Initial Viscosity Tester comprehensive knowledge analysis: type, principle, application and selection guide

The initial tack tester is a special instrument for determining the initial adhesion properties of pressure-sensitive adhesive products (such as tapes, labels, etc.), and is widely used in quality control in adhesive-related industries to quantify the viscosity index by simulating actual contact scenarios. The initial tack tester is a testing equipment used to evaluate the adhesion ability of pressure-sensitive adhesive products under slight pressure and short contact, and its test results directly reflect the adhesion effect of the product in the early stages of use.

Main types

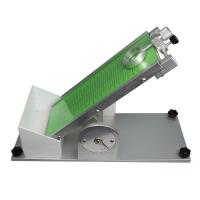

Initial Viscosity Tester of rolling ball method: the viscosity is determined by the rolling distance of the steel ball on the inclined specimen surface, which is easy to operate.

Inclined roller tester: standardized tilt angle (common 30°, 45°, 60°), suitable for most pressure-sensitive adhesive products.

Probe method initial Viscosity Tester: The probe touches the specimen and separates it, directly measuring the initial adhesion force, with higher accuracy.

Test principle

1. Prepare a standard-sized pressure-sensitive adhesive specimen and fix it in the designated position of the test bench.

2. Simulate the light contact scene in actual use (such as rolling ball rolling down, probe pressing) to make the test medium in brief contact with the specimen surface.

3. Quantify the initial viscosity grade or value by measuring key parameters (rolling distance, probe separation force).

Fields of application

Packaging industry - product quality testing such as tapes, self-adhesive labels, packaging films, etc.

Electronics industry - initial viscosity verification of adhesive and protective film for fixing electronic components.

Printing industry - adhesive control of printing adhesive and laminating materials.

Building materials industry - quality screening of adhesive building materials such as decorative films and waterproof membranes.

Common faults and solutions

Fault 1: The test results are highly biased.Workaround: Calibrate the horizontality and tilt angle of the instrument, replace the standard steel ball or probe, and ensure that the specimen surface is clean and free of impurities.

Fault 2: Instrument jamming (such as rolling ball track is not smooth).Workaround: Clean the track stains, apply special lubricating oil, and check whether the parts are loose.

Fault 3: The data shows instability.Workaround: Check whether the power supply voltage is stable, restart the instrument and recalibrate, replace the aging sensor.

Key points of selection

1. Match test standards: Select instruments with corresponding test methods according to industry specifications (such as GB/T 4852, ASTM D3121).

2. Suitable sample type: Thin film samples can be selected by rolling ball method, and thick glue or special-shaped samples can be preferred by probe method.

3. Clarify precision requirements: laboratory research and development needs to select high-precision (error ≤±1%) instruments, and conventional precision equipment can be selected for production line quality inspection.

4. Consider the usage scenario: choose portable instruments for on-site testing, and choose desktop multi-functional models for laboratory use.

summary

As the core equipment for the quality control of pressure-sensitive adhesive products, the type, principle and application scenarios of the initial tack tester are highly adapted to the needs of different industries. Through standardized testing processes, it can accurately quantify the initial adhesion properties of products and provide reliable data support for production, R&D and quality inspection. Mastering the troubleshooting methods and scientific selection logic of common faults can further improve testing efficiency and result accuracy, and help enterprises ensure product consistency and market competitiveness.