Preparation method of coating mechanical performance test plate

Before the performance test of the coating, the test coating should be prepared according to the provisions of the national standard GB1727-79 "General Preparation Method of Paint Film". Methods as below:

(1) Floor surface treatment:

Depending on the material of the bottom plate, different processing methods are selected.

①The tinplate or steel plate shall be polished and derusted with No. 0 emery cloth or No. 200 water sandpaper (machinically or manually) to remove the tin-plated layer. Wipe off with solvent and dry before use.

②The glass plate is washed with hot soapy water, rinsed with clean water, and wiped dry. The surface should be wiped clean with solvent before painting and allowed to dry before use.

③The aluminum plate can be wiped clean with a solvent and dried.

(2) Plate making method:

Before painting, the paint sample should be fully stirred, filtered with a sieve if necessary, and then the coating film should be prepared according to the specified standards of the paint product.

① Brushing method: Dilute the product sample to the specified viscosity value, and use a paint brush to quickly and evenly brush in both vertical and horizontal directions on the specified bottom plate to form a uniform coating film without missing or flowing. Hanging and other defects. Put the brushed sample in a constant temperature and humidity place or dry it in a blast-type constant temperature Drying Oven.

② Spraying method: Dilute the sample to the specified construction viscosity value (under the condition of 25±1°C, measure it with a 4 viscometer. The oil-based paint is 20~30s; the volatile paint is 15~25s). Then spray it on the specified bottom plate to form a uniform paint film, without blank or sagging. Dry the sprayed sample in a constant temperature and humidity place or in a blast-type constant temperature Drying Oven.

③ Dip coating: Adjust the product sample to the specified viscosity value, then dip the base plate vertically into the paint at a uniform and slow speed, stay for 30 seconds, take it out at the same speed, and drip dry in a clean place for 10-30 minutes. Dry the samples under constant temperature and humidity conditions. If there is no regulation on the drying time for the first time, then it should be further ensured that no defects will appear in the second dip coating. Turn the sample panel upside down 180°, then carry out the second dip coating according to the first method, and let it drip dry for 10~30min. Dry according to the conditions specified by the product.

Before drying the sample, sufficient drying time should be left to avoid defects during the drying process, affecting the quality of the coating, and thus affecting the detection accuracy. The drying time of the sample is stipulated: the natural drying paint should be dried under constant temperature and humidity conditions for 48 hours, and the volatile paint should be dried for 24 hours; after the drying paint is dried according to the time specified by the product, it should also be placed under constant temperature and humidity conditions. 0.5~lh.

Constant temperature and humidity refers to: temperature (25 ± l) ℃, relative humidity of 65% ± 5%. (Related instruments: constant temperature and humidity Test Chamber)

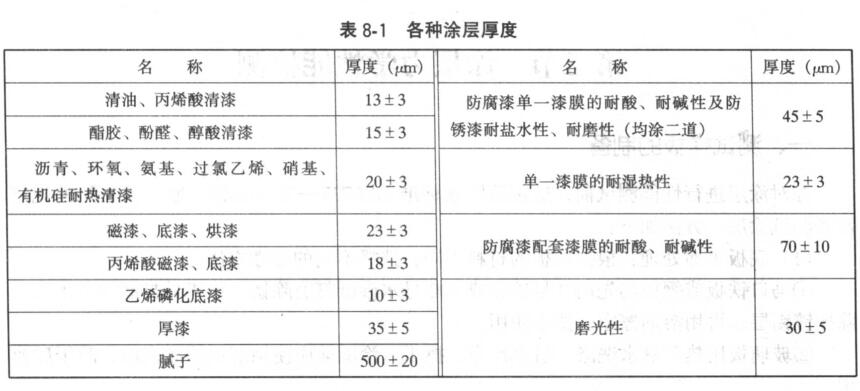

The coating thickness requirements (different types of coatings) for various samples after preparation are shown in Table 8-1.

- 1Preparation and Performance Test of Ultraviolet Curable Urushiol-Based Epoxy Acrylate Coatings

路正鸿 - 《西北农林科技大学》

- 2Resin superhydrophobic nano-titanium dioxide coating and its prepative performance

马丽;安秋凤;许伟;董晓红 - 《电镀与涂饰》

- 3Film mechanical performance testing instrument category summary

- 4Lame plating technology

- 5How to choose car lame plating equipment?

- 6Application of Miscellaneous lame plating technology in medium coating and topcoat

- 7Principles for choosing a lame plating process

- 8Introduction to the principle and characteristics of lame plating

- 9Factors affecting the volatilization of manual lame plating solvent on workpiece