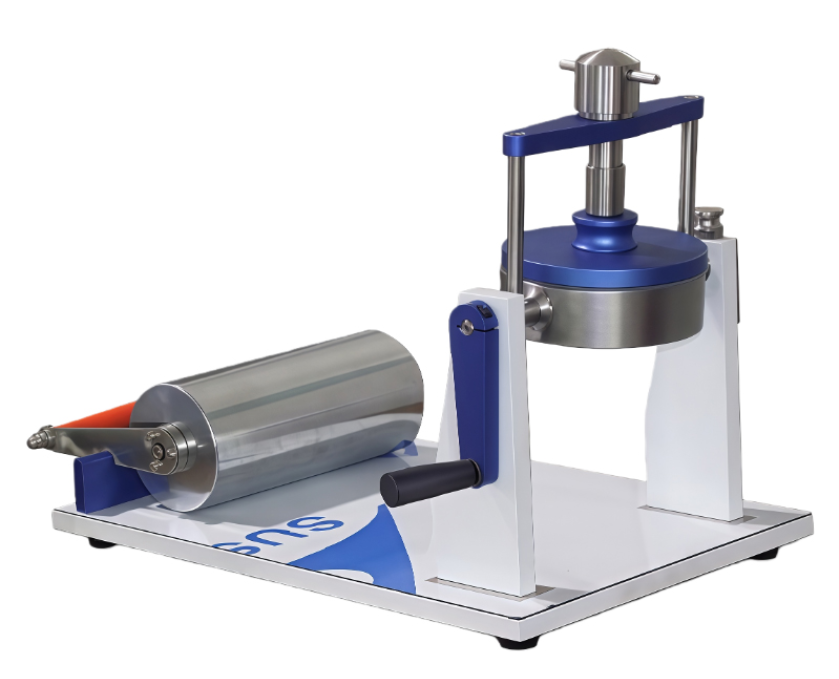

Cobb Water Absorbency Tester Type, Principle, Application and Selection Guide

Kebo water absorption tester is an industrial testing instrument used to quantitatively detect the water absorption performance of materials (especially film, paper, textile, leather, polymer materials, etc.), by simulating the water absorption process of materials under specific environmental conditions, accurately measuring water absorption, water absorption rate and other key indicators, providing data support for material quality control, performance evaluation and research and development, because the core testing principle and operation logic fit the needs of industrial material testing, it is widely used in related fields.

type

1. Classification by test method - static immersion type Cobe absorbency tester (completely immersion of the sample in the test liquid, suitable for routine water absorption test), dynamic contact type Cobe absorbency tester (simulating the dynamic contact of liquid samples, suitable for water absorption evaluation in special use environments).

2. Classification according to the degree of automation - manual type (manual sample placement, timing, weighing and other operations need to be completed manually, low cost, suitable for small businesses or simple testing scenarios), semi-automatic type (automation of some steps, such as automatic timing, automatic calculation of data, taking into account cost and efficiency), fully automatic type (integrated automatic sample grabbing, soaking, drying, weighing, data recording and analysis functions, high test accuracy and high efficiency, suitable for large-scale production quality inspection or scientific research institutions).

3. Classification according to test medium - water quality absorption tester (with distilled water and deionized water as the test medium, the most widely used), special medium type (acid and alkali solution, salt solution, etc. as the test medium, suitable for material detection under specific working conditions).

Test principle

The core principle is based on the law of conservation of mass and the water absorption characteristics of the material, by measuring the mass change of the sample before and after the test, and calculating the water absorption index in combination with the initial parameters of the sample.

Specific process

1. Prepare a standard size sample and accurately weigh the initial mass (m₀) after drying

2. Set the test conditions according to the test standards (such as GB, ISO, ASTM, etc.), including soaking temperature, soaking time, liquid type, sample contact method, etc

3. Place the sample in the test medium and hold it under the specified conditions until the set time

4. Remove the sample, remove the excess liquid from the surface, and quickly weigh the water absorption mass (m₁)

5. The instrument automatically calculates the water absorption rate (W=(m₁-m₀)/m₀×100%), water absorption rate (V=(m₁-m₀)/(m₀×t), t is the soaking time) and other indicators, and some high-end instruments can synchronously record the mass change curve during the water absorption process

Fields of application

Film making industry - used to test the water absorption of plastic films, composite films, breathable films and other products to ensure that the film has moisture-proof or water-absorbent properties that meet the requirements in packaging, protection and other applications.

Paper & Printing Industry – Testing the absorbency of paper, cardboard, and printing substrates affects print suitability, paper strength, and storage stability.

Textile and leather industry – evaluating the absorbent and breathable properties of fabrics and leather, which is related to the product experience such as wearing comfort and durability.

Polymer materials industry - used for water absorption testing of rubber, plastic, resin and other materials, providing a basis for material formulation optimization and product quality control.

Scientific research and quality inspection institutions - as the core equipment of material performance testing, it is used in scenarios such as new material research and development, product quality supervision and inspection, and industry standard formulation.

Other fields - such as building materials (waterproof membranes, insulation materials), medical materials (medical dressings, disposable consumables), etc.

Common faults and solutions

The weighing results are inaccurate

The fault causes include the balance is not calibrated, the excess liquid on the sample surface is not removed, and the temperature and humidity fluctuations in the test environment are too large.Workaround-Calibrate the electronic balance regularly, use standard methods (such as filter paper blotching, cold air drying) to remove the liquid on the surface of the sample, and place the instrument in a constant temperature and humidity laboratory.

Abnormal water absorption data (high or low)

The reasons for the failure include the sample size not meeting the standard, the soaking time does not reach the set value, and the purity of the test medium is not up to standard;Workaround-Prepare samples in strict accordance with the test standards, check whether the timing function of the instrument is normal, and replace the test medium that meets the requirements (such as distilled water must comply with GB/T 6682 standards).

Instrument leakage (static immersion)

Failure causes include aging seals, broken sample containers, and loose tubing connections;Workaround-Replace the aging sealing ring or gasket, check the container for cracks and replace it in time, and fasten the pipeline connection.

Data cannot be automatically recorded or calculated

Fault causes include software failure, poor sensor connection, and incorrect parameter settings;Workaround-Restart the instrument and update the software, check the connection between the sensor and the host, and reset the test parameters according to the operation manual.

How to choose

Choose the corresponding test method (static or dynamic) according to the type of test material (e.g., film, paper); If you need to test special media (such as acid-base solutions), you need to choose an instrument with strong corrosion resistance.

Instruments with an accuracy of 0.01g can be selected for industrial production quality inspection, and equipment with higher accuracy (such as 0.001g) should be selected for scientific research institutions or high-end product testing.

Manual testing can be selected to control costs, and it is recommended to choose fully automatic type for large-scale batch testing to improve testing efficiency and reduce human error.

The number of test stations (single station or multi-station) of the instrument is selected according to the number of test samples per day, and the multi-station instrument can perform multiple sample tests at the same time, saving time.

Ensure that the sample size supported by the instrument meets the requirements of the test standard, and if you need to test a special size sample, choose an instrument that can customize the sample fixture.

Choose a brand with professional technical support, regular calibration services, and wearing parts supply to ensure the long-term stable operation of the instrument.

Prioritize instruments that comply with mainstream industry standards (such as GB/T 1034-2008, ISO 62-2008) to ensure the versatility and reliability of test data.

summary

The absorbency tester is the core equipment for the water absorption detection of industrial materials, which can be divided into various types according to the test method and automation degree, and is widely used in filmmaking, papermaking, textile and other fields. During use, it is necessary to pay attention to common faults such as weighing accuracy and data stability, and the selection should be combined with key factors such as testing requirements, accuracy requirements, and automation to ensure that the instrument is suitable for practical application scenarios and provide reliable support for material quality control and research and development.