Contact Angle Meter Principle Application Selection Fault

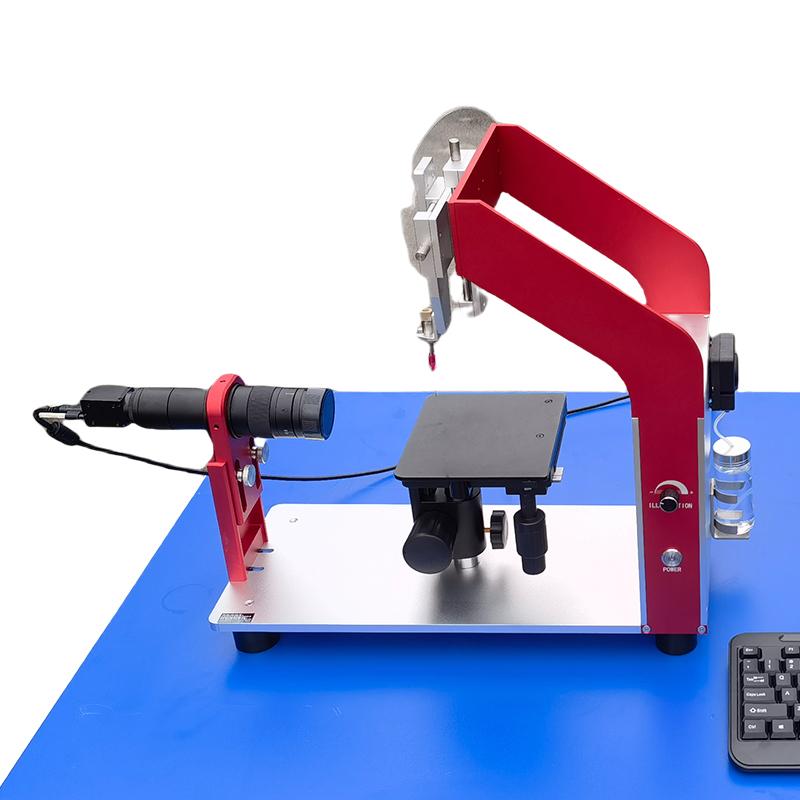

The contact angle measuring instrument is a precision analytical instrument to characterize the wetting performance of solid surfaces, which quantifies the surface tension interaction between solids and liquids by measuring the contact angle formed by liquids on solid surfaces, and then accurately judges the hydrophilicity, surface adsorption characteristics and modification effects of materials.

type

Classification according to the principle of measurement

Seat drop method: the most commonly used type, suitable for flat surfaces, thin films and other samples, easy to operate and stable accuracy, to meet most basic testing needs.

Suspension droplet method: suitable for measuring the surface tension of solids and liquids with low surface energy, and is calculated by the analysis of the contour of hanging droplets.

Capillary rise method: For porous materials such as powders and fibers, the contact angle is derived by using the liquid rising height.

Classified by degree of automation

Manual type: low cost, cumbersome operation, suitable for simple basic testing, scenarios that do not require high accuracy.

Semi-automatic type: core functions such as dripping and shooting are automated, and sample positioning needs manual assistance to balance accuracy and convenience.

Fully automatic type: Integrates automatic sample stage, precise dripping and AI analysis, supports multi-point and dynamic measurement, making it a reliable choice for scientific research and high-end quality inspection.

Test principle

The core is based on Young's equation (γSV = γSL + γLV·cosθ), where θ is the contact angle.

Use a microliter syringe to drip the standard liquid (commonly deionized water, ethylene glycol) on the surface of the solid sample to form stable droplets;

The high-speed camera takes pictures of the side contour of the droplet, and extracts the parameters through algorithms such as circle fitting and ellipse fitting.

Combined with the liquid surface tension data, θ<90° is hydrophilic, and θ>90° is hydrophobic, and the more extreme the value, the stronger the hydrophobicity.

Fields of application

Materials Science: Evaluate the surface modification effects of polymers, metals, ceramics, and other materials to optimize new material design.

Coating ink: Detect the wetting spreadability and adhesion of the coating to ensure the quality of printing and coating.

Electronic semiconductors: Detect the hydrophobicity of chip packaging materials and PCB boards to ensure the reliability of electronic components.

Other fields: waterproof and oil-proof testing of textile leather, rock wettability analysis of petrochemical industry, packaging and product suitability evaluation of food and daily chemicals.

Common faults and solutions

Blurry image: Due to lens contamination, insufficient light source, or improper focus, it is necessary to wipe the lens with anhydrous ethanol, adjust the brightness of the light source, and accurately focus on the edges of the droplets.

Large deviation of results: It may be that the droplet volume is unstable, there are impurities on the sample surface, or the algorithm is improperly selected, so it is necessary to calibrate the syringe, clean the sample surface, and select the algorithm according to the droplet shape.

Clogged / uneven droplets: Due to needle contamination, impurities in the liquid or bubbles in the line, needles need to be cleaned, the needle needs to be replaced, filtered liquid is used, and air bubbles are expelled.

Key points of selection

Matching accuracy requirements: scientific research scenarios require high-precision (≤±0.1°) fully automatic models to support dynamic measurement and complex fitting; Industrial quality inspection focuses on high repeatability (deviation ≤± 1°), and semi-automatic or fully automatic models are available.

Suitable sample types: flat sample selection drop method, porous/powder sample selection capillary rise method, special environment test requires customized models with temperature control and other functions.

Consider operation and function: novice or multi-person sharing preferentially choose fully automatic (one-click measurement, automatic data export); To calculate the free energy of the surface and analyze the dynamic contact angle, it is necessary to select the model with the corresponding module.

summary

The contact angle measuring instrument is the core equipment for material surface property analysis, which realizes the quantification of hydrophobicity based on Young's equation, and is suitable for different samples and scenarios. It is widely used in scientific research and innovation and industrial quality inspection in multiple industries, and is a key tool for product optimization and quality control. The selection should be combined with the sample type, precision requirements, functional requirements and budget comprehensive judgment, and through standardized operation and regular calibration in daily use, common faults can be effectively avoided and data reliability can be guaranteed. With the upgrading of technology, intelligent and multi-functional models are gradually becoming the mainstream, providing more accurate and efficient support for the development of various fields.