Coating performance measurement summary

1. Covering power

Hiding power refers to the ability of the color paint to be evenly applied on the surface of the object to cover the background color of the surface of the coated substrate. Black and white grid tests are often used, and it is expressed by the minimum amount of paint per unit area to cover the background color (g/m2).

According to the regulations of GB/Tl726-89, the method of brushing or spraying on the surface of the black and white grid glass plate is adopted, and the disposable black and white grid paper is used abroad, which is more convenient to use. (Related equipment: covering power paper)

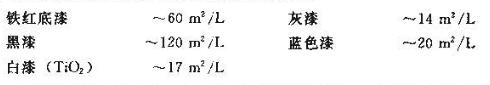

The hiding power of the paint depends on the degree of light scattering and absorption of the pigment, and is also related to the difference in refractive index between the pigment and the base material. The higher the hiding power, the larger the construction area of the paint, and the unit of several types of paint Examples of volume and construction volume are as follows:

For white and light-colored paints, a reflectance meter can also be used to measure the ratio of the reflectance of dry films of different thicknesses on blackboards and whiteboards, that is, the contrast ratio. When the contrast ratio is equal to 0.98, it is considered that the paint film of this thickness is fully covered, and the hiding power can be calculated according to the thickness.

2. Leveling and sagging

The leveling and flow tracing properties of the paint film can be scraped with a saw-toothed section board, and the leveling ability or resistance of the paint can be evaluated by observing that the adjacent paint strips whose thickness changes sequentially flow together or not flow together or not flow together. Sagginess. (Related instruments: Sag Tester)

Leveling and anti-sagging are a pair of contradictions. For coatings with excellent general properties, they have good leveling ability and anti-sag property after construction. The coating film is smooth and smooth, with uniform film thickness and good decorative appearance.

3. Grinding property (GB/T1770-89)

Because in the process of painting, it is always necessary to carry out local grinding and repairing; for the surface of old paint film or putty, effective overall grinding is required. Therefore, grinding is a process required in the painting process. The difficulty of grinding directly affects the construction efficiency. Generally, the grinding performance is judged by the degree of sanding when sanding or the difficulty of smoothing. If you feel greasy when you sand heavily, it is not easy to sand and smooth , the grinding performance is poor. For example, use 300' water sandpaper to polish 30 times to see if it is easy to polish and not roll; or use 200' water sandpaper with a weight of 200g to polish 100 times and it should be polished smoothly. Usually, the hard coating film has Good sandability, soft paint film has poor sandability. (Related instrument: Grinding Tester)

4. Recoatability

Recoatability refers to whether the second coat has problems such as bottoming, bleeding, unevenness and poor bonding force on the bottom layer within the specified time interval. (Related instruments: adhesion Tester)

Undercutting, bleeding, and unevenness are usually due to improper use of paints, or too short painting intervals; too long painting intervals or heavy methods on old paint films are prone to poor bonding.

Therefore, when the composite coating system or multiple coats are applied, the reproducibility is a very important construction performance. Of course, the recoatability can be improved by adjusting the construction process conditions.

- 1Professional analysis of Abradability Testers: a complete guide to definitions, types, and applications

- 2Summary of determination methods for hiding power of coatings

- 3Pigment hiding power

- 4Determination of Coating hiding power

- 5Waterborne architectural coatings detection method

- 6GB/T 23981.2-2023: Paints and varnishes - Determination of hiding power - Part 2: Checkerboard method - Interpretation

- 7Coating performance testing: leveling & sagging

- 8Summary notes on the determination of film sanding

- 9Determination of sanding property of paint film