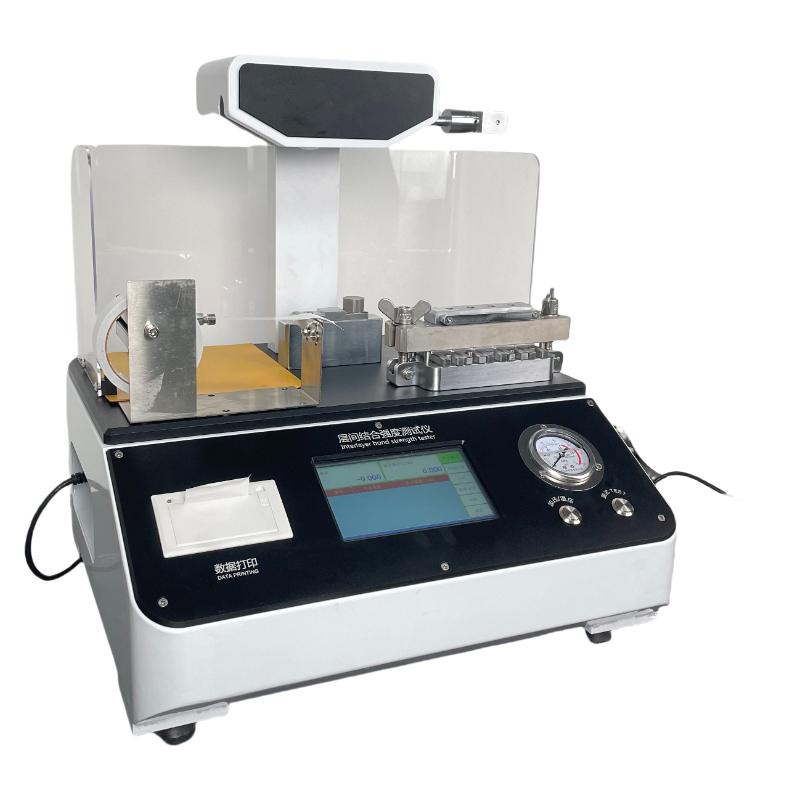

Interlayer bond strength tester comprehensive knowledge guide

The interlayer bond strength tester is a special instrument used to detect the bonding firmness between layers of multi-layer materials, and the core is to separate the materials between layers by a specific loading method, and then quantify their bond strength indexes.

Instrument type

1. Peel type measuring instrument: Achieve interlayer separation through vertical or angular peeling force, suitable for flexible multi-layer materials such as film and paper.

2. Shear measuring instrument: applies shear force in the parallel direction between layers, mostly used for rigid multi-layer structures such as plates and composite materials.

3. Tensile tester: Axial stretching of the specimen to promote tensile failure between layers, suitable for high-strength multi-layer material testing.

Test principle

The sensor will collect the force value change data in real time until the separation and failure between the layers of the specimen and record the maximum destructive force, and finally combine the size parameters of the specimen to calculate the interlayer bonding strength value according to the standard formula, which is usually measured in MPa or N/m.

Fields of application

1. Packaging industry: Inspect the bonding quality between layers of corrugated boxes, composite packaging films, aluminum-plastic composite panels, etc.

2. Printing and papermaking: Evaluate the bonding firmness of paper, cardboard, and printed laminated layers.

3. Composite material industry: Assess the interlayer properties of multi-layer structures such as carbon fiber composites and glass fiber reinforcements.

4. Building materials industry: suitable for quality inspection of layered building materials such as insulation boards, multi-layer gypsum board, and composite flooring.

Common faults and solutions

1. Inaccurate force value display: check the calibration status of the sensor and recalibrate the standard weight; Clean the sensor connection line to eliminate poor contact.

2. Unstable specimen clamping: Replace the clamp suitable for the specimen size and adjust the clamping force to avoid test deviations caused by over-looseness or tightness.

3. Abnormal loading speed: overhaul the drive motor and transmission system, and replace worn parts; Reset instrument speed parameters to ensure compliance with test standards.

4. Data cannot be saved: Check the storage module or software system, restart the instrument to return to normal; Back up the test software in a timely manner and reinstall it if necessary.

Selection method

When selecting, it is necessary to match the material characteristics first, preferably peel type for flexible materials, shear type or stretch type for rigid materials, and select the corresponding load range according to the thickness and strength of the material. Then refer to industry test standards, such as GB/T 6546 for the packaging industry, GB/T 26203 for the paper industry, etc., and choose instruments that meet the standard testing methods. In terms of core parameters, priority should be given to equipment with wide adjustable loading speed, high sensor accuracy (0.5 level and above recommended) and stable data collection. Finally, combined with the usage scenario, the laboratory can choose a desktop high-precision model for accurate testing, and a portable or online model can be selected for rapid inspection of the production line.

summary

As a key equipment for multi-layer material quality testing, the interlayer bond strength tester is divided into three categories: peeling, shearing and stretching, and quantifies the interlayer bond strength of materials through standardized force application and data calculation, and is widely used in packaging, printing and papermaking, composite materials and building materials and other industries. During use, it is necessary to solve common faults such as inaccurate force values and unstable clamping, and the selection needs to be combined with material characteristics, test standards, core parameters and usage scenarios to ensure that the test results are accurate and meet the actual application needs.