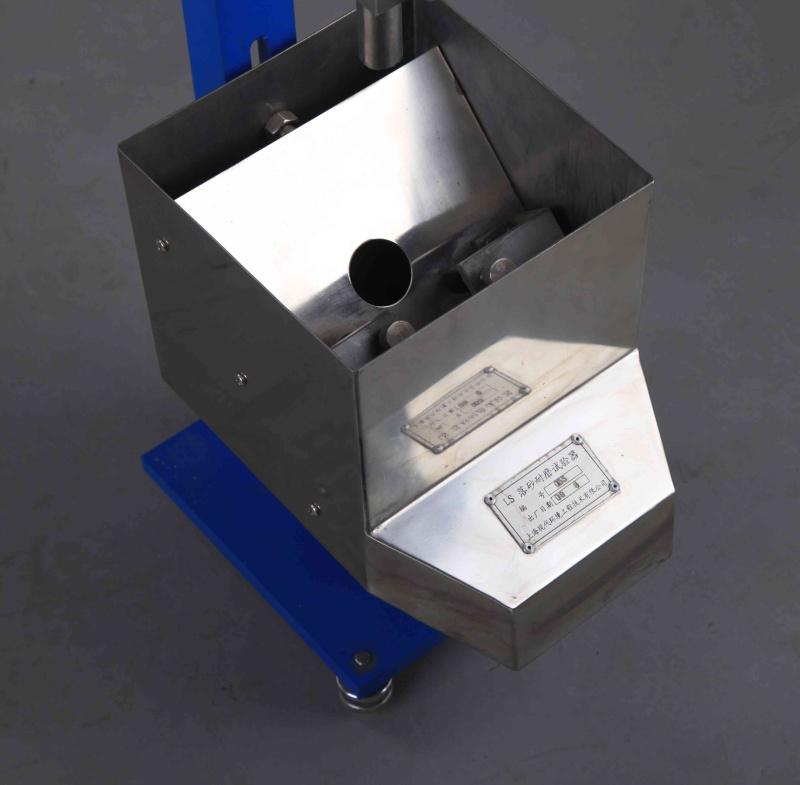

Falling Sand Abrasion Tester Comprehensive Analysis: Principles, Application Scenarios and Troubleshooting Guidelines

1. The working principle and technical characteristics of the sand wear Tester

The Sand Abrasion Tester is designed based on the gravity sand impact abrasion method, which impacts the surface of the material specimen in a rotating or stationary state at a controlled speed and angle by precisely controlling the vertical fall of standard abrasives (usually quartz sand or silicon carbide particles of a specific particle size) from a set height. This simulation realistically reproduces the wear process of materials in natural environments (e.g., wind and sand erosion) or industrial applications (e.g., mechanical friction).

Core working principle

The device drops the standard abrasive vertically from the specified height (typically 1 inch/approx. 25 mm) through a special conduit, which strikes the specimen surface at a standard rate. Four key parameters are precisely controlled during the test:

1. Abrasive Flow Rate: Adjust the sand falling rate through funnel outlet and conduit design

2. Impact height: Fixed impact distance in line with international standards

3. Specimen Status: Supports rotating or fixed test modes

4. Test Time: The duration of the standardization set based on the material's properties

Technical parameters and measurement indicators

By measuring the mass loss, thickness reduction, or amount of abrasive required for the specimen to be exposed under the impact of a specific abrasive, the wear resistance is finally expressed in quantitative indicators such as wear per unit film thickness or the number of wear revolutions. The test results are a direct reflection of a material's resistance to wear and tear, and are particularly useful for evaluating organic coatings, plastics, rubber, and metal finishes.

2. The core application areas of the sand wear Tester

With its reliable testing performance, this equipment plays a pivotal role in multiple industries, serving as an essential tool for material research and development and quality control.

1. Coatings and surface treatment industry

In the field of paint and coating manufacturing, the sand abrasion Tester is used to evaluate the ability of coating materials with different formulations to resist the impact of sand particles. Quality control of surface treatment processes such as electroplating and anodizing also relies on the test results of this equipment to ensure that the treated layer has sufficient wear resistance. Typical applications include:

• Wind and sand erosion testing of building exterior coatings

• Evaluation of wear resistance of floor paints

• Performance verification of industrial anti-corrosion coatings

2. Automotive industry applications

The device is widely used in automotive manufacturing to test the wear resistance of exterior trim coatings and interior materials:

• Coating impact resistance test of exterior trim parts such as bumpers and door handles

• Evaluation of wear resistance of plastic interior parts such as dashboards and door panels

• Comparison of wear resistance of tire rubber formulations

3. Construction and building materials industry

The wear resistance of building materials directly affects their service life:

• Surface wear resistance test of floor tiles and floor coatings

• Evaluation of surface treatment quality of aluminum alloy doors, windows and curtain walls

• Wind and sand resistance testing of exterior coatings for high-rise buildings and special environments

4. Plastics and rubber industry

Evaluation of wear resistance properties of industrial plastic components and everyday products:

• Abrasion resistance testing of seals, tires and other rubber products

• Improved surface wear resistance of plastic products

• Verification of friction resistance for everyday products

5. Aerospace and electronics

Special areas with extremely high requirements for material wear resistance:

• Abrasion resistance test of aircraft skin coating and porthole glass

• Performance evaluation of the landing gear protective layer

• Abrasion resistance testing of shell coatings of electronic and electrical products

3. Common fault diagnosis and maintenance solutions

Despite the precision of the device's design, it can still malfunction with long-term use. Mastering the solutions to common problems is crucial for ensuring test accuracy.

Power and start failure

Typical problems: the power indicator does not turn on, and the fuse burns when the power is turned on

Workaround:

1. Check the power supply line and input voltage (usually 220V/50Hz)

2. Replace the fuse of the same specification

3. Troubleshoot motor faults or circuit board short circuits

The machinery is running abnormally

Typical problems: abnormal noise, machine failure to operate

Workaround:

1. Add lubricating oil or replace the bearing when the bearing is out of oil

2. Check the motor wiring and counter status

3. Make sure the vacuum cleaner is properly connected

Test accuracy issues

Typical problems: the center of the sand flow is offset, and the sand falling speed does not meet the standard

Workaround:

1. Use the adjustment screw to calibrate the center position of the sand flow

2. Adjust funnel sand amount control device (standard is 21-23.5 seconds outflow of 2 liters of abrasive)

3. Check the fixed state of the specimen and the integrity of the fixture

Equipment maintenance points

1. Regular Cleaning: Clear blockages in conduits, clean funnels and valves

2. Component Inspection: Replace worn conduits and seals promptly

3. Daily maintenance: Keep equipment surfaces clean and lubricate moving parts regularly

Preventive maintenance recommendations

• Establish a regular inspection system to monitor the condition of mechanical components

• Operators need to receive professional training and be familiar with the principles of the equipment

• For complex faults, contact the manufacturer or professional maintenance personnel in time

4. Equipment selection and use suggestions

When selecting a sand drop wear Tester, the following key factors should be considered:

1. Test for Standard Compatibility: Ensure compliance with applicable standards like GB/T 1768

2. Test Range: Choose the appropriate model based on the material type

3. Degree of automation: Modern devices often come with digital displays and automatic timing features

4. Ease of maintenance: Consider the ease of cleaning and maintenance of the equipment

Proper use and maintenance of the sand wear resistance Tester can significantly improve the reliability and repeatability of test results, providing a scientific basis for the evaluation of material wear resistance.