Hypertherm HCL Side Swing Test Bench Operating Instructions

side rocking test bench

The HCL manual vertical side-sway test bench is specially equipped for push-pull force gauges at home and abroad, and can be combined into test machines for different purposes, suitable for various tests such as insertion force, pressing force, and destruction test. While displaying the force value, a digital display scale can also be installed to display the displacement, and a comparative test of different workpieces under the same displacement can be carried out.

1. Features

◆The base of the machine is large and stable, suitable for indoor desktop testing.

◆The trapezoidal screw rotates, and the side handwheel is loaded, so the operation is simple and stable.

◆The standard mobile platform of the base can realize left and right, forward and backward movement, convenient and accurate clamping.

◆The machine can be installed on a table (table) to make the frame more stable.

◆ Equipped with a digital display scale, which can collect travel data (HCS) at any time.

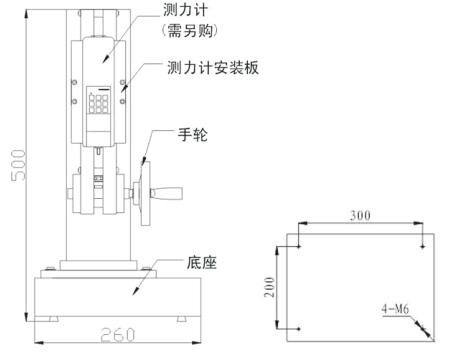

2. Structural diagram

3. Installation method of machine table and push-pull force gauge

(1) Use an M4 wrench to loosen the four M4×15 socket head cap screws on the dynamometer mounting plate.

open and remove the dynamometer mounting plate. )

(2) To install the HF series (digital push-pull force gauge) push-pull gauge, use the M4 hexagon wrench to pass the four M4 × 10 hexagon socket screws in the accessory bag through the 90×40 hole on the dynamometer mounting plate Screw into the four M4 threaded holes of the dynamometer, install the dynamometer on the mounting plate of the dynamometer, or use a cross-fiber knife to pass four M3×10 cross-recessed pan head screws in the accessory bag through the measuring Inside the dynamometer, mount the dynamometer to the dynamometer mounting plate. The 145×30 holes on the mounting plate are screwed into the four M3 threaded holes of the dynamometer.

(3) Install the push-pull force gauge of NK series (pointer push-pull gauge), remove it with Phillips screws, remove the 4 pieces of M3×10 screws in the accessory bag, and remove the 4 pieces of M3×14 screws in the accessory bag Cross-recessed screws pass through the 145×30 mounting holes on the dynamometer mounting plate, and screw into the four M3 threaded holes on the back cover of the dynamometer (remove the threaded holes for the M3×10 screws).

(4) After installing the push-pull force gauge, use the M4 inner hexagon wrench to reinstall the force gauge mounting plate.

Install on the rack. According to the characteristics of the sample to be tested, install or place the machine in a suitable position on the workbench. Rotate the hand wheel on the side of the test stand, and the dynamometer can move up and down smoothly to complete the test work.

4. Daily maintenance and maintenance

1. Do not use it with overload, the rated load of this rack is 500N.

2. Pay attention to daily work and keep all parts of the machine clean.

3. When the machine is running sluggishly and inflexibly during use, please add a little oil to the oil filling holes on the bearing seats on both sides of the machine for lubrication. When the machine breaks down, please contact the manufacturer (do not disassemble or repair without authorization).

- 1Hypertherm HG digital push-pull force meter calibration method

- 2Hypertherm HG Force Gauge calibrating method

- 3Hypertherm NK Series Pointer Force Gauge Instructions

- 4Installation Instructions for HLX Series Spiral Force Gauge Benches

- 5Hypertherm HG Digital Display Force Gauge Operating Instructions

- 6Hypertherm HF Digital Display Force Gauge Operation Instructions Detailed Explanation

- 7Hypertherm HDD, HDE, HDT series Tensile machine operating instructions

- 8Hypertherm Pointer Force Gauge Instructions

- 9Hypertherm HST-J Hand Pressed Tension and Compression Test Bench Description