Gel time meter: Definition, application and scientific selection guide

1. The basic concept of the gelatinization time meter

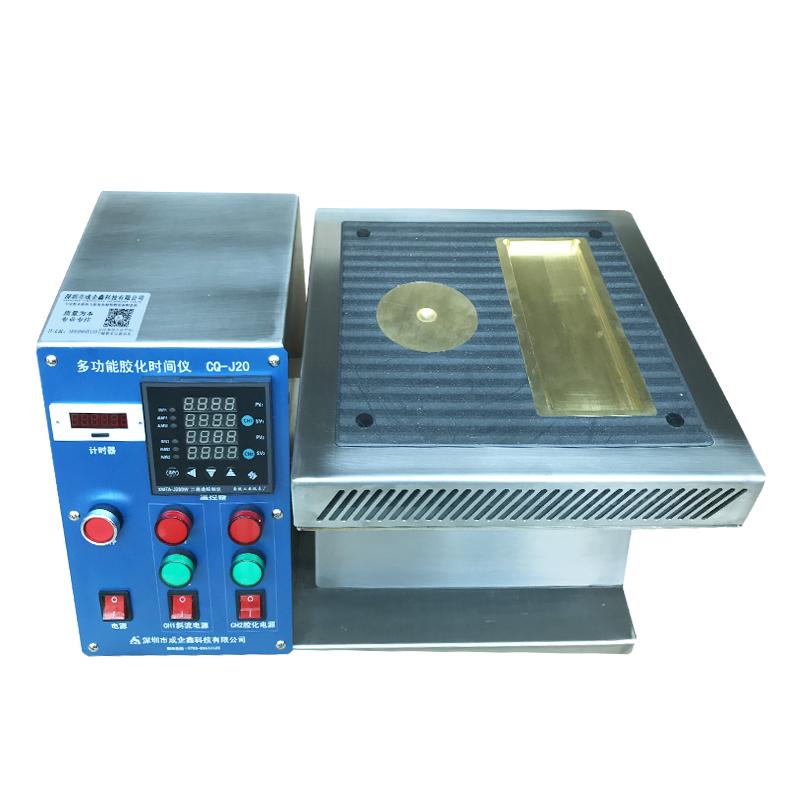

In materials science and industrial production, a gelling time meter is an inspection device used to accurately measure the time it takes for a material to change from a liquid or malleable state to a gel or solid state. This parameter is crucial for evaluating material properties, optimizing production processes, and ensuring product quality.

1. The basic principle of the gelling process

Gelatinization refers to the process in which the interaction between molecules gradually strengthens under specific conditions, forming a three-dimensional network structure, resulting in the loss of fluidity and increased hardness. For thermosetting materials (e.g., resins, coatings, adhesives, etc.), the gelling process is the core link in its transition from a processable state to an end-use state.

2. Core function of the gelling time meter

The gelling time meter monitors the changes in the material state by simulating the conditions of the material in actual use or production environment (such as temperature, stirring, etc.), so as to determine its gelling time. This time is usually defined as the moment when the material reaches a certain level of gel (e.g., significant increase in viscosity, loss of fluidity, etc.).

2. Application fields of gelatinization time meter

Gelation time meters are widely used in many industries, providing important data support for material research and development, production process optimization, and quality control.

1. Coatings industry

In coating production, gelling time directly affects the leveling, drying speed and final properties of the coating. By accurately measuring the gelling time, coating companies can adjust the formulation to ensure consistent product performance under different construction conditions.

2. Resin and adhesive industry

The key properties of resins and adhesives, such as curing speed and bond strength, are closely related to the gelling time. Gelatinization time meters help R&D personnel optimize material formulations and improve product applicability and reliability.

3. Other fields

In addition to coatings and adhesives, the gelatinization time meter is also suitable for plastics, rubber, electronic packaging materials and other fields, providing data basis for the improvement of material processing technology.

3. Key points for the selection of gelatinization time meter

Choosing the right gelling time meter requires a combination of factors to ensure that the equipment can meet actual testing needs and provide reliable data.

1. Clarify the type of material to be tested

Different materials (e.g., thermosets, powder coatings, adhesives, etc.) have different gelling properties, and it is necessary to choose an instrument that can simulate their actual processing conditions. For example, some materials may require specific temperature ranges or stirring methods.

2. Temperature control capabilities

Temperature is a key factor affecting gelling time, so the temperature range and accuracy of the instrument are crucial. Generally, temperature control accuracy of ±1°C or higher is required to ensure the accuracy of test results.

3. Test methods and principles

The gelling time meter can be used in a variety of measurement methods, such as viscosity change monitoring, flow observation, etc. Choose the right test method according to your actual needs to ensure that the data is representative and reproducible.

4. Stirring and sample processing

For tests that require agitation, the instrument's agitation speed, uniformity, and sample handling capabilities (e.g., sample volume, placement) can affect the test results. Choose equipment that can accommodate different sample characteristics.

5. Automation and intelligence level

Modern gelling time meters usually have functions such as automatic temperature control, automatic timing, and data recording, which can improve testing efficiency and reduce human error. Some high-end instruments also provide data analysis and report generation functions.

6. Stability and reliability

The long-term stability of the device directly affects the reliability of the test results. Choose instruments that have been proven by the market and have reliable performance, and pay attention to their quality certification and after-sales service.

7. Ease of operation and maintenance

Easy-to-operate instruments lower barriers to entry and reduce training costs. At the same time, the design that is easy to clean and maintain helps to extend the life of the equipment and reduce operating costs.

8. Cost and cost performance

On the premise of meeting the testing needs, it is necessary to comprehensively consider the price, function and long-term cost of the instrument to choose a cost-effective solution.

4. Summary

As a key equipment for material testing, the gelling time meter plays an important role in optimizing the production process and improving product quality. By accurately measuring the gelling time of materials, businesses can better control the production process and ensure that product performance meets expectations.

When selecting a gelling time meter, it is necessary to comprehensively evaluate factors such as temperature control, automation level, and stability based on material characteristics, testing needs, and budget to ensure that the equipment can provide accurate and reliable test data. In the future, with the continuous development of material science, the technology of gelatinization time meters will continue to be upgraded, providing more efficient detection solutions for more industries.