How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

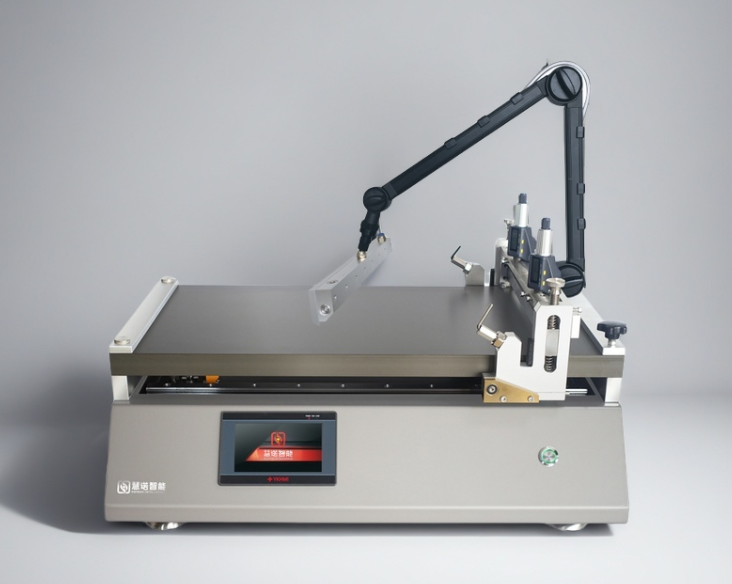

In cutting-edge research in materials science, the combination of nanoscale functional materials with flexible fabric substrates is giving rise to revolutionary applications such as smart clothing, flexible electronics, and advanced stealth technology. In this "combination of soft and hard" change, the coating machine has brought real convenience to the controllable preparation of new materials and performance optimization on flexible fabrics.

The coating machine realizes the precision and structure of the material,Compared with traditional simple impregnation and brushing, the core value of modern coating machines for preparing new materials on fabrics lies in "precision" and "controllability".

1. Precise thickness control

Through high-precision scrapers or wire rods, the coating machine can accurately control the thickness of the slurry coated on the surface of the fabric, with an accuracy of up to the micron level. This is essential for functional materials. For example, when preparing electromagnetic shielding or wave-absorbing fabrics, the thickness of the coating directly affects its dielectric constant and loss factor, which is a key parameter that regulates the frequency range of electromagnetic wave absorption. Too thin will not have enough performance, and too thick may affect the fabric's flexibility and increase costs, and the coating machine is a reliable means to find this "sweet spot".

2. Uniformity and consistency guarantee

The uniform speed of the coating machine ensures that functional slurries (e.g., graphene, carbon nanotubes, conductive polymer solutions) form a continuous, defect-free film on the surface of the fabric. This uniformity is fundamental to building efficient conductive networks or functional interfaces. A pinhole or a scratch can cause a surge in local resistance or the formation of electromagnetic wave reflection weaknesses, greatly reducing the overall performance of the material. The coating machine ensures a high degree of consistency and reliability in the performance of laboratory sample products.

3. Multi-layer structured design

Advanced functions often require multi-layered structures to be implemented together. For example, a conductive layer is applied first, followed by a precise dielectric or protective layer. The coater can easily achieve the sequential construction of this multi-layer heterogeneous structure with the thickness and uniformity of each layer, providing flexibility for design complex functions such as pressure sensing, compatible stealth, and energy harvesting.

- 1NVP anode film FAQ and solution

- 2Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 3Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 4Application and selection of laboratory coater in PDMS thin film prepative

- 5Scraping machine selection case: film substrate large size high accuracy scraping solution

- 6Application of Film Applicator in PEM Research and Preparation

- 7Application of Film Applicator in PVDF-HFP Material Research

- 8Application of Film Applicator in Cosmetic Base Body

- 9Application of Automatic Film Applicator in preparing fluorescent diaphragm