Film Film thickness detection method

According to the state of the coating film, thickness measurement is divided into wet film thickness and dry film thickness detection.

l) Determination of wet film thickness

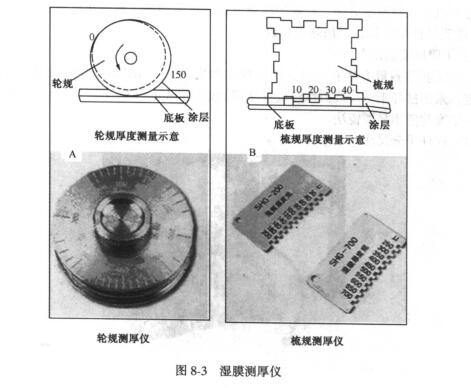

The wet film thickness measurement needs to be carried out immediately after the coating film is prepared to avoid shrinkage of the coating film due to solvent volatilization. There are three commonly used wet Film Thickness Gauges: wheel gauge, comb gauge and Pfund wet film gauge.

① Wheel gauge: The structure of the wheel gauge is shown in Figure 8_3 (A). It is composed of two discs of equal diameter and an eccentric circle sandwiched between them. There are scale lines on the outer side of the disk, the tangent point is zero, and the scale value at the opposite point is maximum.

When measuring, the wheel gauge needs to be perpendicular to the surface of the coating film and cannot shake; when the wheel gauge rolls on the surface of the coating film, it should start from the largest gap (scale) so that the coating film will not be pushed and squeezed, and the measured value is more accurate. If starting from zero, the wet film will be pushed, and the error of the measured value will be large.

② Comb gauge: The structure of the comb gauge is shown in Figure 8-3(B). It is a square or rectangular sheet made of metal or plastic, the two ends of each side are on the same plane, and there are different gaps between the bottom edge of each tooth in the middle and the horizontal plane, that is, the scale, to indicate the thickness of the coating film value.

When measuring, put the comb gauge vertically on the surface of the coating film, a part of the teeth are wetted by the coating film, and the reading between the last tooth that is wetted and the tooth that is not wetted is the thickness of the measured coating film value. The film thickness shown in the picture is 30µm.

③Pfund wet film meter: It is composed of a convex lens (with a radius of curvature of 250mm) and two metal circular tubes. The measurement principle is to press the measuring tube on the wet film, make the convex lens installed at the bottom of the tube contact with the wet film, and then convert the thickness of the wet film through the diameter of the adhered part. Calculated as follows:

With this measurement method, due to the surface tension of the wet film, the measured thickness is different from the actual one, and a correction factor needs to be quoted. For details, see the content of the US ASTMD1212-79 standard.

Combining the above several measurement methods, the measurement of the wheel gauge is convenient and the reading is accurate. Although the comb gauge is simple, it has a large error. The Pfund wet film meter is inconvenient to use, and a correction factor needs to be added.

2) Determination of dry film thickness

There are two methods of measuring dry film thickness, namely magnetic method and mechanical method. According to the provisions of GB1764-79 "Determination of Paint Film Thickness", it is measured with a lever micrometer or a magnetic Thickness Gauge, unit: µm. IS()2808-l974 "Measurement of Paint Film Thickness" recommends the use of microscopy.

(1) Lever micrometer method (see Figure 8-4 for the instrument)

① Calibration of the "0" position of the lever micrometer: first clean the two measuring surfaces with a silk cloth, rotate the micrometer cylinder so that the two measuring surfaces lightly touch each other, and stop rotating when the pointer coincides with the "0" line on the dial. The "0" line on the differential cylinder should also coincide with the axial engraved line on the fixed sleeve, the edge of the differential cylinder is exactly tangent to the left edge of the "0" line of the fixed sleeve, and the "0" position is correct; otherwise, it should be be adjusted.

Adjustment method: first align the pointer with the "0" on the dial, fix the movable measuring rod, loosen the back cover, then adjust the "0" line on the micrometer cylinder to coincide with the engraved line on the fixed sleeve, and make the micrometer cylinder The edge is exactly tangent to the left edge of "0" on the fixed sleeve, then tighten the back cover, loosen the movable lever, and check whether the dial pointer is on "0", if not, repeat the above steps.

②Measurement of thickness: Measure the upper, middle and lower parts not less than 1cm away from the edge.

a. First place the unpainted bottom plate between the micro-movement measuring rod and the movable measuring rod, slowly rotate the micrometer cylinder so that the pointer is between the two tolerance zones, and then adjust a certain line on the micrometer cylinder to the specified sleeve. The engraved lines on the barrel coincide. When reading, add up the value read on the fixed sleeve, emblem and dial to get the measured thickness value. In order to eliminate the error, the measurement can be repeated several times at the same point.

b. Apply the paint to be tested on the base plate that has been measured, and after drying for a specified time, use the same method to measure at the same position to obtain the thickness value.

c. The difference between the two values is the thickness value of the coating film at this point. Take the arithmetic mean of the thickness of each point, which is the average thickness of the coating film. Of course, it is also possible to measure the thickness value of the sample with the coating film first, and then take appropriate measures to remove the coating film at the measurement point to measure the thickness of the bottom plate, and the difference between the two is the thickness value of the coating film.

The advantage of this method is that it is not affected by the properties of the substrate and the conductive or magnetic pigments in the paint, and the measurement accuracy is high, up to ±0.002mm. However, it can only measure a small area of the sample, and the measurement procedures are cumbersome.

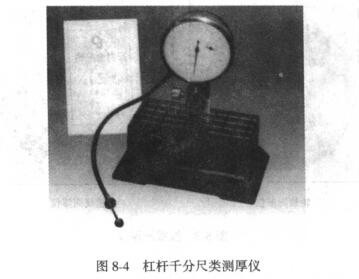

(2) Magnetic Thickness Gauge measurement method

The magnetic method has become the main method of dry film thickness measurement. The magnetic Thickness Gauge mainly uses the magnetic field reluctance principle to measure the coating thickness on the steel base plate. Figure 8_5 is the appearance of the coating thickness measuring instrument. A and B in the figure are transliterated as mil thickness measuring instrument because the measurement unit is mi1 (1mi1=0.0254mm). There are three types of mil Thickness Gauges: pen type, common type (A in the picture) and electronic type (B in the picture). C in the figure is HY-1 Thickness Gauge (magnetic and non-magnetic).

Pencil Mil Thickness Gauges have springs and mil thickness markings. When measuring, put the attached magnet end against the car body coating, pull the Thickness Gauge to display the thickness mark value, and measure according to the order of ①, ②, ③ shown in the figure. The electronic mil Thickness Gauge can automatically display or record the coating thickness.

The measuring range of HY-1 magnetic Thickness Gauge has four gears: 0~50µm; 0~100µrn; 0~250µm; 0~ 500µm.

The existing permanent magnets have been used to replace the electromagnetic field, which makes the magnetic Thickness Gauge compact and portable, but the accuracy is poor . The magnetic Thickness Gauge with dry battery or rechargeable battery is also compact in structure, easy to carry, and has high thickness measurement accuracy. More professional ones have been developed to digital display, which can directly read out the measured data, and are suitable for surface measurement of various shapes.

The non-magnetic Thickness Gauge uses the principle of eddy current to measure the coating thickness on the surface of aluminum plate, copper plate and zinc plate.

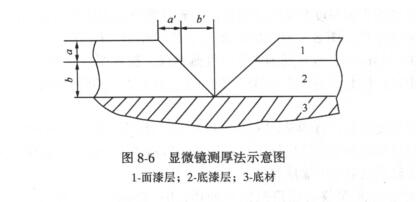

The ISO2808-1974 "Determination of Paint Film Thickness" standard recommends the use of microscopy, and its testing principle is shown in Figure 8_6. This method is to use a cutting tool at a certain angle to cut the coating into a V-shaped notch to the substrate at one time, and then use a microscope with a ruler to measure the thickness of a' and b'. The division of the scale has been converted into the actual thickness (µm) of the corresponding a and b through the calibration coefficient.

The biggest advantage of this method is that in addition to measuring the total paint film thickness, it can also measure the thickness of each layer of the multi-layer paint system, and it can be carried out on any substrate.

-

-

-

-

DONGRU DR120 Coating Thickness Gauge$ 168.00

-

-

-

-

-

- 1Performance Test and Characterization of Polyacrylate Mixed Suspension

杨庆臣 - 《北京化工大学》

- 2How to control the temperature of Spreader solution?

- 3What is the main role of talc in coating powder?

- 4Film Film thickness measurement

- 5Coating Film thickness

- 6Selection and comparison of several domestic (CN) magnetic metal substrate Thickness Gauges

- 7Difference and comparison of Lantai Thickness Gauge CM8822, CM8821 and CM8820

- 8Comparison of three popular coating thickness measuring instruments under 1,000 yuan

- 9Motorcycle film mass inspection?