Torque Tester comprehensive analysis: Definition, core application and professional selection guide

1. Definition and working principle of Torque Tester

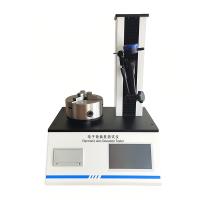

1. What is a Torque Tester?

A Torque Tester is a specialized device used to accurately measure torque (torsional moment) in a rotating or stationary state. Its core function is to convert mechanical torsional forces into readable electrical signals and visualize torque values in digital form through a data processing system. In the International System of Units, the unit of torque is the Newton-meter (N·m).

2. Core composition and working principle

Modern Torque Testers typically consist of the following key components:

• Torque sensor: the "heart" of the instrument, sensing torque changes through strain gauges, magnetoelastic effects and other technologies, and converting them into electrical signals.

• Signal conditioning module: Amplify and filter the original signal to eliminate environmental interference (such as electromagnetic noise and vibration) and improve data accuracy.

• Data acquisition and processing unit: A high-speed computing module based on a microprocessor that calculates torque values in real time and supports peak holding, statistical analysis, and other functions.

• Display and Interactive Terminal: Provides an intuitive digital/graphical interface that supports parameter setting, data storage, and result export.

According to the measurement object

Torque Testers are divided into two categories:

• Static Torque Tester: Suitable for low-speed or stationary scenarios such as bolt tightening torque and hand tool operation, with high measurement accuracy and strong anti-interference.

• Dynamic Torque Tester: Designed for high-speed rotating equipment (e.g., motors, engines) to capture instantaneous torque changes in real time, requiring high bandwidth and vibration resistance.

2. The core application areas of Torque Testers

Torque Testers are used in a wide range of industries, from precision manufacturing to everyday consumer goods, and their core value lies in ensuring product quality and process reliability through accurate measurements.

1. Quality control in the manufacturing industry

• Automotive industry: Detect the assembly torque of engine bolts, transmission gears, and chassis fasteners to ensure vehicle driving safety; The torque test of the motor of new energy vehicles directly affects the stability of power output.

• Mechanical Manufacturing: Verify the torque characteristics of transmission components (e.g., gearboxes, couplings) to optimize mechanical design and prevent overload failure.

• Fastener industry: Check whether the preload force of bolts and nuts meets the design standards to avoid loosening or overload fracture caused by insufficient torque.

2. Electronic and electrical equipment

• Electronic equipment assembly: calibrate the torque output of screwdrivers and electric screwdrivers to prevent damage to precision components such as mobile phone motherboards and computer chips due to improper tightening force.

• Battery manufacturing: Detect the tightening torque of battery module connectors to ensure the reliability of electrical contact and avoid the risk of short circuits or poor contact.

3. Aerospace and medical devices

• Aerospace: Measure the torque value of rocket engine turbine blades and aircraft structural parts to ensure reliability in extreme environments. Dynamic torque testing is used to simulate load changes in high-speed rotating components.

• Medical Devices: Detect the torque of surgical instruments and medical equipment connection parts to ensure operational accuracy and patient safety (e.g., dental drills, implant fixing screws).

4. Consumer Goods & Packaging Industry

• Food & Beverage: Test cap sealing torque to balance opening convenience with sealing to extend product shelf life.

• Cosmetics: Ensure that the torque of tube caps and stoppers meets hygienic standards to prevent leakage or contamination.

3. Professional selection guide for Torque Testers

Selecting a suitable Torque Tester requires comprehensive consideration of measurement needs, environmental conditions, and functional scalability, with the following key selection factors:

1. Measurement range and range utilization

• Clarify the minimum and maximum values of the torque to be measured, and give priority to instruments with a range covering the actual requirements (such as accuracy adaptation when the conventional measurement value is 20%-80% of the range).

• Multi-range or adjustable range design for mixed torque scenarios (e.g., simultaneous detection of small and large torque bolts).

2. Precision and resolution

• For high-precision scenarios (e.g., aerospace, medical devices), choose instruments ± 0.1% FS (full scale) or higher, and focus on resolution (minimum detectable torque change).

• For general industrial applications, such as general mechanical assembly, ± 1% FS accuracy is usually sufficient.

3. Dynamic characteristics and responsiveness

• Dynamic measurements focus on bandwidth (frequency response range) and sampling rate (in Hz), while high-speed rotation scenarios (e.g., motor instantaneous torque) require high sampling rates to capture transient changes.

• Anti-interference designs (e.g., electromagnetic shielding, vibration isolation) are essential for industrial sites.

4. Installation method and environmental adaptability

• Mounting type: Contact (built-in sensor) is suitable for stationary equipment, non-contact (such as optical/wireless sensor) is suitable for rotating parts or tight spaces.

• Protection level: In industrial environments, it is necessary to choose instruments that are dustproof and waterproof (IP65 and above), wide temperature working range (-20°C~80°C) and anti-electromagnetic interference.

5. Function expansion and data management

• Additional features: peak holding, data storage, statistical analysis (e.g. mean/standard deviation), automatic pass/fail judgment.

• Data interface: supports USB, RS232, Bluetooth and other transmission protocols, and is compatible with professional software to achieve measurement data recording and traceability.

6. Balance budget and cost performance

• High-end instruments (such as laboratory-grade dynamic Testers) are more expensive but availablelong-term stability and precision; Basic instruments are suitable for scenarios with limited budgets and average accuracy requirements.

epilogue

As a core tool in the field of industrial testing, the selection and application of Torque Testers need to be closely focused on the needs of specific scenarios. Whether it's ensuring the safe fastening of automotive components or optimizing the assembly process of electronic devices, accurate torque measurement is a key part of improving product quality. By understanding the working principle of the Torque Tester and mastering the core selection elements, users can efficiently match the instrument's performance with actual needs, providing reliable support for production process optimization and product quality control.