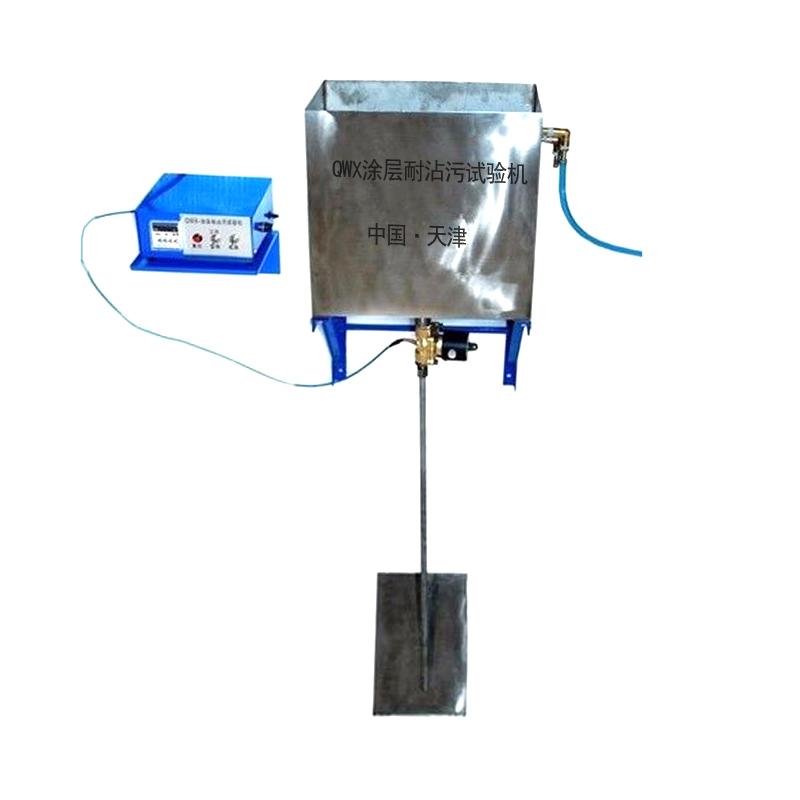

Stain resistance Tester: professional equipment and test principle for material anti-pollution performance testing

Introduction: The importance of stain resistance

In the field of materials science and engineering, stain resistance is a key indicator of the resistance of a material surface to contamination. Whether it is architectural coatings, automotive coatings, textiles, or surface materials such as plastics and metals, they will be affected by dust, oil stains, liquid pollutants, etc. during actual use, resulting in reduced aesthetics, increased cleaning difficulty, and even affecting service life.

As a professional testing equipment, the stain resistance Tester provides a scientific basis for product development, quality control and industry standard compliance verification by simulating the pollution process in the real environment and quantitatively evaluating the anti-fouling ability of materials. This article will introduce in detail the definition, application scenarios, testing principles and technological development of stain resistance Testers to help industry practitioners deeply understand their importance.

1. Definition and application scenarios of stain resistance Tester

1. What is a stain resistance Tester?

The stain resistance Tester is a professional testing equipment used to evaluate the anti-fouling ability of the surface of materials, which is widely used in coatings, building exterior wall coatings, automotive interiors, textiles, plastics, metal coatings and other fields. Its core function is to quantify the stain resistance of material surfaces through standardized pollution simulation + cleaning testing, helping manufacturers optimize material formulations (such as enhancing hydrophobicity) and improve processes, thereby improving product durability and user experience.

2. Main application areas

• Construction industry: Testing the anti-pollution ability of exterior wall coatings, tiles, stone, etc. when exposed to dust, acid rain, oil and other environments for a long time.

• Automotive Industry: Evaluating the resistance of automotive paints and interior materials to common contaminants such as fingerprints, beverage stains, and oil stains.

• Textile industry: Test the easy-to-clean properties of fabrics in daily wear, such as oil, stain, and water repellent.

• Coating research and development: Verify that the stain resistance of the new formulation complies with international standards such as GB/T, ASTM, and ISO.

• Plastics and Metals: Testing the anti-contamination ability of plastic products and metal coatings in industrial environments.

2. The test principle of the stain resistance Tester

The test logic of the stain resistance Tester is based on the closed-loop process of "pollution-stability-cleaning-evaluation", simulating the real pollution scenario through the control variable method, and determining the stain resistance level of the material through quantitative indicators (such as reflectance change and stain residue). The testing process can be divided into four key stages:

1. Pollution simulation and application

First, select a contamination medium (such as carbon black suspension, edible oil, fly ash solution, dust, etc.) that is close to the actual pollution source, and cover it evenly on the surface of the material to be tested by a precision coating system (such as rotating nozzles, scrapers, rollers).

• Contaminant type: Selected according to the material application scenario, such as fly ash aqueous solution specified in the GB/T 9780-2013 standard commonly used in architectural coatings, and artificial sweat or grease mixtures may be used in textiles.

• Coating method: Mechanical devices (such as spraying, scraping, soaking) are used to ensure that the stain acts on the sample surface at a constant pressure and speed, avoiding human error.

• Control variables: Contaminant concentration, adhesion, and coating uniformity directly affect the reproducibility of test results.

2. Pollution exposure and stabilization

After the stain is applied, the sample is subjected to specific environmental conditions (temperature, humidity) for a period of time (usually 24 hours) to allow the contaminants to fully penetrate or adhere to the surface of the material.

• Environmental Control: High temperatures and humidity may accelerate the curing of oily stains, and dry environments may lead to loose particle adhesion.

• Standard environment: usually requires 23°C±2°C, 50%±5% RH (such as GB/T standard), and some tests need to be carried out in a constant temperature and Humidity Chamber.

3. Cleaning process and effect evaluation

The cleaning phase simulates routine maintenance behavior, cleaning by mechanical force (brushing, rinsing) or chemical agents (detergents), and evaluates stain resistance.

(1) Cleaning method

• Mechanical cleaning: such as high-pressure water flow (0.1-0.5MPa), brushing (1-10 times/minute), soft cloth wiping, etc.

• Chemical cleaning: Simulate real-world cleaning scenarios with neutral cleaners.

(2) Evaluation method

• Optical performance changes: The difference in surface reflectance before and after cleaning is measured by a gloss meter or reflectance meter, and the smaller the reflectance drop, the better the stain resistance.

• Visual residue observation: Directly check if the stain has been completely removed or compare it to a standard color chart (e.g., ASTM D4828 grade 1-5).

• Color difference analysis: Use a Colorimeter to measure the color difference value (ΔE) before and after the test, the smaller the value, the stronger the anti-fouling ability.

3. The technical development and application value of the stain resistance Tester

1. Standardize the testing process

The design of the stain resistance Tester strictly follows international/industry standards, such as:

• CHINA: GB/T 9780 (Stain Resistance of Architectural Coatings)

• USA: ASTM D3359 (Coating Adhesion and Stain Resistance)

• Europe: ISO 4628 (Coating Aging and Contamination Assessment)

2. Automation and intelligence trends

Modern stain resistance Testers have automated features such as:

• Automatic application of contaminants (precise control of volume and uniformity)

• Intelligent adjustment of drying environment (temperature and humidity control)

• Programmatic cleaning and data logging (reduce human error and increase efficiency)

3. Application value

• Product development: guide coating formulation optimization (e.g., enhanced hydrophobicity, oil resistance).

• Quality Control: Ensure products meet industry standards and reduce customer complaint rates.

• Consumer benefits: Products certified for stain resistance testing often have a longer lifespan and lower maintenance costs.

Conclusion: The stain resistance Tester is a key tool for material property testing

Through scientific pollution simulation + accurate cleaning evaluation, the stain resistance Tester provides reliable material anti-fouling performance data for coatings, textiles, automobiles, construction and other industries. With the advancement of technology, modern stain resistance Testers are developing in the direction of automation, intelligence, and standardization, helping manufacturers improve product quality while providing consumers with more durable product choices.

For enterprises, stain resistance testing is not only a necessary part of quality control, but also an important embodiment of product competitiveness.