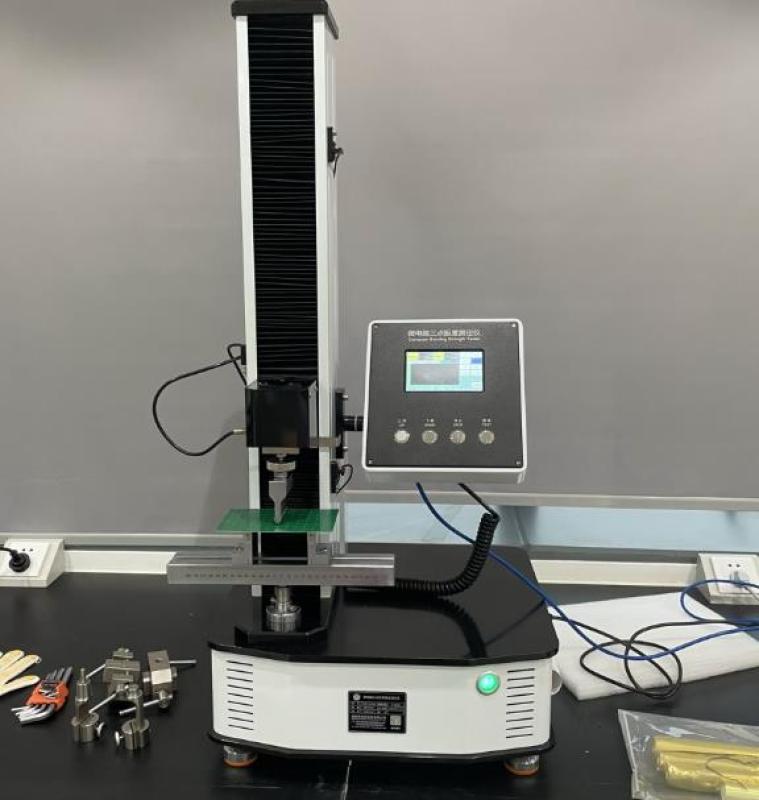

Flexural strength tester core knowledge guide

Flexural strength tester is a professional equipment to detect the ability of materials to resist bending deformation and fracture, by applying controllable bending loads and collecting mechanical parameters, providing data support for material research and development, production quality inspection, and widely used in the evaluation of material properties in multiple industries.

Core definition

The flexural strength tester is a testing equipment that applies bending load to materials, monitors deformation and load changes in real time, and then calculates key indicators such as flexural strength and flexural elastic modulus, which is suitable for material research and development, quality control and academic experiments.

Main types

Electronic: High precision, supports digital data storage, suitable for accurate laboratory testing.

Hydraulic type: strong bearing capacity, suitable for high-strength and large-specification material testing.

Microcomputer control type: realize automatic control and data analysis, take into account accuracy and efficiency, and are suitable for batch testing.

Test principle

The specimen is fixed on the clamping device according to the standard, the equipment applies a slowly increasing bending load, the sensor captures the load and deformation data in real time and transmits it to the control system, and the system automatically calculates the core parameters according to the mechanical formula to complete the evaluation of the flexural performance of the material.

Fields of application

It is widely used in construction materials, machinery manufacturing, plastics and rubber, composite materials and furniture manufacturing and other industries, and can detect various materials such as steel bars, mechanical parts, plastic plates, carbon fiber composite materials, etc., to ensure the safety of product structure and reliability.

Common faults and solutions

1. Inaccurate load data: calibrate sensors, check connection wires, and clean up impurities in components.

2. Equipment operation lag: lubricate the transmission mechanism and replace the worn and deformed transmission parts.

3. Abnormal data storage/export: Check the storage module connection, restart the system, and replace the faulty hardware.

4. Unstable clamping of specimens: adjust the clamping spacing and pressure, and replace the aging clamping pad.

5. Abnormal loading speed: Overhaul the drive components and recalibrate the loading speed control system.

Key points of selection

Match material properties – choose the right range and clamping device based on material type, specification and load range.

Follow industry standards - determine core parameters such as equipment accuracy and loading speed according to testing specifications.

Adapt to usage scenarios - the laboratory selects high-precision and multi-functional models, and the production line gives priority to automated and efficient equipment.

Pay attention to configuration and after-sales - give priority to equipment with automatic data analysis function, and pay attention to the manufacturer's after-sales guarantee.

Expand Space – Choose devices that are compatible with multiple fixtures and support upgrades to improve long-term utilization.

summary

Flexural strength tester is a key equipment for material property testing, with various types and clear principles, covering the testing needs of multiple industries. In practical applications, it is necessary to combine material characteristics, industry standards and usage scenarios to scientifically select types, and do a good job in daily maintenance and fault handling to ensure the accuracy of detection data and give full play to its supporting role in material quality control and product development.