward extremely strict requirements for the selection of laboratory coating machines. This article will focus on this need and delve into the application selection of laboratory coating machines for LED fluorescent film coating.

LED fluorescent film coating process requirements analysis

The coating of LED phosphor films requires highly precise thickness control to ensure uniform distribution of fluorescent materials, resulting in stable and consistent luminous effects. For this customer's needs, the 120 micron coating thickness needs to be uniform across the entire substrate film, and even small thickness deviations can cause differences in LED luminous intensity and affect product quality. In addition, the substrate is a thin film, which means that it needs to be operated gently and steadily during the coating process to avoid damage or deformation of the film due to mechanical stress. At the same time, the viscosity of the sample is very high, which brings great challenges to the coating process, and it is difficult to spread the high-viscosity sample evenly with ordinary coating methods.

Overview of the working principle and characteristics of laboratory coating machines

Common coating principles

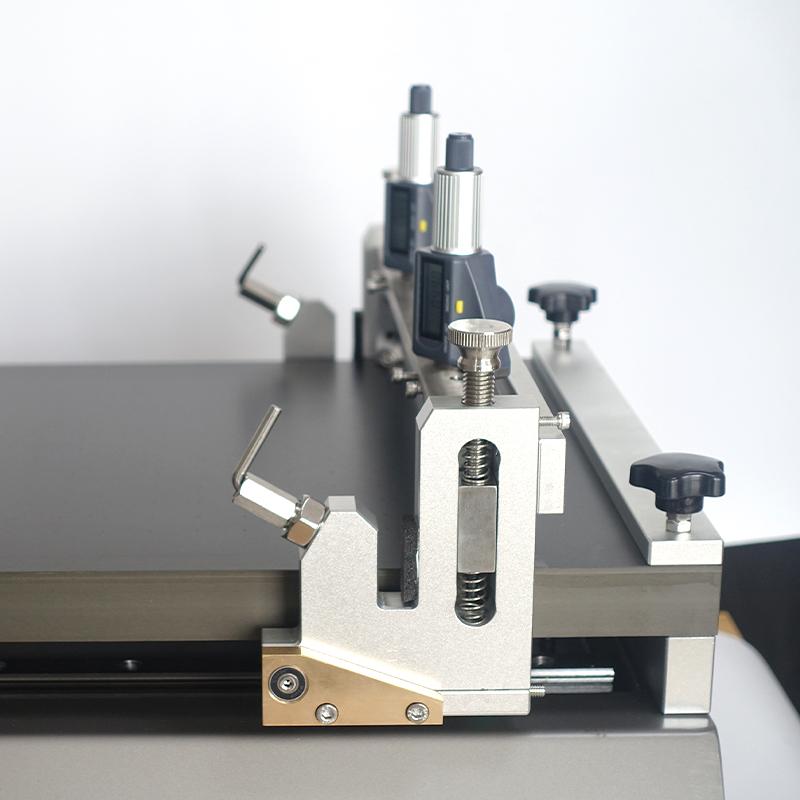

1. Scraper coating:The scraper blade is used to scrape off excess paint, and the coating thickness is controlled by adjusting the gap between the scraper and the substrate surface. This method is relatively easy to operate, the equipment cost is low, and for high-viscosity samples, if the appropriate scraper type and parameters are selected, better coating results can also be achieved.

2. Roller coating:It is divided into forward coating and reverse coating, and the coating is transferred to the substrate by the rotation of the roller. Roller coating has a certain applicability for high-viscosity coatings, and can use the extrusion action of rollers to make the coating better spread. Among them, reverse roller coating is better when handling high-viscosity materials, and the amount of coating can be accurately controlled by adjusting the pressure and speed between the rollers.

3. Slit coating:The coating is evenly extruded through the slit under pressure and applied to the substrate. This method can achieve high-precision coating thickness control, especially suitable for coating high-viscosity fluids, and can accurately adjust the coating thickness by adjusting the slit width, feed pressure, and coating speed.

4. Spraying:Spray the paint onto the surface of the substrate. Although spraying can achieve rapid coating, it is difficult to atomize for high-viscosity samples and does not allow for precise control of coating thickness, limiting its application in LED fluorescent film coating, which requires precise coating thickness.

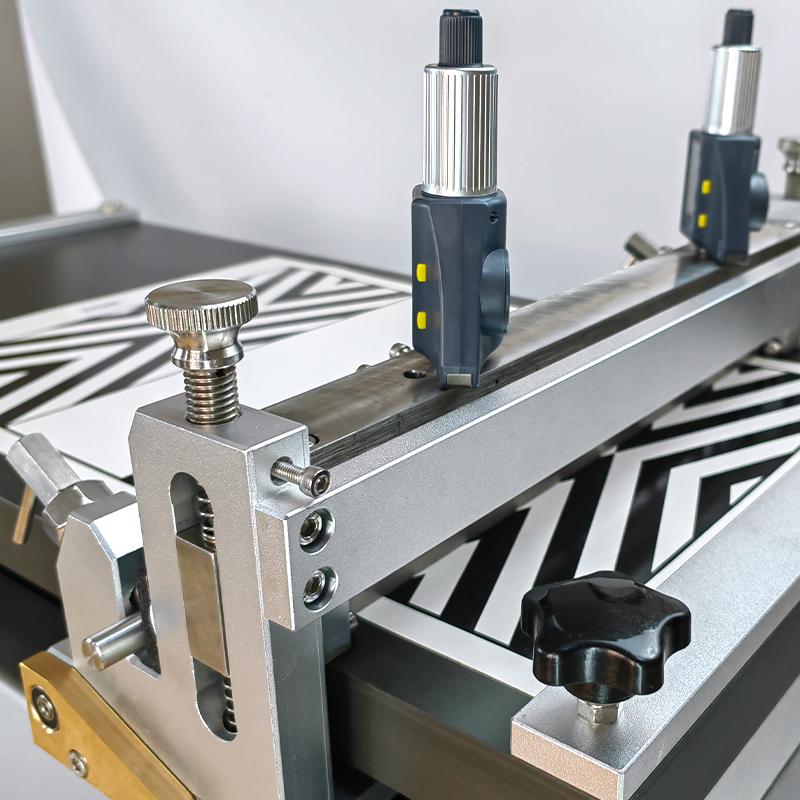

Key system features of the coating machine

1. Coating system:As a core component, its design and performance are directly related to the quality of the coating. A good coating system should be able to accommodate different viscosities of coatings and have precise coating volume adjustments.

2. Substrate transfer system:It is necessary to ensure that the substrate film passes smoothly and uniformly through the coating area to avoid jitter or shift, which can lead to uneven coating thickness. At the same time, it should have good tension control capabilities to prevent the film from deforming due to improper tension during transmission.

3. Control system:The modern coating machine control system can accurately adjust the coating speed, temperature, pressure, and other parameters, and has real-time monitoring and feedback functions to ensure the stability and consistency of the entire coating process.

Laboratory coater selection recommendations for high viscosity samples

Based on the above analysis of the requirements of the LED fluorescent film coating process and the working principle and characteristics of the laboratory coating machine, the following laboratory coating machines are more suitable for the customer's high-viscosity samples.

Squeegee coater

Advantage: For high-viscosity samples, squeegee coaters are not completely unsuitable. When the viscosity of the sample is high but still has a certain fluidity, choosing a scraper with appropriate hardness (such as a polyurethane scraper) and reasonably adjusting the scraper angle and coating speed can effectively reduce the resistance of the scraper and reduce wear. At the same time, by precisely adjusting the gap between the scraper and the substrate, it can meet the requirements of 120 micron coating film thickness, and the equipment cost is low, easy to operate, and suitable for the coating test of small batches of samples in the laboratory.

Slit coater

Advantages: Slit coaters offer significant advantages in handling high-viscosity samples. By precisely controlling the slit width and feed pressure, it can evenly extrude and coat high-viscosity LED fluorescent film samples onto the film substrate, which is well suited to meet the precise control requirements of 120 micron coating thickness. At the same time, because the coating is directly extruded under pressure, there is no need to overcome large resistance like scraper coating, so the wear of the equipment is small, and the uniformity and stability of the coating can be guaranteed.

Reverse roller coating machine

Advantages: The reverse roller coater has good adaptability to high viscosity coatings. The rollers rotate in the opposite direction to apply a large extrusion force to the highly viscous LED fluorescent film sample, allowing it to be evenly transferred to the film substrate. And by flexibly adjusting the speed and pressure of the roller, the coating amount can be accurately controlled to meet the needs of different thicknesses of coating film. In addition, the structure of the reverse roller coater is relatively simple and the maintenance cost is low.

Other factors to consider when selecting a type

Equipment accuracy and stability

Precision: When selecting a lab coater, it's essential to ensure that its accuracy can meet the requirements of a 120-micron coating film thickness. High-precision coating machines can effectively reduce the defective rate of products and improve production efficiency. For example, some advanced coating machines can achieve an accuracy of up to ±1 micron, providing reliable guarantee for LED fluorescent film coating.

Stability: Stable equipment operation is the key to ensuring the consistency of coating quality. During long-term operation, the parameters of the equipment should be stable to avoid fluctuations, otherwise it will lead to unstable coating thickness and affect the performance of LED fluorescent film.

Ease of operation and maintenance costs

Ease of operation: Coating machines that are easy to operate and easy to use can improve work efficiency and reduce operator training costs. Modern coaters are often equipped with intuitive HMIs, and the operator can easily set and adjust various coating parameters via the touch screen.

Maintenance cost: The maintenance cost of equipment is also one of the key factors to consider when selecting. A coating machine with simple structure and strong versatility of parts should be chosen, so that in the event of equipment failure, it can be repaired quickly and the maintenance cost is low. At the same time, the wearing parts of the equipment should be easily available to reduce the time cost of maintenance.

summary

In the world of LED fluorescent film coating, especially when dealing with high-viscosity samples and stringent film thickness requirements, the right choice of laboratory coater is crucial. Squeegee coaters are suitable for high viscosity samples under specific conditions, while slit coaters and reverse roller coaters are also excellent solutions. During the actual selection process, it is necessary to comprehensively consider various factors such as the specific characteristics of the sample, laboratory budget, and production needs to ensure that the selected equipment can operate efficiently and stably, providing strong support for the high-quality production of LED phosphor films.

- 1NVP anode film FAQ and solution

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of Automatic Film Applicator in preparing fluorescent diaphragm

- 5Brief analysis of the preparation technology of ionic liquid polymer composite electrolysis and anode pole piece

- 6Experimental application of water-based paints on film laminating paper by laboratory coater

- 7Experimental coater application case video of liquid silica gel on release paper

- 8Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

- 9Application Case of Automatic Film Applicator Coating Metal Powder Solution on Titanium Fiber Felt [With Video]