Deguang DC-4000 Intelligent Ultrasonic Thickness Gauge Operation Instructions

1. Overview

The DC-4000 Intelligent Ultrasonic Thickness Gauge is an automated Thickness GaugeThe A- and B-scan Thickness Gauges, using microprocessor technology, utilize the ultrasonic measurement principle, can be:It is used to measure the thickness and sound velocity of metals and other materials.Before using the instrument, please read this user manual thoroughly in order to understand the functions of the instrument.Master how to use the instrument.

Second, technical parameters

Display: 320X240 color TFT dot matrix liquid crystal display

Number of digits: 4 digits

Measuring range: 0.65mm~400.0mm

Indication accuracy: ±0.1mm (measurement greater than 100mm), ±0.01mm (measurement less than

100mm)

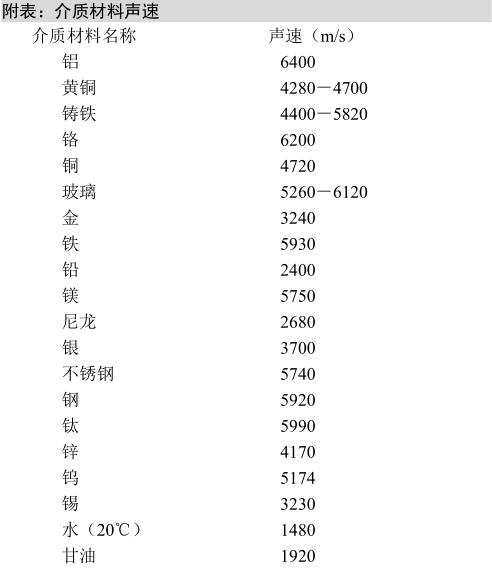

Sound velocity range: 1000~9999m/s

Measurement frequency: 2 times/sec for normal measurements

High-speed measurement of 10 times/second

Auto shutdown time: 1 minute, 3 minutes, 5 minutes

Power supply: two No. 7 (AAA) batteries, which can work continuously for no less than 24 hours.

Environment: Temperature: -20°C~60°C

Storage temperature: -20°C~50°C

Dimensions: 133mm(L)×75mm(W)×29mm(H)

Weight: 260g (including battery)

Optional Accessories:

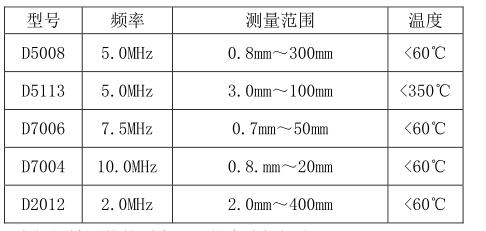

Probes: D5008, D5113, D7006, D7004, D2012

3. Measurement principle

The ultrasonic pulse is passed through the couplant by the probe to the measured body, and part of it is surfaced by the objectSurface reflection, the probe receives the echo reflected by the ground of the test object, and accurately measures the ultrasonic wave on the subjectThe round-trip time in the object is measured, the thickness is calculated, and then displayed numerically.

(1) LCD panel

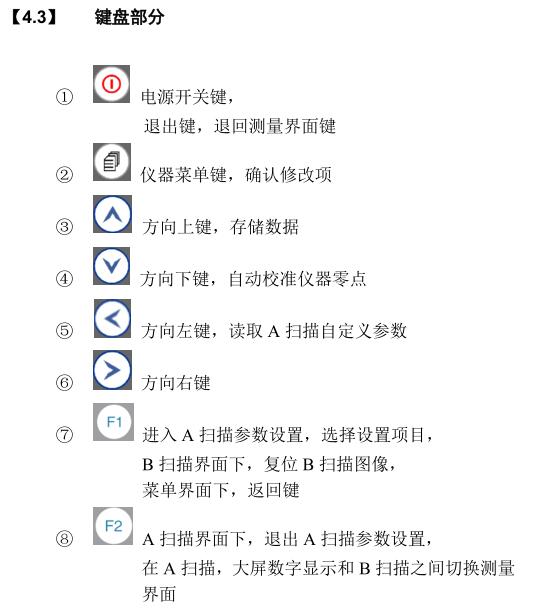

(2) Keyboard

(3) Battery compartment (back)

(4) Instrument Plate (Back)

(5) Probe socket and identification pin

(6) Calibration test block

(7) USB data transmission interface

5. Preparation before measurement

[5.1] Instrument preparation

Please refer to the following standard configuration for newly purchased instruments, check the instruments and accessories, and please timely when it is incompleteContact the manufacturer; If the instrument is damaged, do not use it and contact the manufacturer as soon as possible.

The main unit is DC-1000C

One probe D5008

COUPLANT 75ML IN A BOTTLE

Instrument case 1

One copy of the manual

No. 7 battery 2 cells

[5.2] Probe selection

The user selects the probe according to the thickness and shape of the measured body.Model D5008 Probe: This probe can be selected in a variety of situations. For example, the measuring surface is flator a large arc, and the thickness of the test body exceeds 50mm.

Model D5113 probe: for the measurement of materials with temperatures less than 350°C.

Model D7006 probe: mainly used for thin-walled and small-cambered measurements.

Model D7004 probe: mainly used for thin-walled and small-curved measurements.

Model D2012 probe: Mainly used for the measurement of coarse-grained materials such as cast iron.

[5.3] Treatment technology of the surface of the measured object

If the surface of the test object is rough or severely corroded, please treat it with the following methods:

1. Use rust remover, wire brush or sandpaper to treat the surface of the measured body;

2. Use more couplant on the surface of the test body;

3. Measure multiple times near the same point.

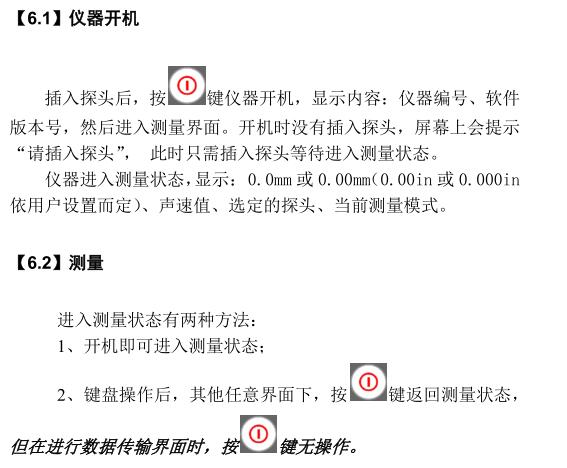

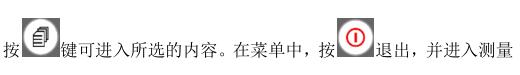

6. Functional application of the instrument

7. Measurement application technology

[7.1] Measurement method

A variety of reference measurement methods are available:

1. Single-point measurement method, at any point on the measured body, use the probe to measure, and the displayed value is thickDegree value.

2. The two-point measurement method uses a probe to measure twice at the same point of the measured body, the probe is divided by 90 degrees, and the smaller value is the thickness value.

3. Multi-point measurement method, take multiple measurements in a circle with a diameter of about 30 mm, whichever is the smallestThe value is the thickness value.

4. Continuous measurement method, using a single-point measurement method, continuous measurement along the designated line, and its interval is not smallat 5 mm, the minimum value is the thickness of the measured body.

[7.2] Pipe wall measurement method

When measuring, the probe split surface can be measured along the axis of the tube or the axis of the vertical tubeMeasure. If the pipe diameter is large, the measurement should be measured in the direction of the vertical axis; The diameter of the pipe is small, and it should beMeasured in two directions, the smallest value is the thickness value.

8. Maintenance and precautions

[8.1] Power supply check

When the power supply voltage is low, the instrument displays a low voltage symbol, which should be replaced in time as requiredbattery, so as not to affect the measurement accuracy. The backlight should not be turned on for a long time so as not to consume power too quicklyPool power. If the instrument is not used for a long time, take the battery out of the battery compartment to avoid the battery being damaged by the batteryLeakage erodes the circuit board.

[8.2] Precautions

1. General precautions

Avoid strong vibration of the instrument and probe; Avoid placing the instrument in an excessively wet ringin the environment; When inserting and unplugging the probe, the movable jacket should be pinched and applied force along the axis, and the probe should not be rotated.to avoid damaging the probe cable core.

2. Precautions should be taken in measurement

(1) When measuring, it is a good measurement only when the measurement indicator appears and is stable.

(2) If there is a large amount of couplant on the surface of the test body, when the probe leaves the surface of the test body,The couplant can cause false detections, so at the end of the measurement, the probe should be quickly removed from the body surfaceFace.

(3) If the probe is worn, the measurement value will be unstable, and the probe should be replaced.

- 1Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- 2Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 3Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 4Principle, Application and Selection of Ceramic Ultrasonic Thickness Gauge

- 5The Principle, Application and Precautions of Copper Plate Ultrasonic Thickness Gauge

- 6Principle and Application of Ultrasonic Thickness Gauge

- 7Application scheme of coating thickness test on wood board [with test video]

- 8PosiTector200C ultrasonic coating Thickness Gauge on concrete coating thickness measurement application

- 9Measurement principle and influencing factors of high temperature ultrasonic Thickness Gauge